Real-time monitoring of retaining ring thickness and lifetime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

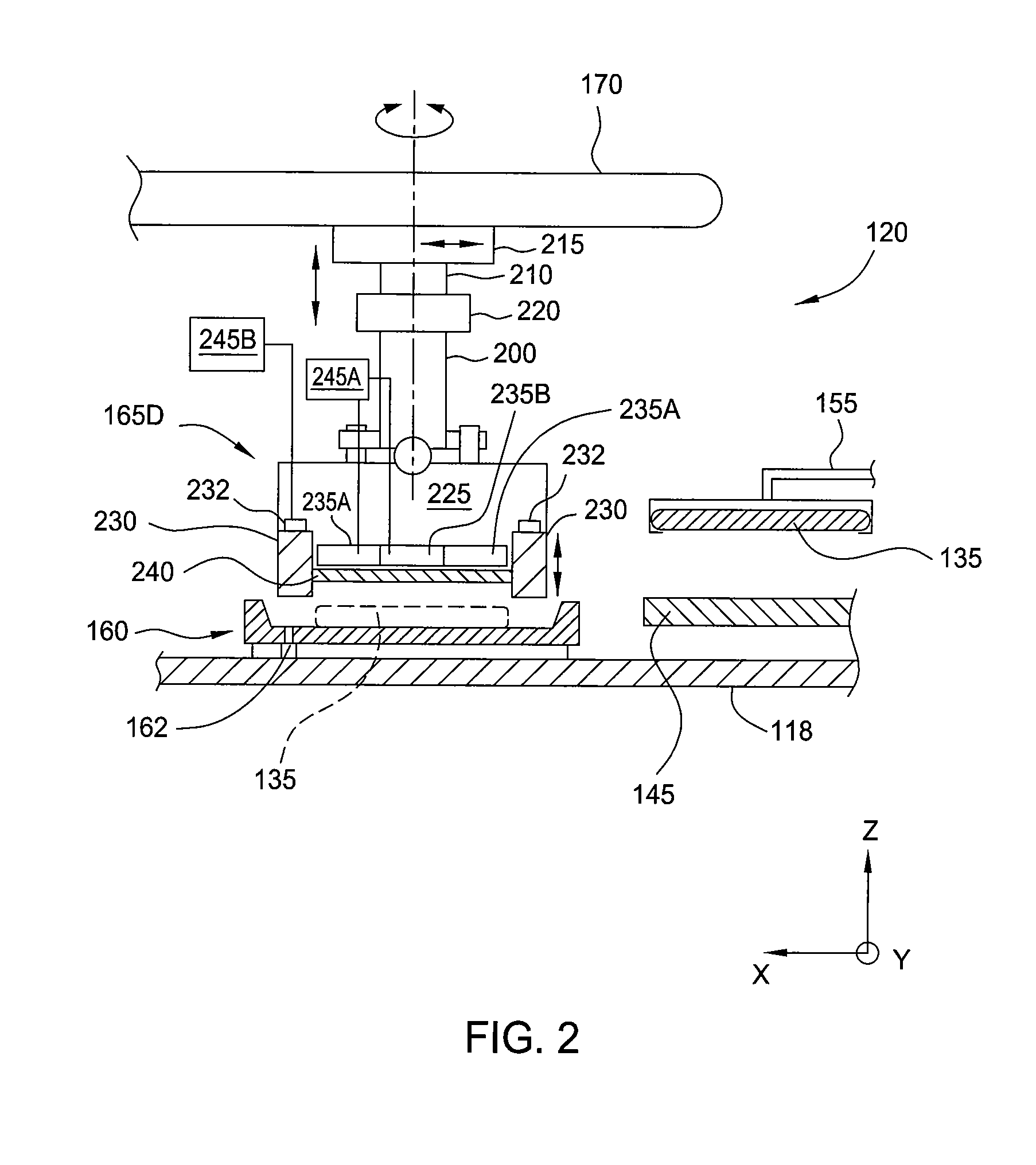

[0023]The invention generally provides a method and apparatus that facilitates monitoring of a retaining ring within a polishing system to determine wear of the retaining ring and / or assess lifetime of the retaining ring. An on-tool monitoring device is described that provides monitoring of the retaining ring without the need to physically handle the retaining ring or shut down the polishing system. Additionally, data from the monitoring device may be provided to a controller and utilized for tuning subsequent polishing processes.

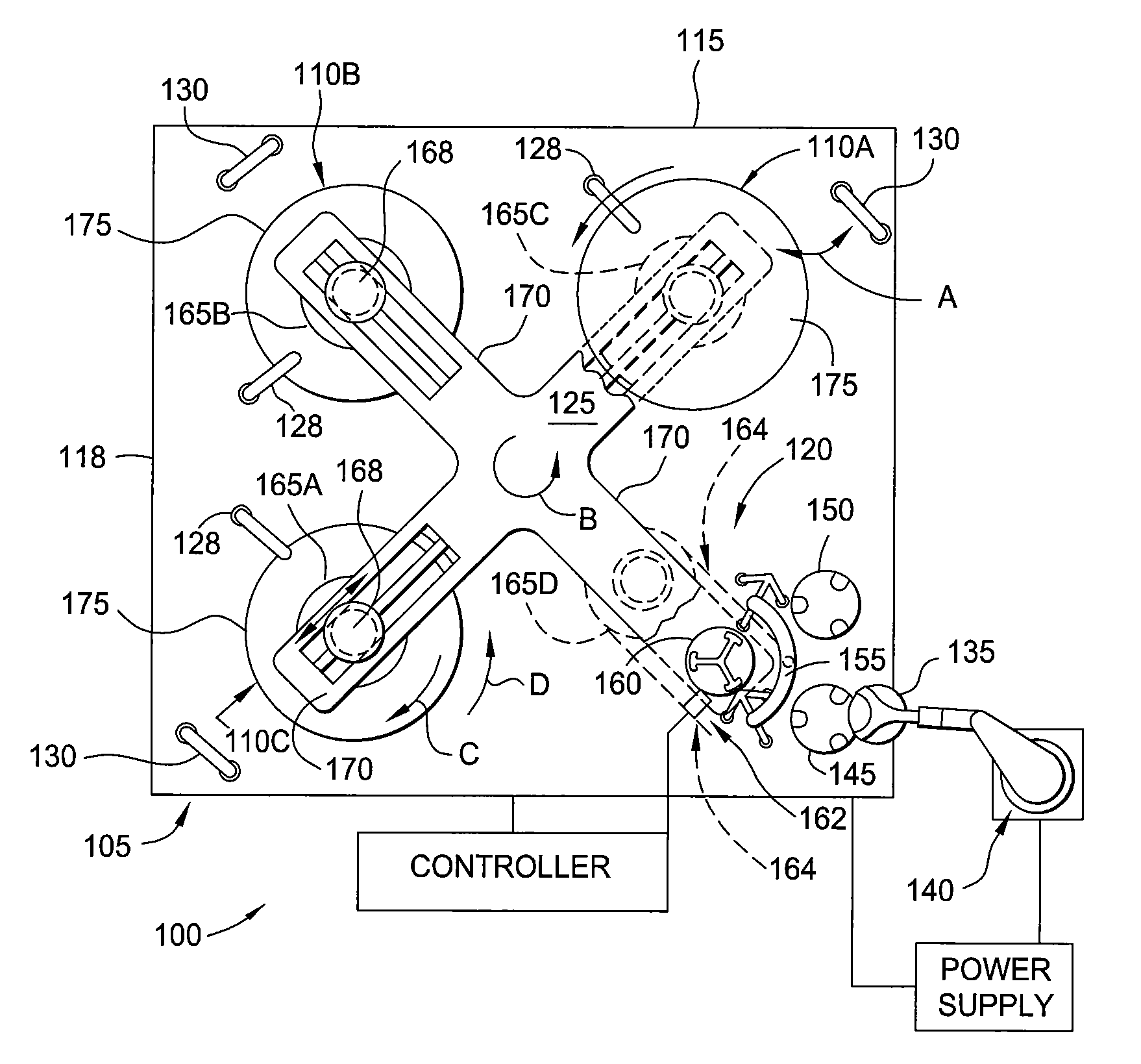

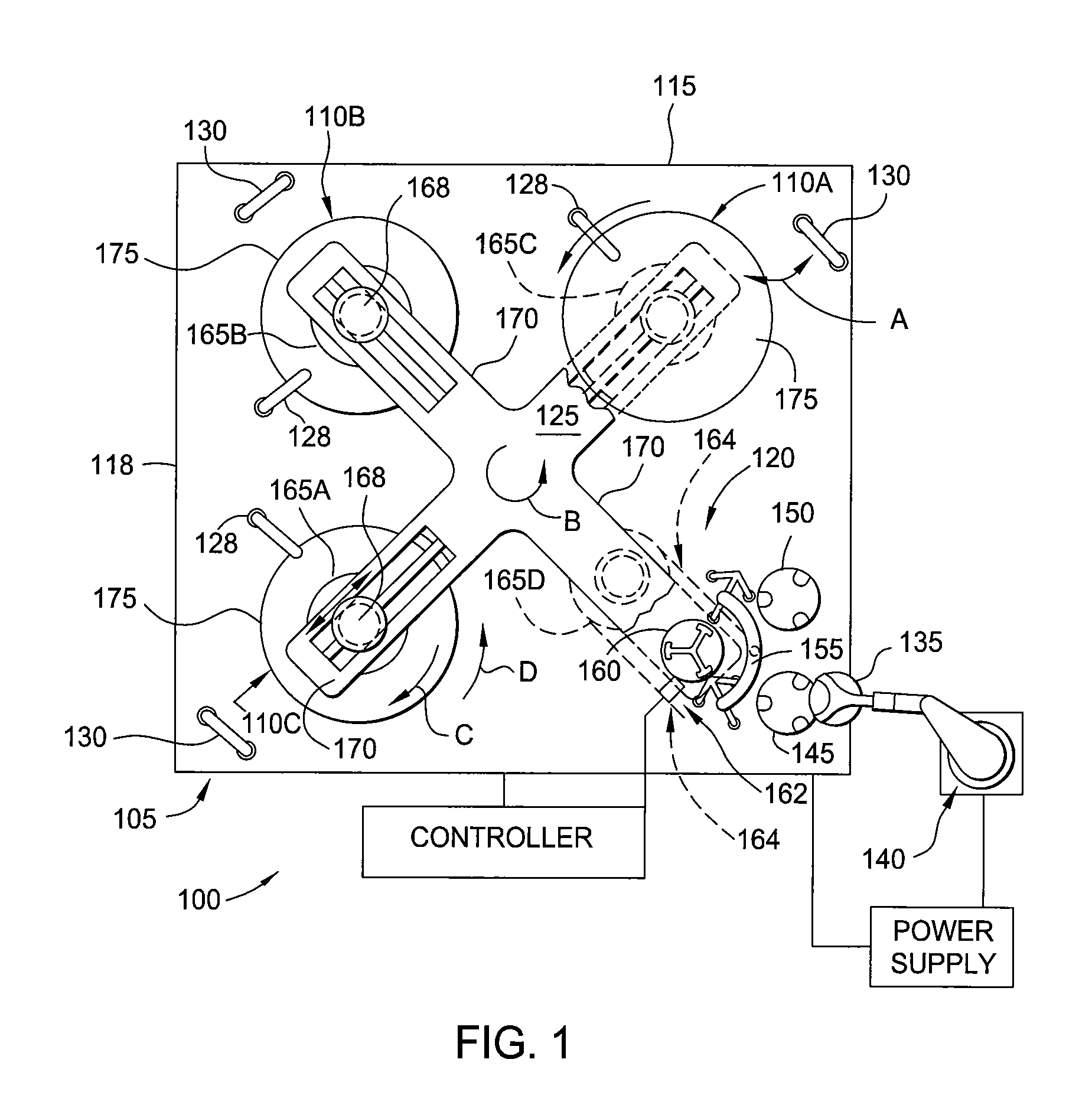

[0024]FIG. 1 is a plan view of a polishing system 100 having a polishing module 105 and a substrate transfer device that is suitable for electrochemical mechanical polishing and / or chemical mechanical polishing. The polishing module 105 includes a first polishing station 110A, a second polishing station 110B, and a third polishing station 110C disposed in an environmentally controlled enclosure 115. The substrate transfer device, such as a carousel 125, mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com