Method for producing a flexible circuit configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

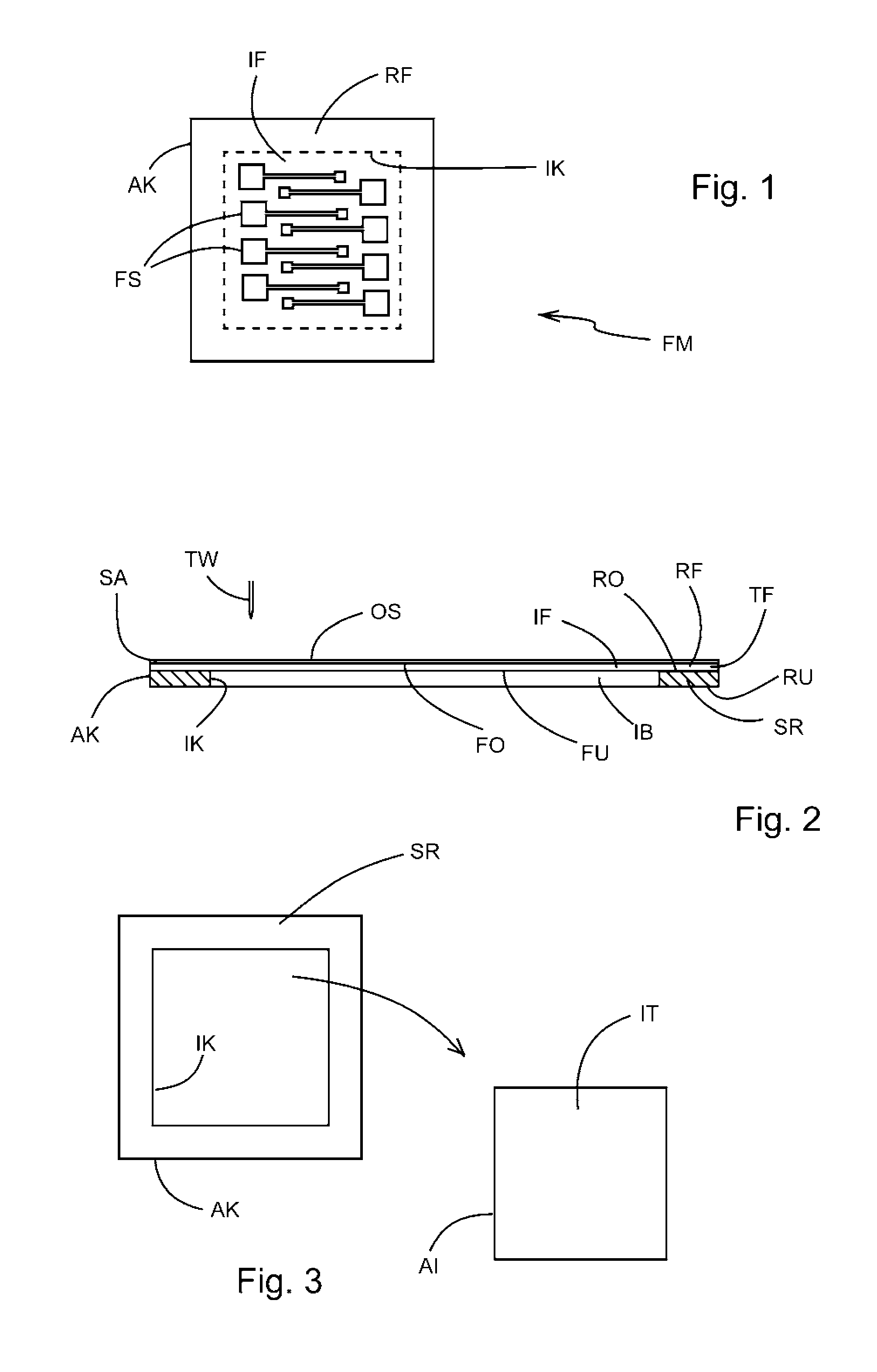

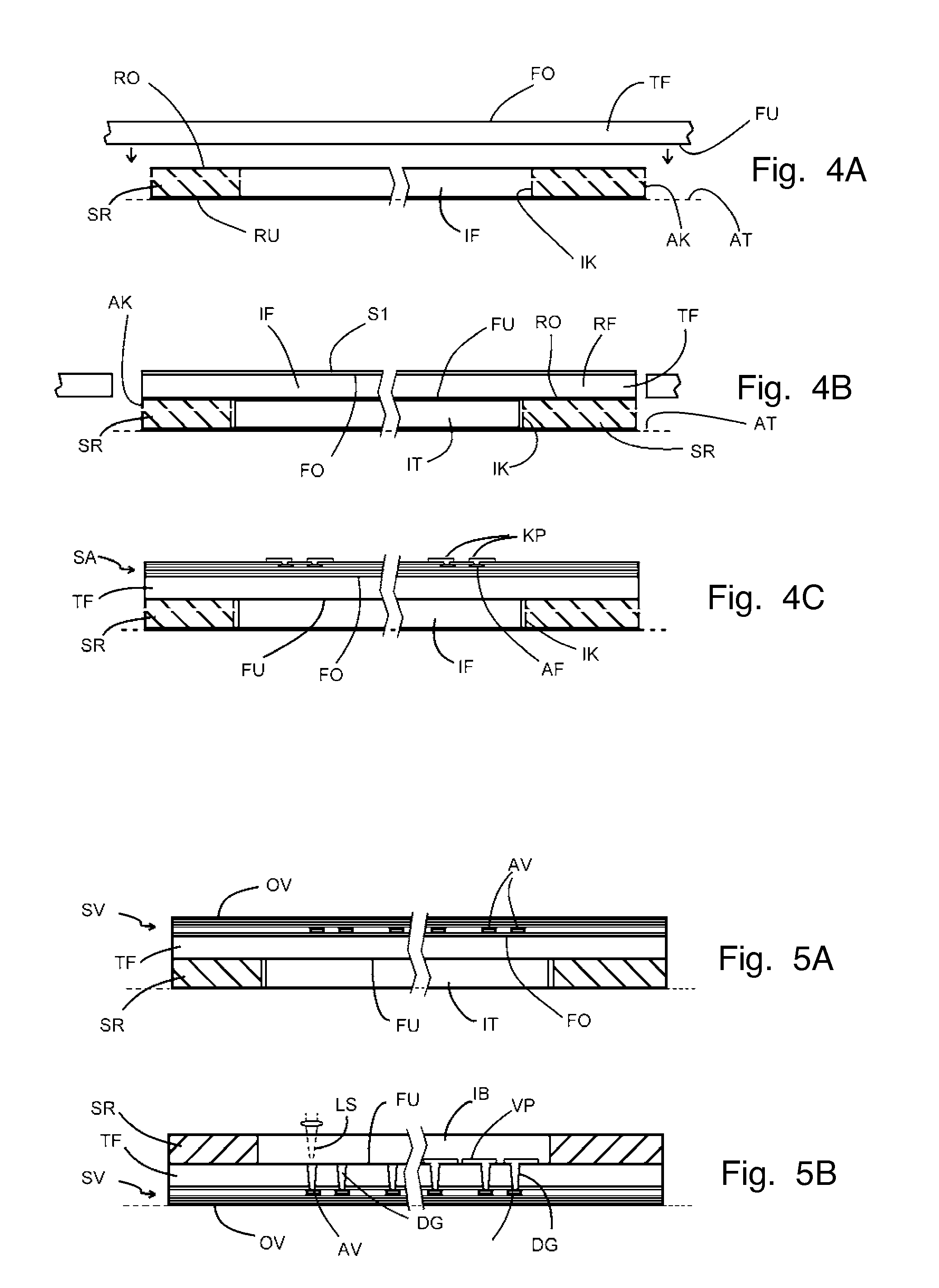

[0023]In the examples described hereafter, the relative dimensions of the individual components in the drawings are not shown to scale. In particular, the thickness of the film and the thickness of the layer structure or individual layers of the layer structure are shown greatly exaggerated.

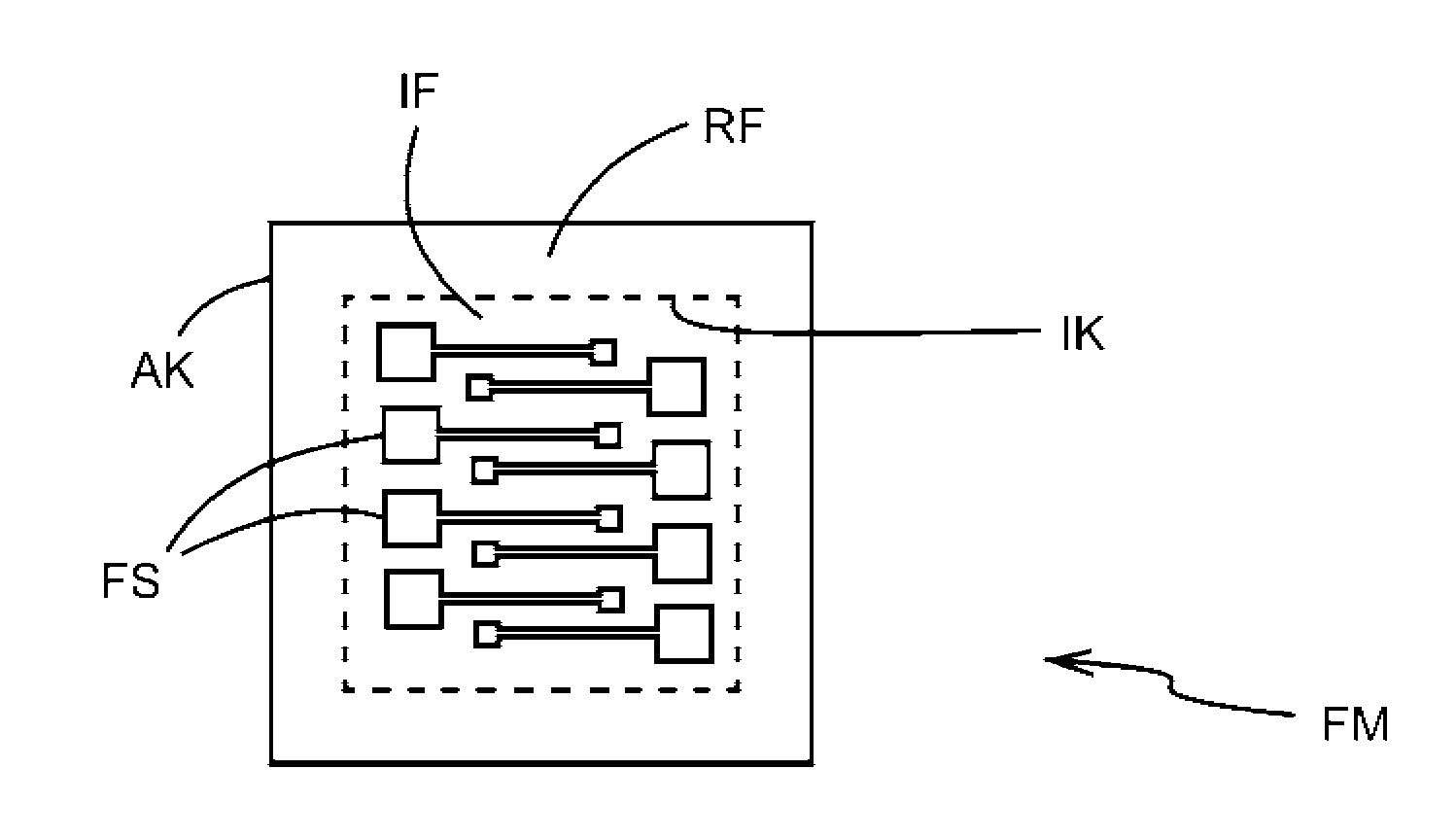

[0024]FIG. 1 shows a manufacturing module FM in a view perpendicular to the surface of a layer structure for flexible circuits. Multiple flexible circuits FS are indicated by their contours. In FIG. 2, a sectional side view of FIG. 1 is shown in a different scale. FIG. 3 shows a preferred production of a rigid frame SR, which is used in the method or the manufacturing module, in which a cutout is produced from a closed plate surface along an inner contour IK. During the production of the cutout, an inner part IT arises as the cutout plate section, whose outline Al is less by the cutting width of the cutout than the inner contour IT of the rigid frame SR. The inner part IT can therefore be laid un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com