Pump

a technology for pumping and nozzles, applied in the field of pumps, can solve the problems of limited rotation of the whole air output piping, difficulty in connecting the nozzle, and the large volume of the floor pump, and achieve the effect of increasing the overall length of the air output piping of the pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

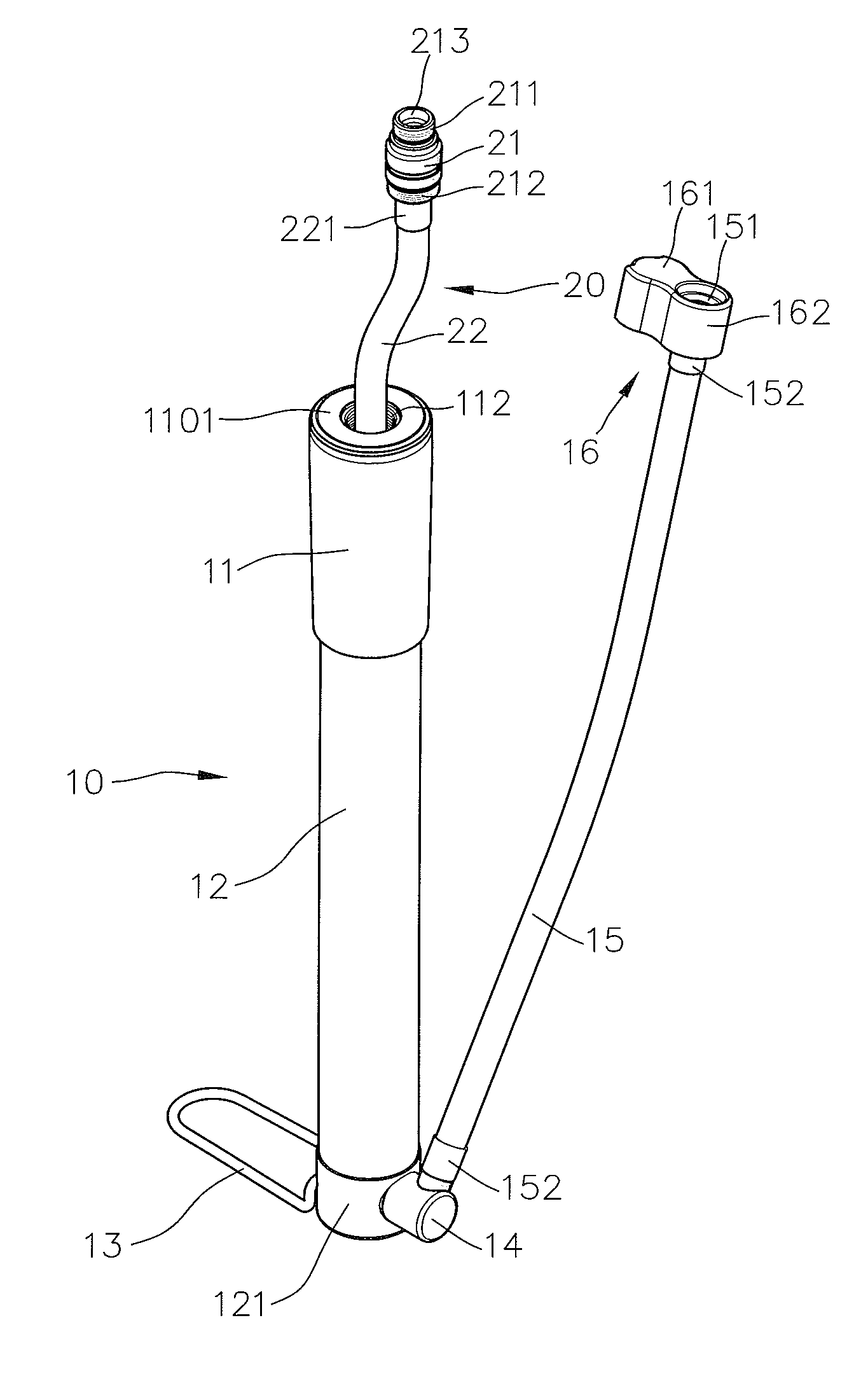

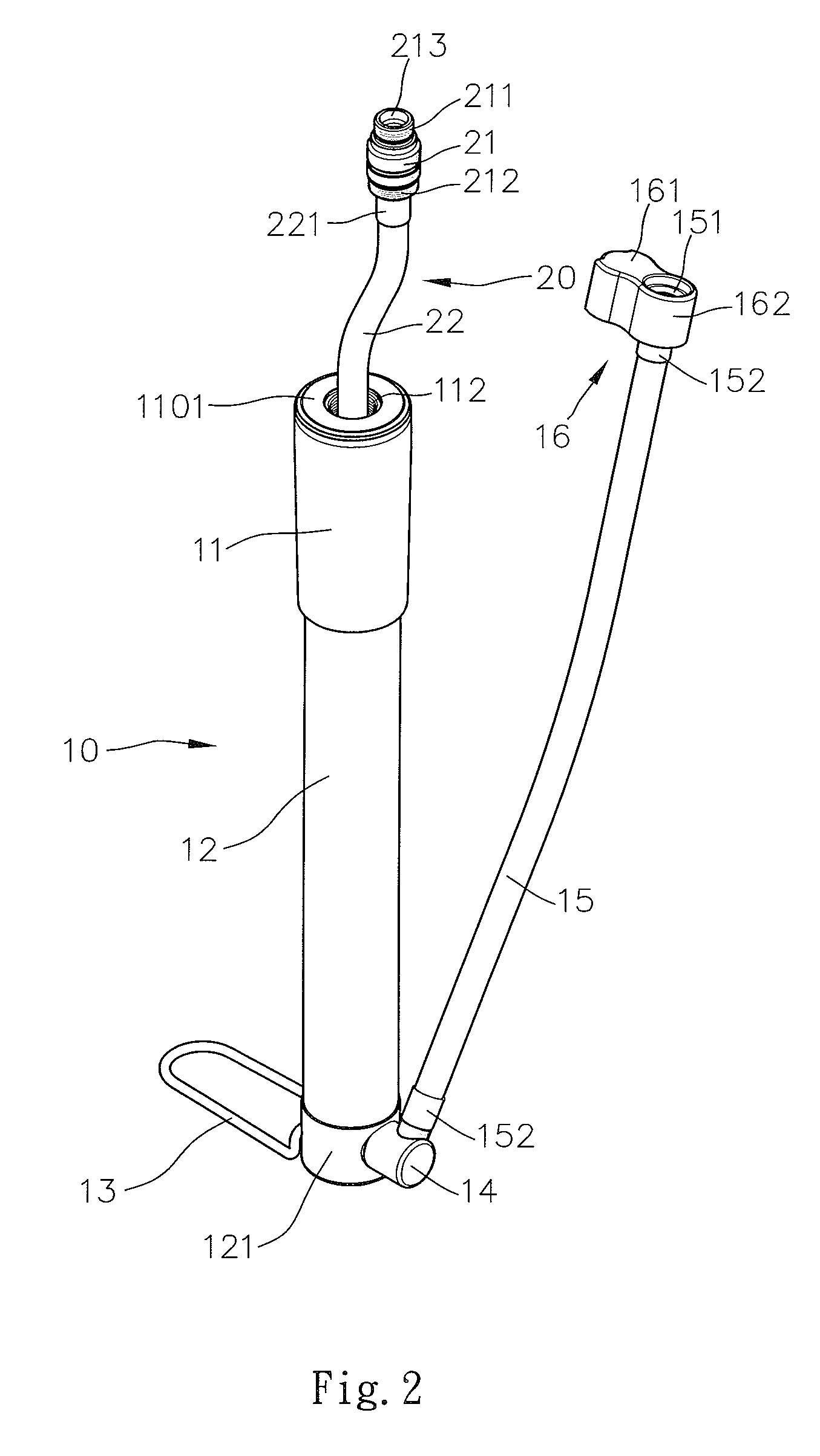

[0015]FIGS. 2-4 show a preferred embodiment of a pump 10 according to the present invention. The pump 10 includes a barrel 12 in the form of a hollow cylinder. A piston rod 111 is slideably received in the barrel 12. A handle 11 is attached to an upper end of the piston rod 111. Compared to conventional mini floor pumps, the piston rod 111 of the present invention includes a hollow receiving portion 1111. In this embodiment, an end portion 1101 in the form of a hollow cylinder is threadedly engaged to the handle 11, and the handle / end portion 1101 is then threadedly engaged with the top end of the piston rod 111. The end portion 1101 includes an inner periphery having a positioning portion 112 with an inner thread. The top end of the piston rod 111 is threadedly engaged with a bottom end of the positioning portion 112. A ring 123 is mounted around the outer periphery of the piston rod 111 at a connection area between the end portion 1101 and the receiving portion 1111. The ring 123 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com