Aircraft including an undercarriage motor

a technology of undercarriage motor and aircraft, which is applied in the field of aircraft, can solve the problems so as to achieve the effect of increasing the weight of the aircra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

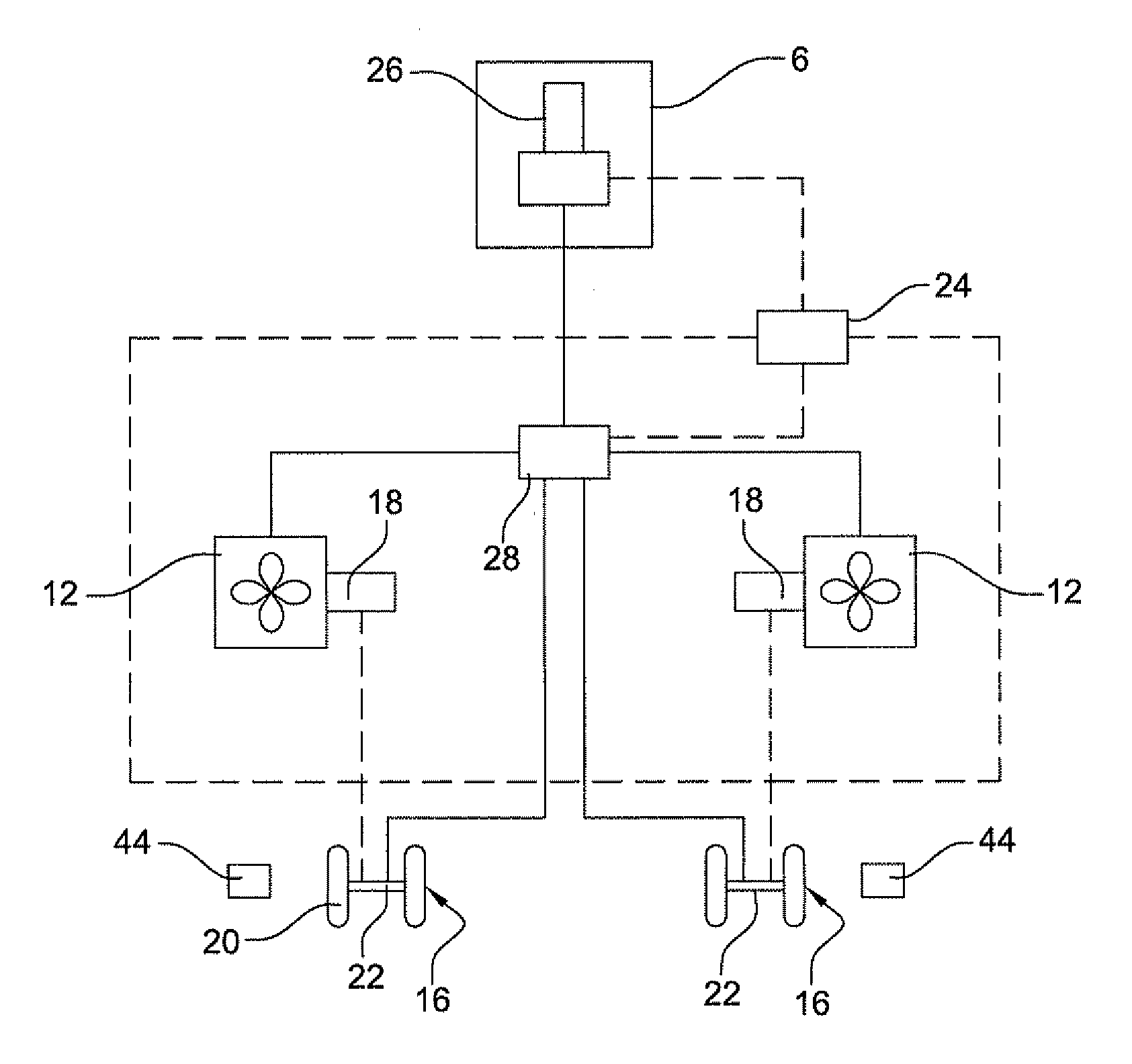

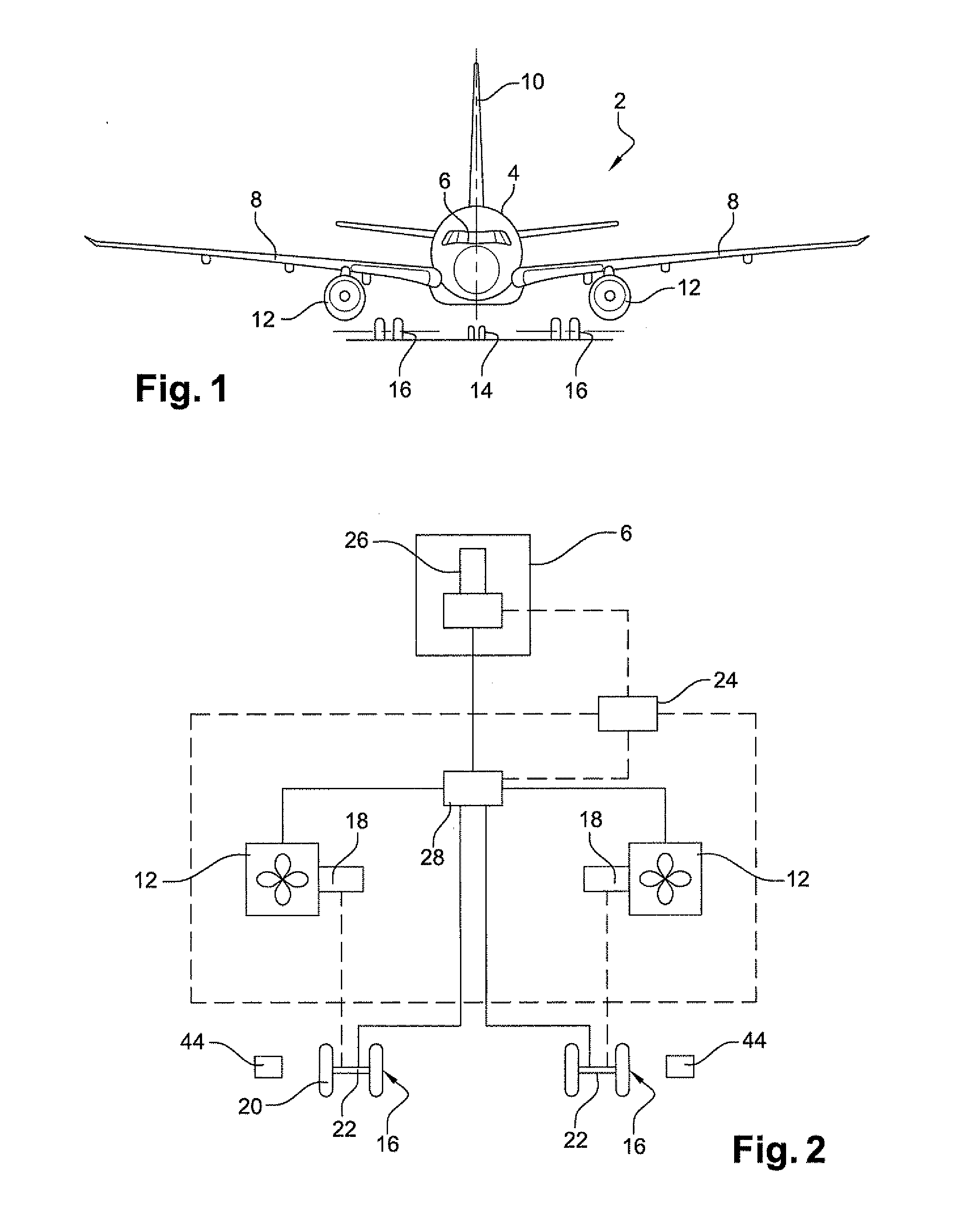

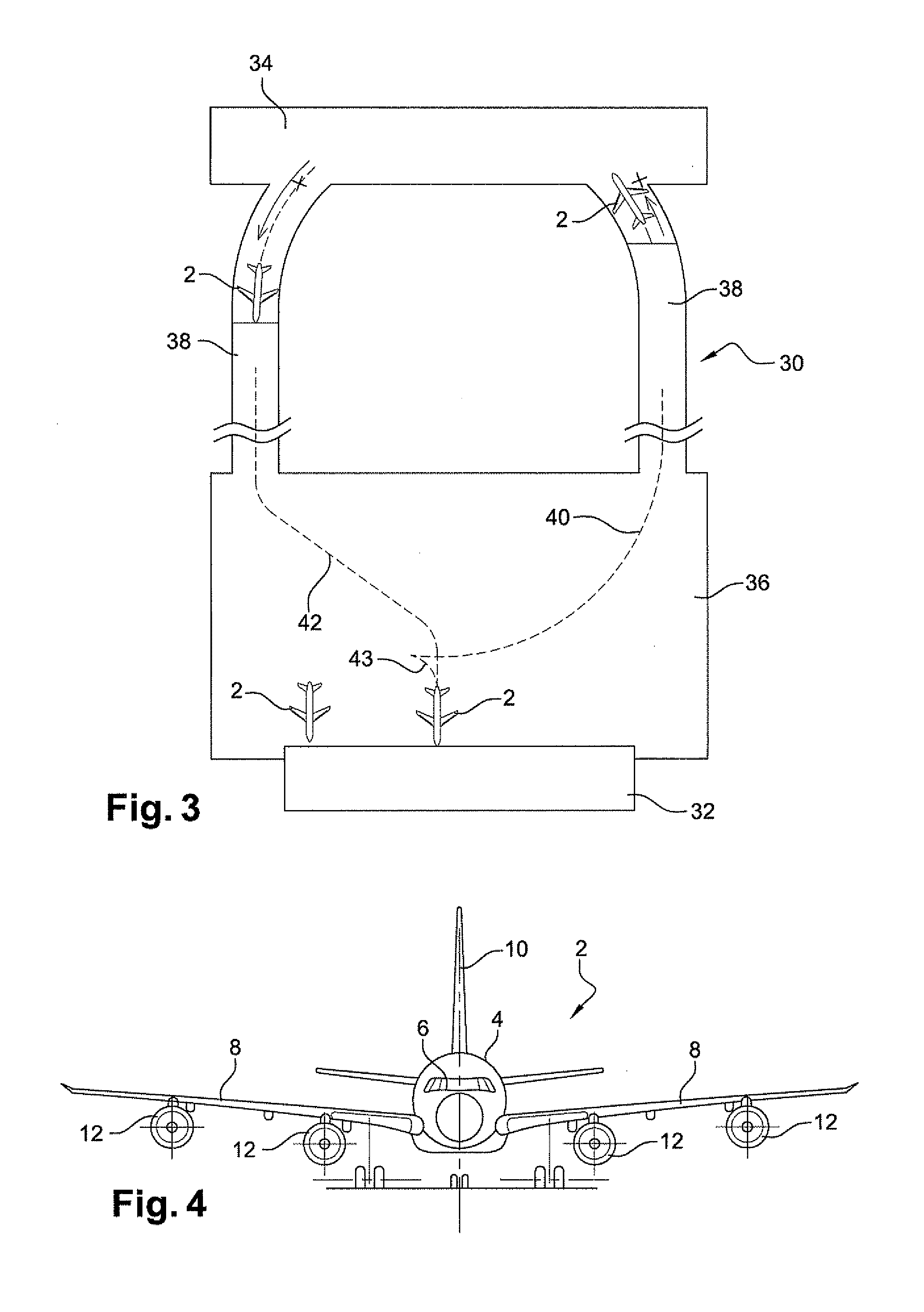

[0045]A first embodiment of an aircraft 2 of the invention is shown in FIGS. 1 and 2.

[0046]In this example the aircraft 2 is an aerodyne, and specifically an airplane. More specifically it is a commercial airliner for transporting freight and / or passengers. It is suitable for receiving at least one person. It has a fuselage 4 with a cockpit 6 of the airplane at the front thereof. It has two wings 8 extending on either side of the fuselage together with a tail fin 10. The airplane 2 has two engines 12 carried by respective ones of the wings 8 for propelling the airplane in flight. By way of example they may be turbojets or turboprops. The engines 12 operate by burning a fuel such as kerosene coming from tanks (not shown) of the airplane. Each engine 12 is associated with an electricity generator 18 having a rotary portion that is suitable for being driven by the engine in order to produce electricity.

[0047]The airplane has undercarriages comprising a nosewheel 14 situated under the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com