Lubricating System for a Two-Stroke Engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

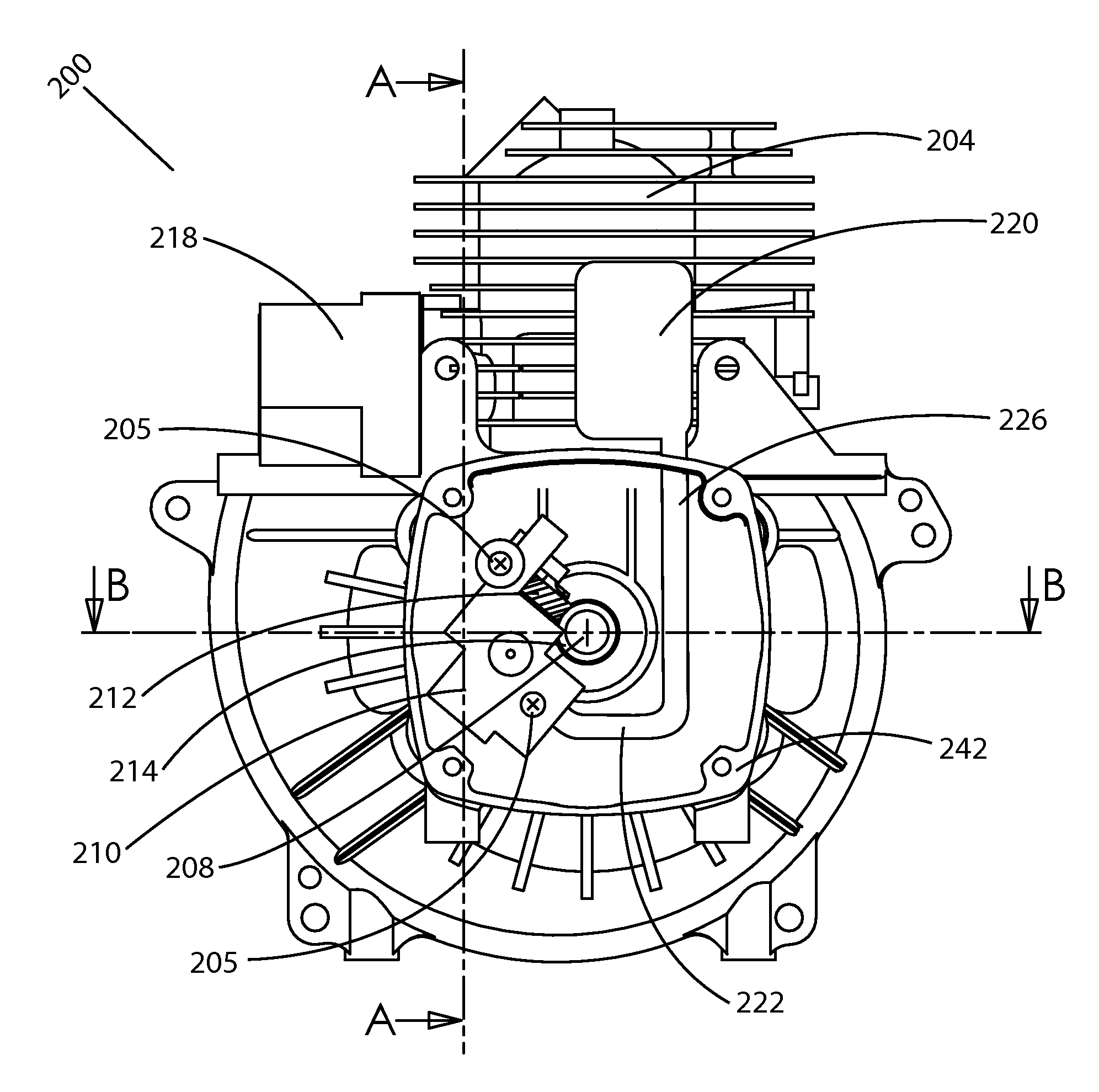

[0020]FIG. 1 is an embodiment of the present invention. FIG. 1 shows an oil injected two-stroke engine 200 having an oil tank 220, and an oil pump 210 mounted on to the side of the crankcase 242 by screws. The pump 210 has a gear 212 and is driven by the crankshaft 208 having a gear 214. The gears 212 and 214 can be of pinion and worm type or any other type. The two-stroke engine 200 can be a liquid or gaseous fueled engine. The engine 200 has a cylinder 204, crankshaft 208, and intake manifold 218. The rest of the parts necessary for operation of the two-stroke engine, such as piston, connecting rod, muffler, fuel metering device, etc are very much similar to any two-stroke engine and can be constructed by anyone skilled in the art. The oil supply line 226 from the oil reservoir 220 feeds into the oil pump 210. The oil pump 210 may have an oil return line, not shown here, to return excess oil back into the oil reservoir 220.

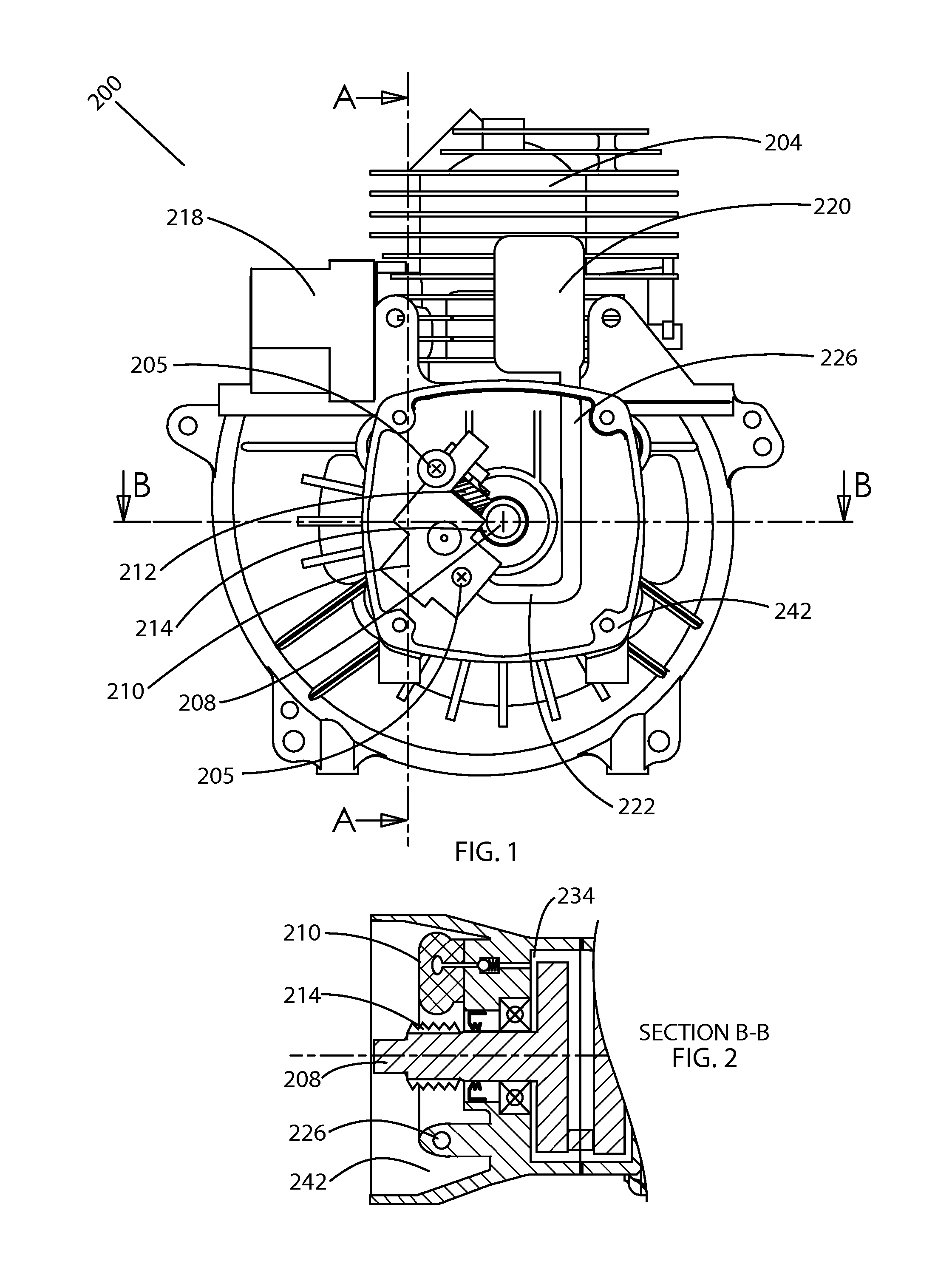

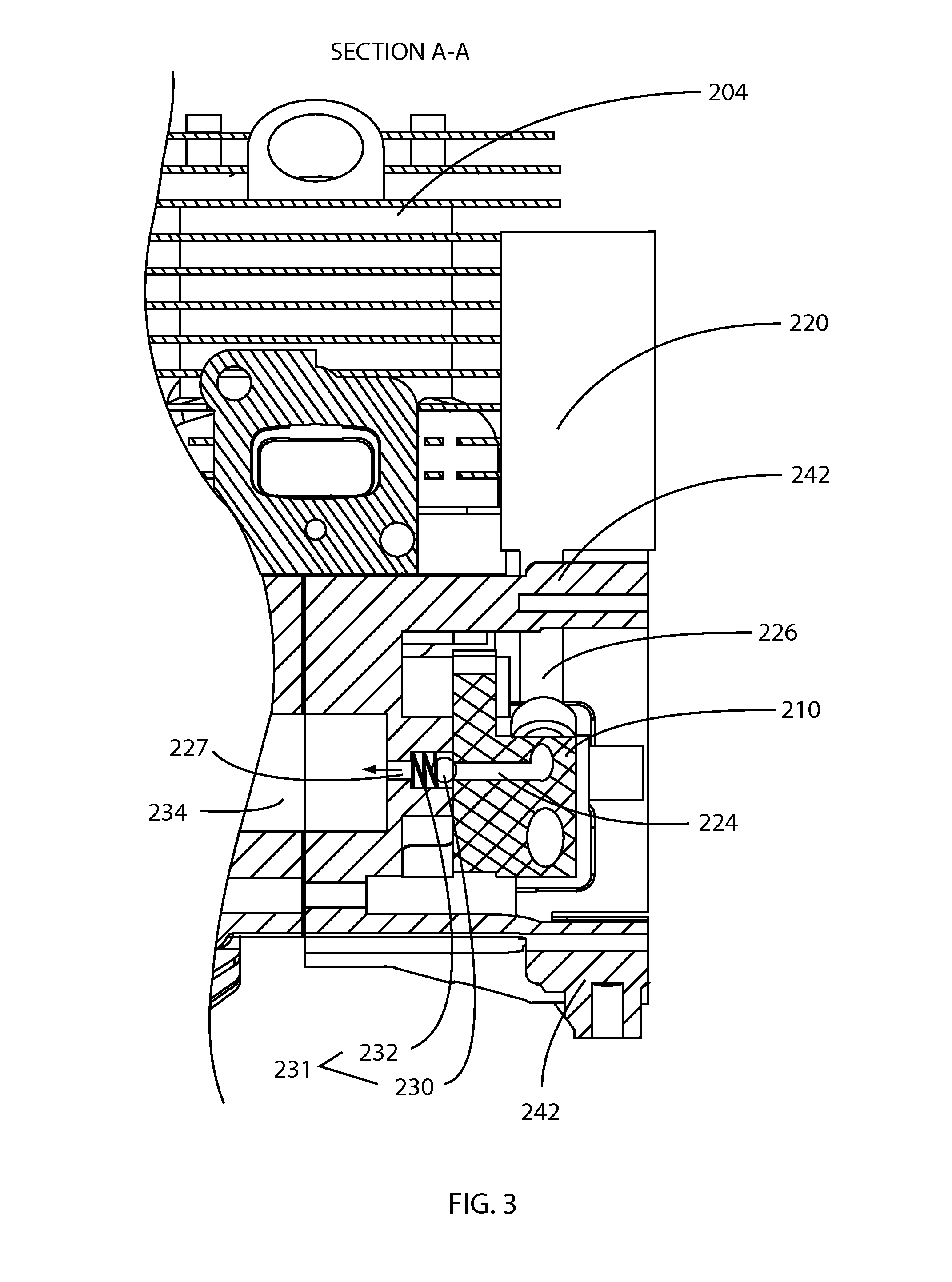

[0021]FIG. 2 shows the partial top sectional view of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com