Insulated structure including cavities holding aerogel connected to a vacuum sustaining unit

a technology of aerogel and sustaining unit, which is applied in the field of thermal insulation systems, can solve the problems of vacuum loss, reliability of such structures, brittleness and relatively low strength of glass materials generally used, etc., and achieve the effects of preventing heat loss to the atmosphere, significant effect on the overall efficiency of solar heat collectors, and without substantial heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

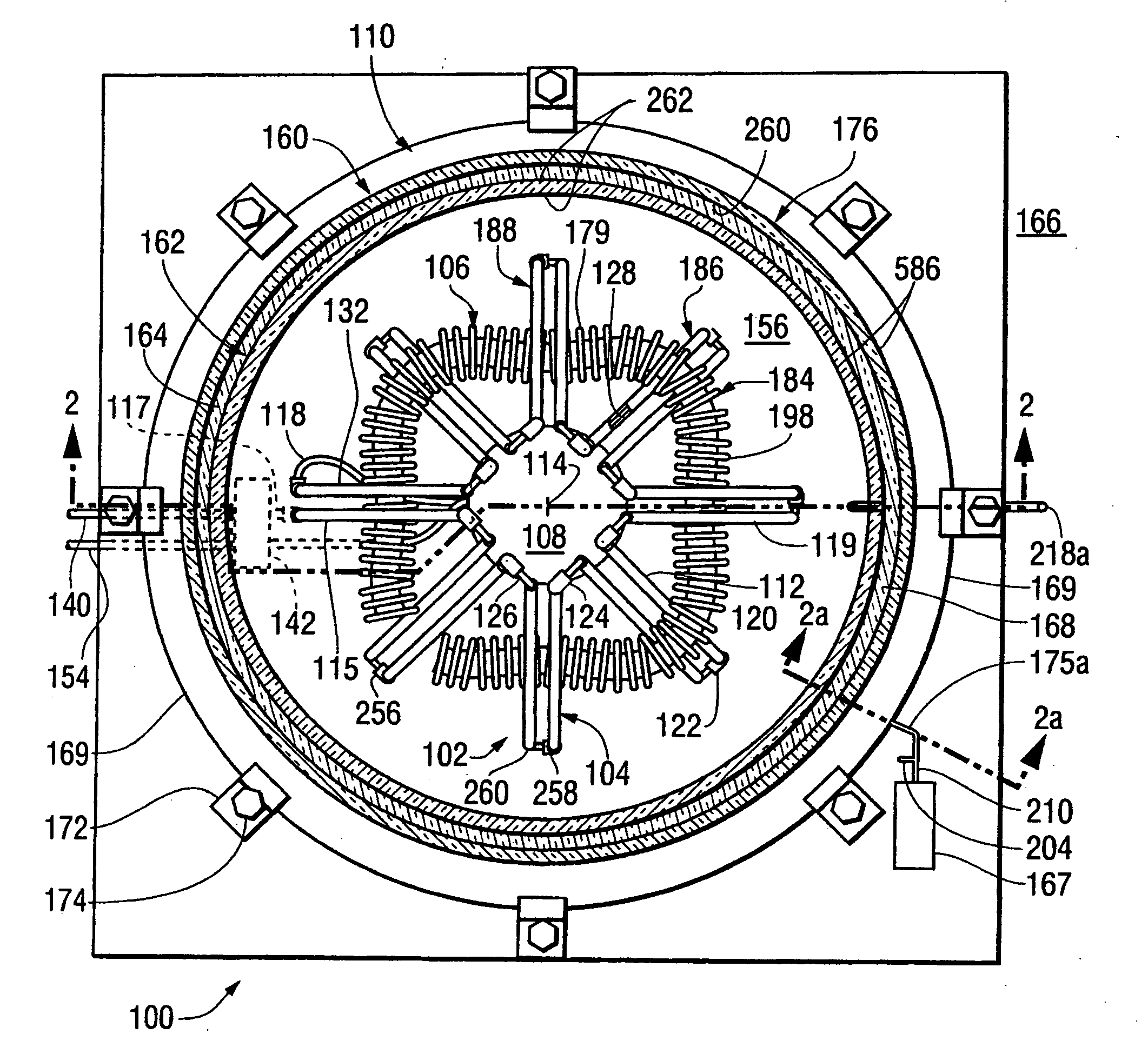

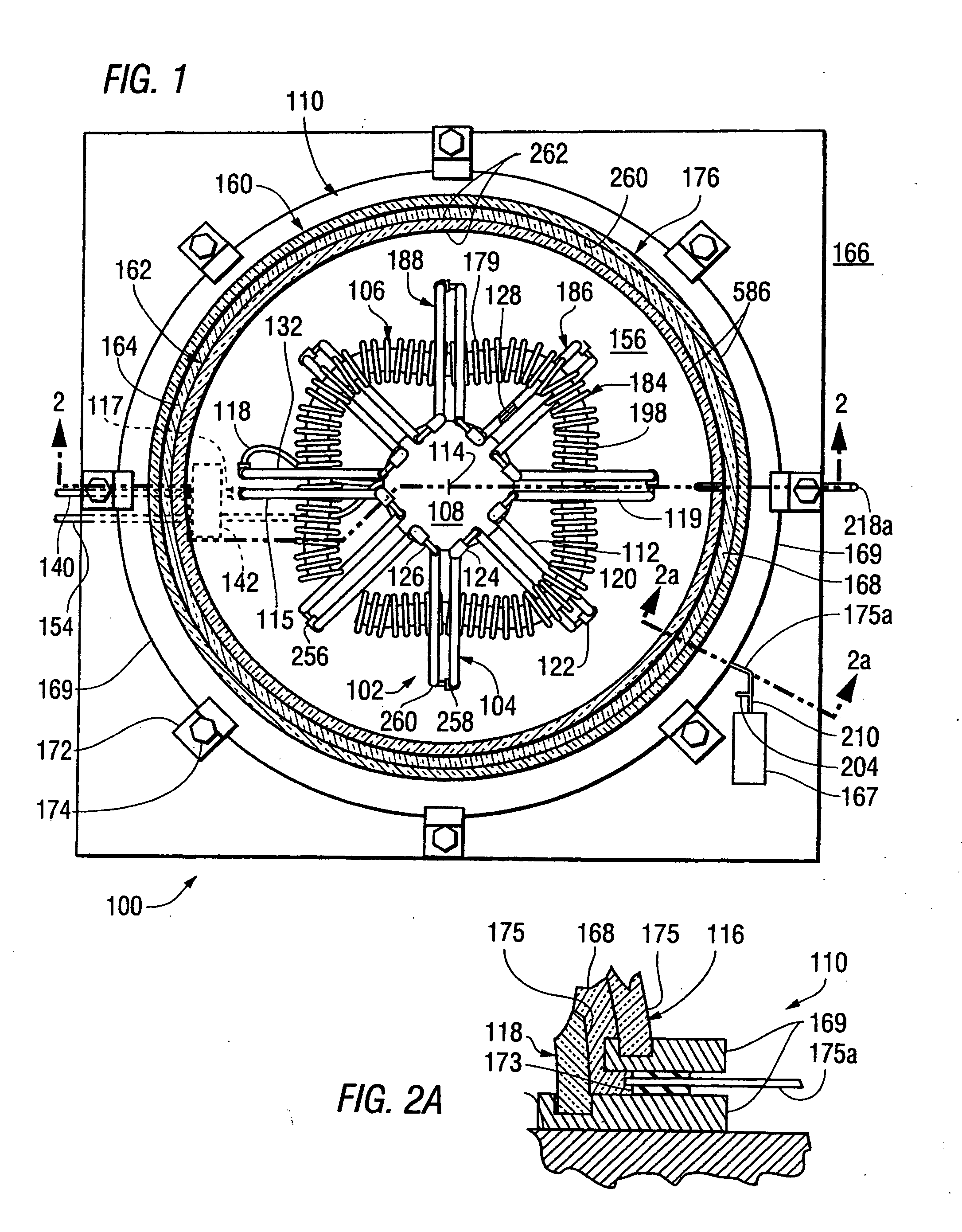

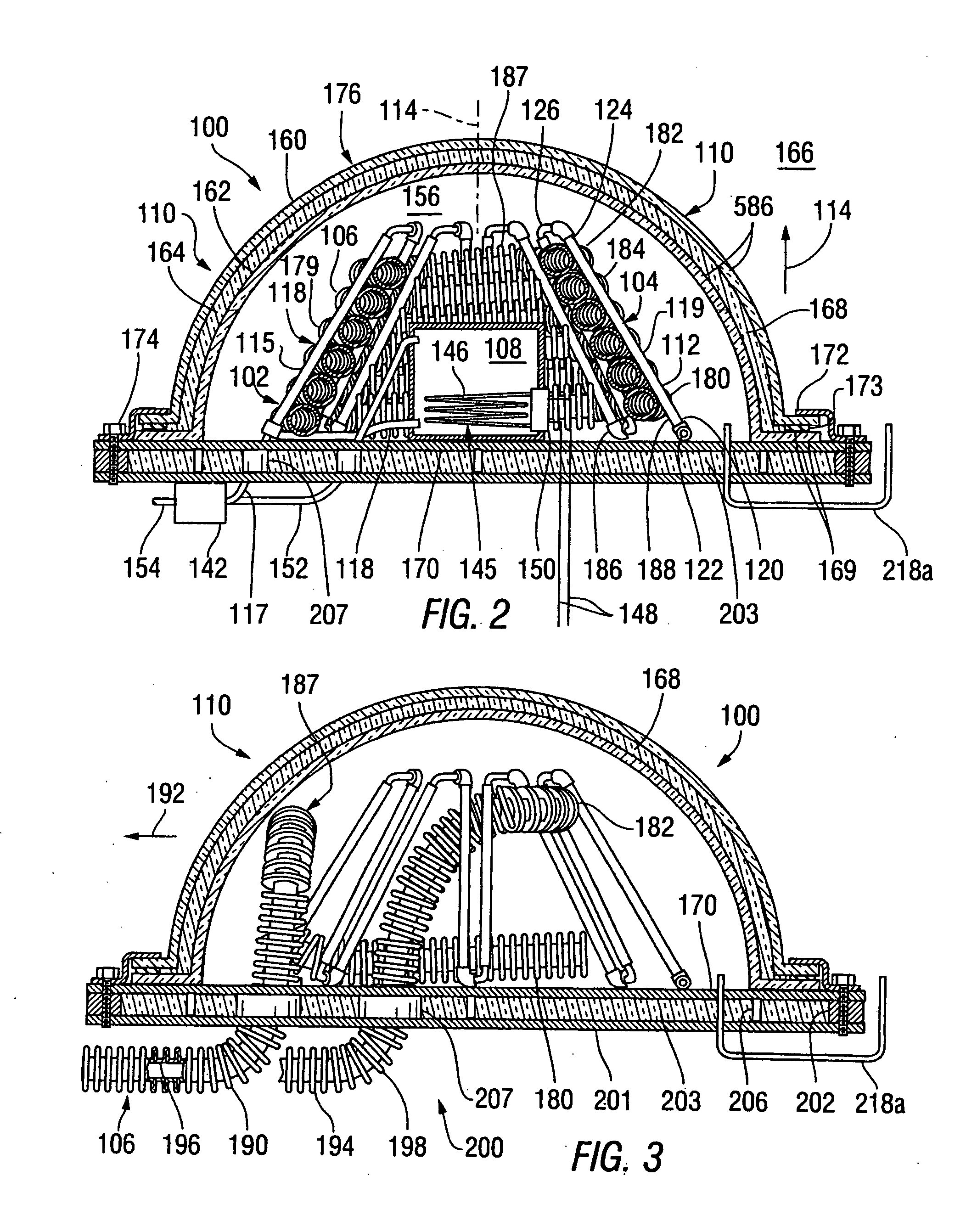

[0066]A solar heat collector having a dome-shaped structure built in accordance with the present invention will first be discussed with reference being made to FIGS. 1-7. FIG. 1 is a plan view of the solar heat collector 100, while FIG. 2 is a cross-sectional elevation thereof, taken as indicated by section lines 2-2 in FIG. 1. The solar heat collector 100 includes a frame 102 having a plurality of legs 104, a transverse hose 106 winding around the frame 102 and between the legs 104, and a reservoir 108, all held within a translucent dome structure 110.

[0067]Within the frame 102, each of the legs 104 includes a pair of tubes 112, disposed in a circular pattern 113 around a central axis 114 of the hybrid solar heat collector 100 and extending upward, in the direction of arrow 116 and inward, toward the central axis 114. The legs 104 include an inlet / outlet leg 115, in which the tubes 112 are connected to an inlet tube 117 and an intermediate tube 118, and a number of interconnected l...

second embodiment

[0083]A solar heat collector having a dome-shaped structure built in accordance with the invention will now be discussed, with reference being made to FIGS. 8-24. FIG. 8 is a perspective view of an alternative dome-shaped structure 300 extending around and over a dome-shaped solar heat collector 302, which is, for example, built as described above in reference to FIG. 5. Alternately, the dome shaped structure 300 may, for example, enclose a dome-shaped solar heat collector built as described above 1-3 and 7. The dome-shaped structure 300 includes a frame 320 having frame members 322 including horizontal frame members 324 and vertically extending frame members 326, intersecting with one another to form a plurality of frame openings 327. The dome-shaped structure 300 additionally includes base members 328 attached to the lowermost horizontal frame members 324 and to a floor structure (not shown). Fluid paths 332 into the solar heat collector 302 extend outwardly through the base membe...

third embodiment

[0109]In accordance with the invention, a thermally insulating system is provided, including at least one cavity connected to a vacuum sustaining unit and filled with an aerogel. Examples of such insulating systems will now be discussed, with reference being made to FIGS. 27-36.

[0110]FIG. 27 is a cross-sectional end elevation of a thermally insulating panel 610 built for use within a thermally insulating structure built in accordance with a third embodiment of the invention to include a plurality of such insulating panels 610 attached to a vacuum sustaining unit 167, as described above in reference to FIG. 4A. The insulating panel 610 includes a pair of side panels 612 held in a spaced-apart condition within a frame 614. An evacuation tube 616 extends through the frame to provide for the evacuation of air from the interior space 618 between the side panels 612, and seals 620 prevent, or at least minimize, the return of air into the interior space 618 following evacuation. In the exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com