Multi inductively coupled plasma reactor and method thereof

a plasma reactor and inductive coupling technology, applied in the direction of electrical discharge tubes, decorative surface effects, electrical apparatus, etc., can solve the problems of contaminated interior of the reactor, non-uniform plasma density, deformation or damage of the electrode, etc., and achieve the effect of enhancing process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]To fully understand many objects to be accomplished by various embodiments and operational advantages of this invention, preferred embodiments of this invention will be described in a more detailed manner with reference to the attached drawings. In the attached drawings, like elements will be referred to as like numerals. Furthermore, the detailed technical explanation of already known functions and constructions will be omitted herein to avoid a faint determination of the subject matter of this invention.

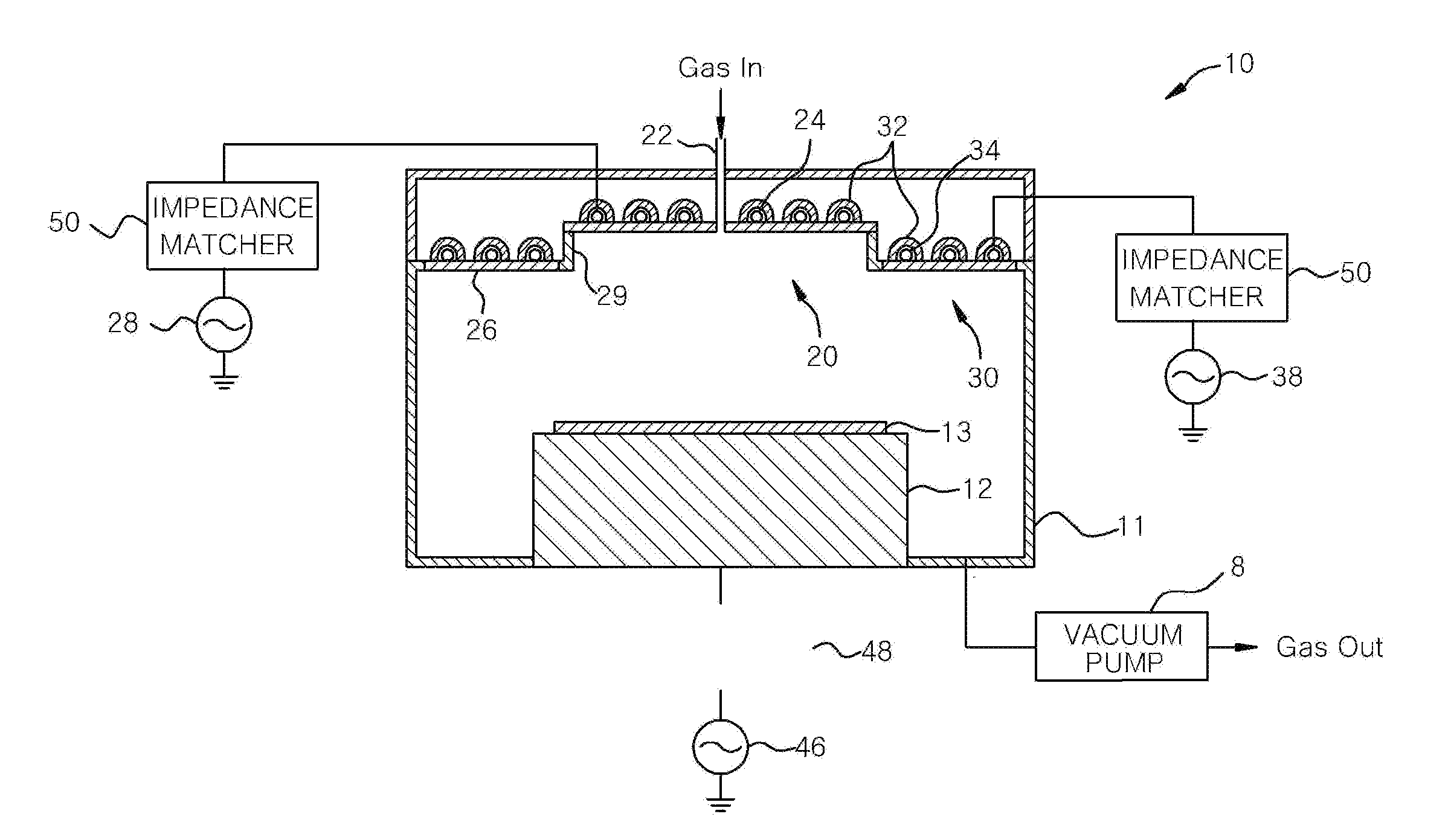

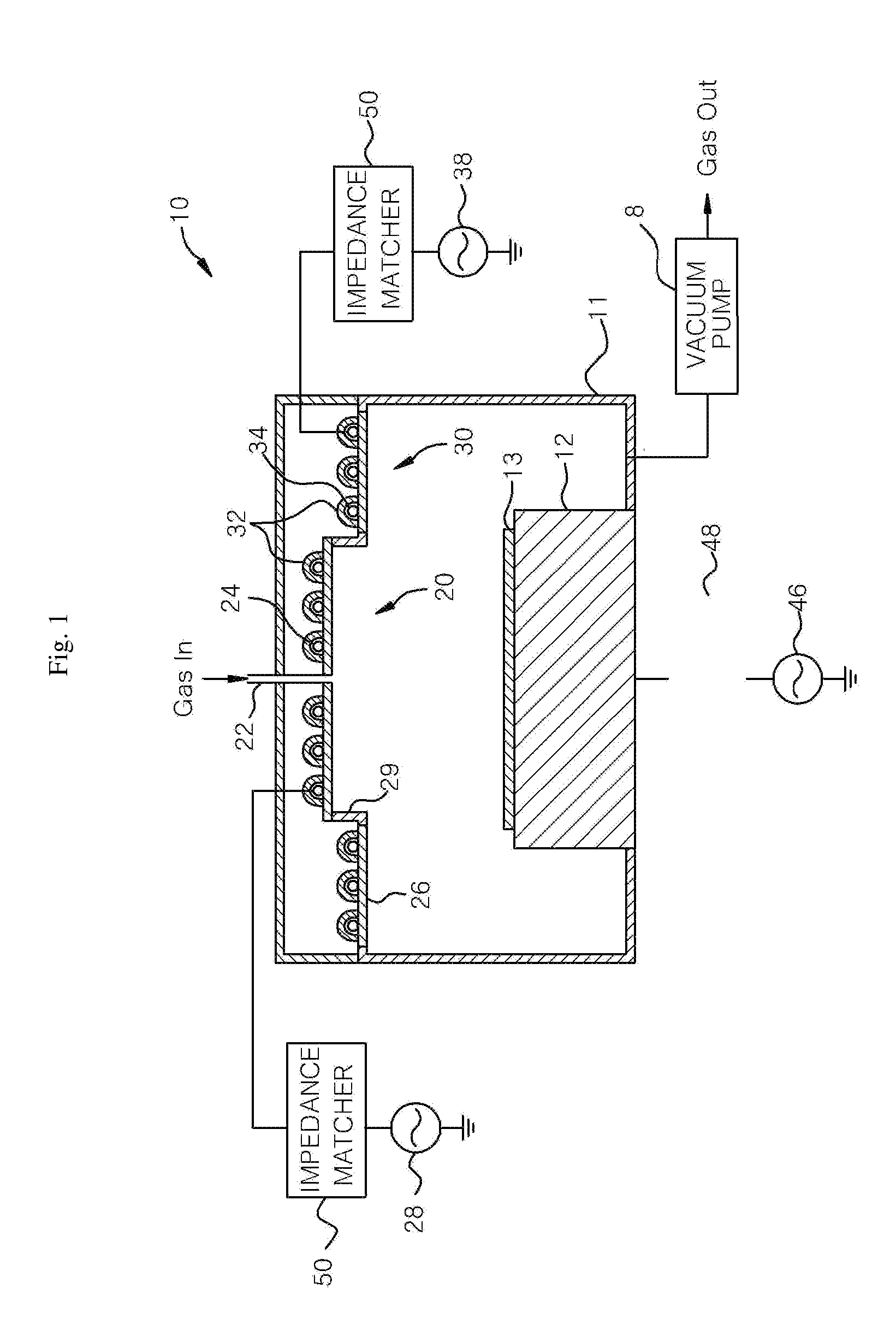

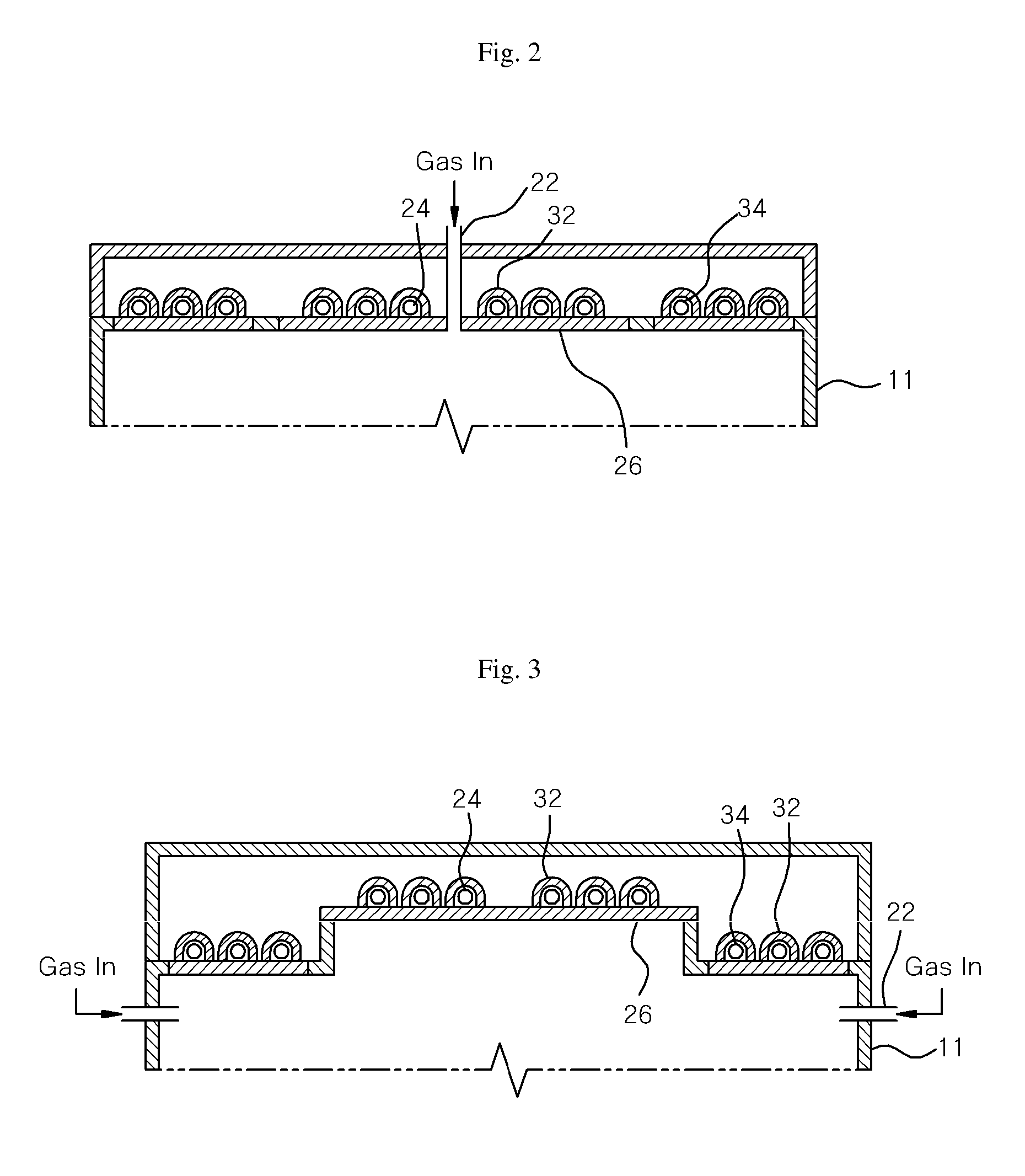

[0050]FIG. 1 is a sectional view showing a plasma process apparatus in which a central plasma source and a peripheral plasma source are separated each other according to a preferred embodiment of the invention.

[0051]Referring to FIG. 1, a multi-inductively coupled plasma reactor 10 according to a preferred embodiment of the invention is constructed of a reactor body 11, a central plasma source 20 and a peripheral plasma source 30. The reactor body 11 internally has a substrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com