Drill ship for deep sea intervention operations

a deep sea intervention and drilling vessel technology, applied in the direction of fluid removal, pipe-laying vessels, floating buildings, etc., can solve the problems of damage to stability regulations, ship exceeds the mobile offshore drilling unit passenger vessel intact, etc., and achieves low fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Hull and Main Ship Design

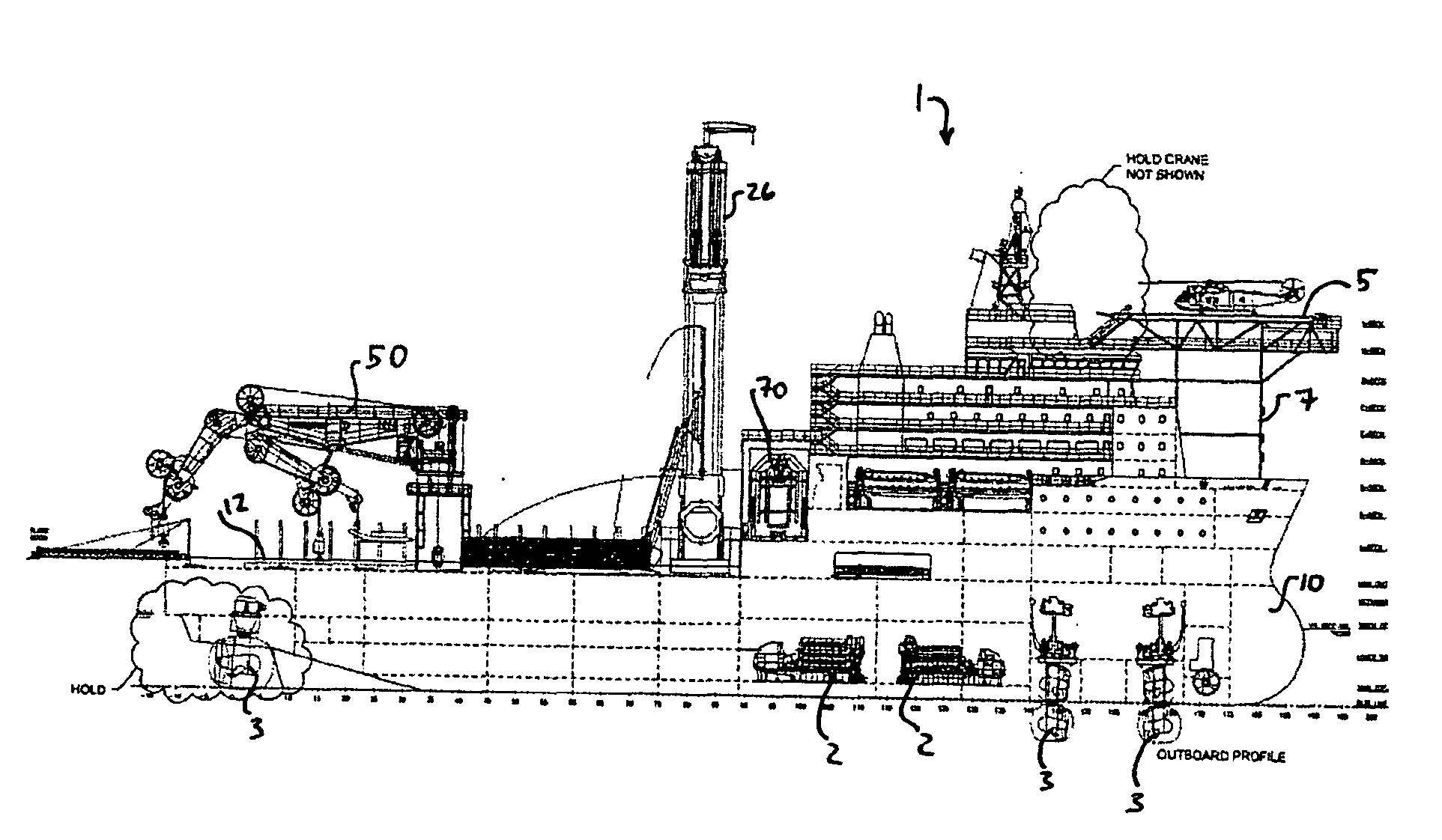

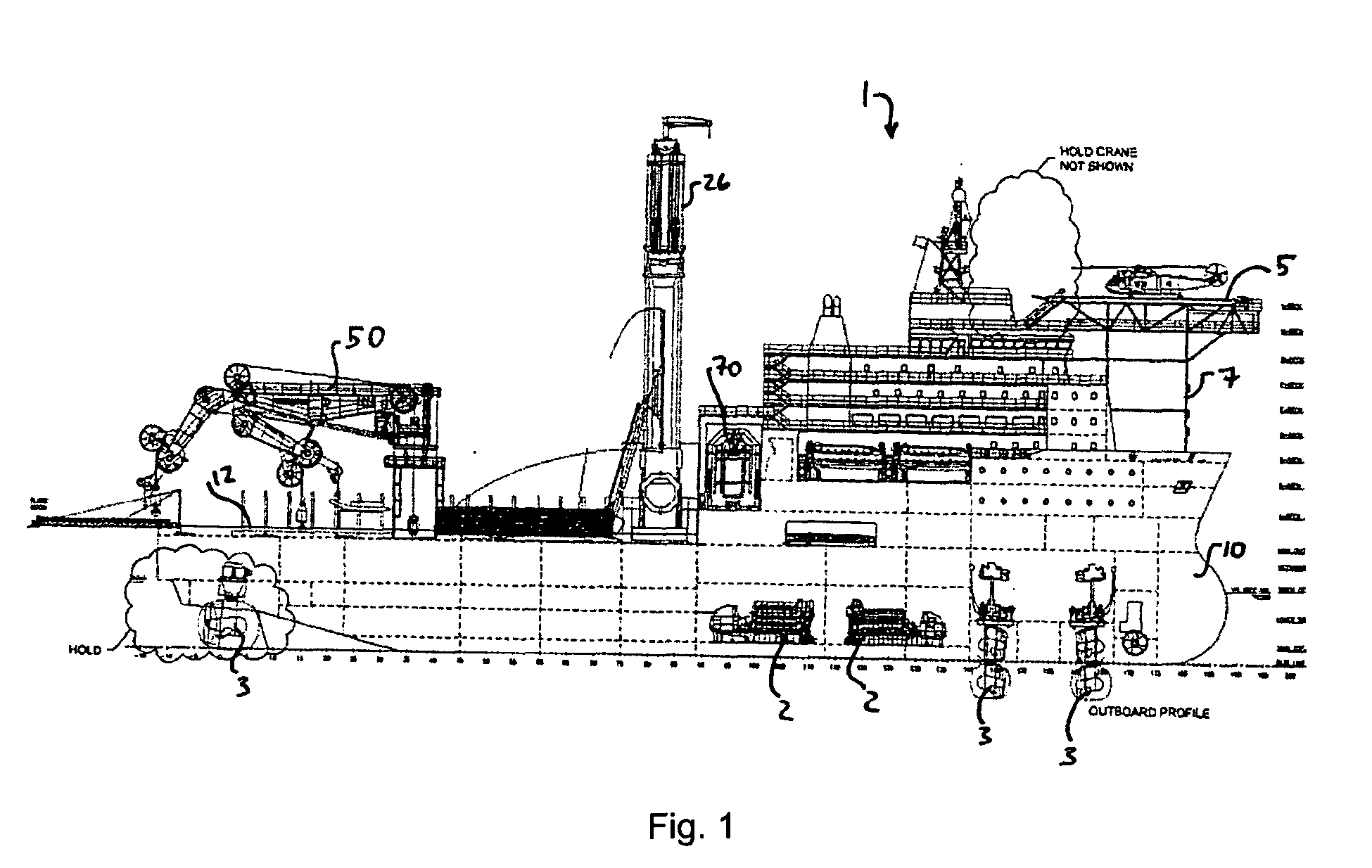

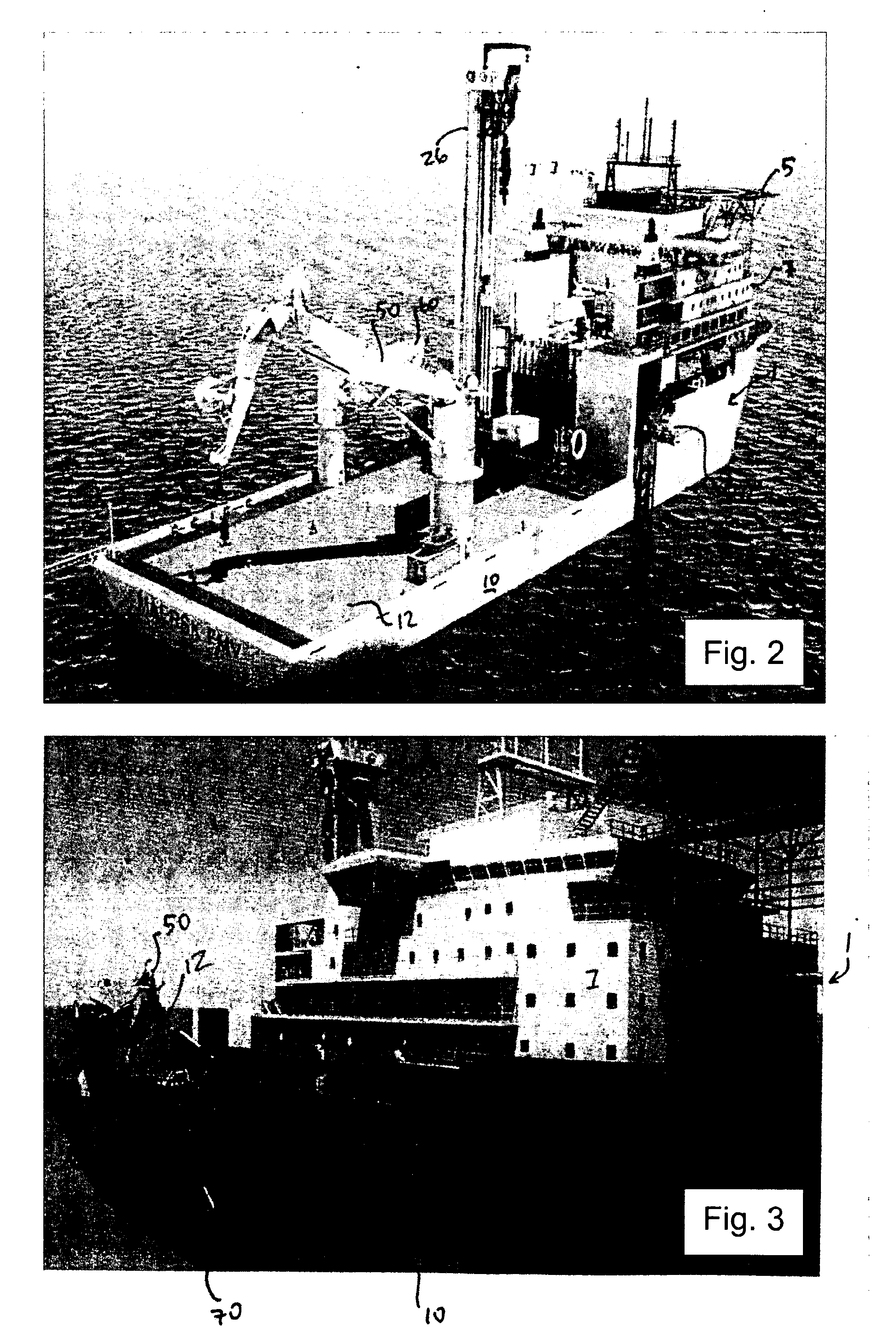

[0034]As shown in FIGS. 1-6, the drill ship 1 includes a hull 10, crew quarters structure at section 7, a helipad 5 and a main deck 12. Positioned on the aft region of the deck 12 are the box tower hoisting and lowering system and top drive 26, a heavy-lift knuckle-boom seafloor active heave crane 50, a medium duty seafloor and deck crane 60, and an ROV installation with an integrated vessel control center 70.

[0035]As shown in FIG. 1, directional thrusters 3 are positioned at various points in the hull, and the engines and power systems are housed within the hull as shown at 2. 4 azimuthing & 1 tunnel variable frequency thrusters are used. (20.3 MW combined thrusters rating), and capability to allow for loss of 1 Thruster in a Worst Case Compartment or Component Failure Mode which complies with requirements for redundant dynamic positioning capability.

[0036]The main hull 10 of the drill ship 1 is shown in the drawings at FIGS. 1-6. The hull 10 is formed for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com