Container lid

a container and lid technology, applied in the field of container assembly, can solve the problems of many container lids, difficult removal, and jeopardizing the structural integrity of containers and lids, and achieve the effect of adding structural and operating advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

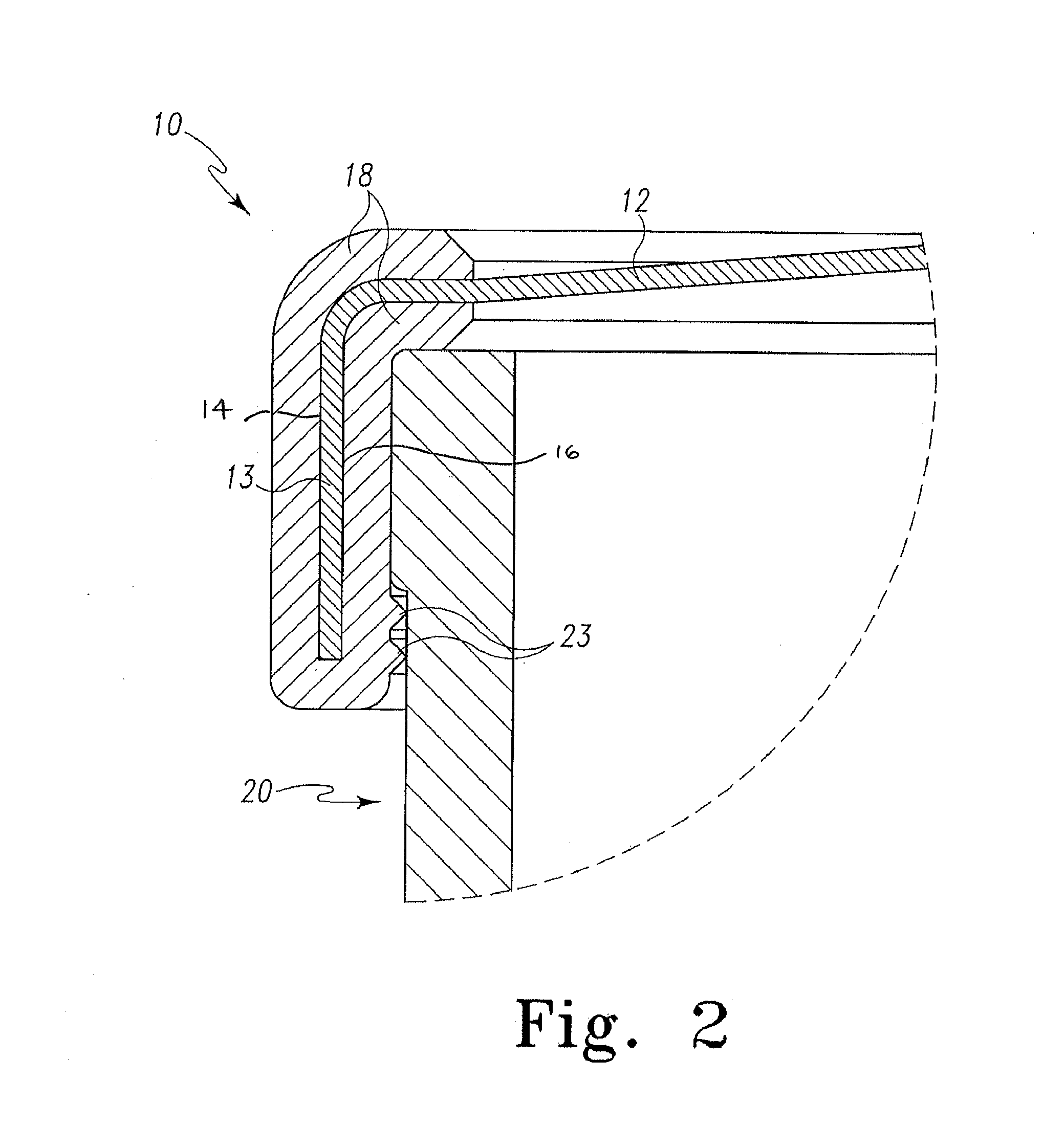

[0029]While this invention is susceptible of embodiments in many different forms, there is shown in the drawings and will herein be described in detail a preferred embodiment of the invention with the understanding that the present disclosure is to be considered as an exemplification of the principles of the invention and is not intended to limit the broad aspect of the invention to embodiments illustrated.

[0030]To the extent additional or alternative embodiments are disclosed herein, such additional or alternative components are consistently referenced using the same two digit number or, in some cases, by adding a leading third digit to the corresponding reference number. Otherwise, like components are consistently numbered in the following description and in each of the appended drawing figures.

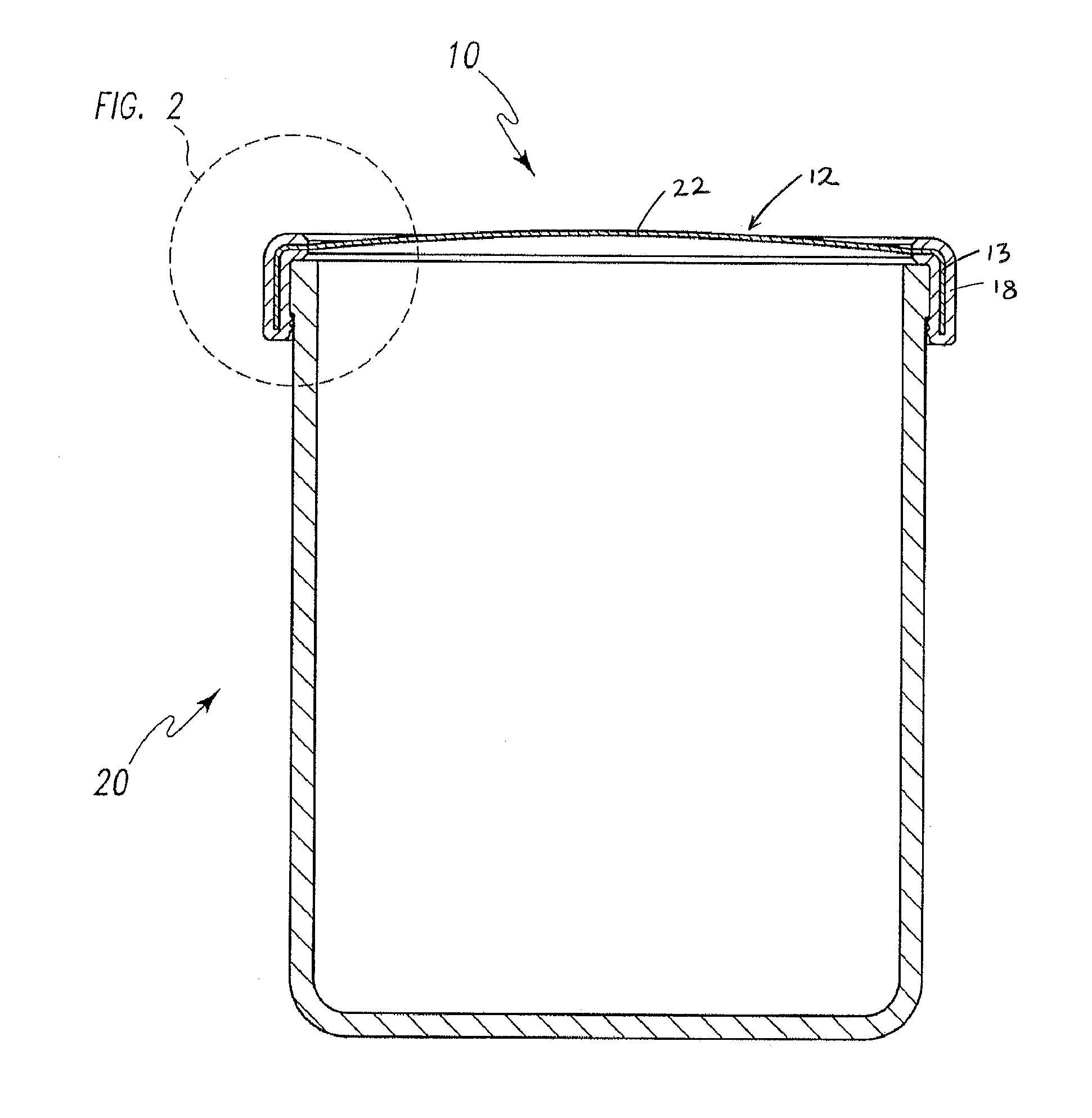

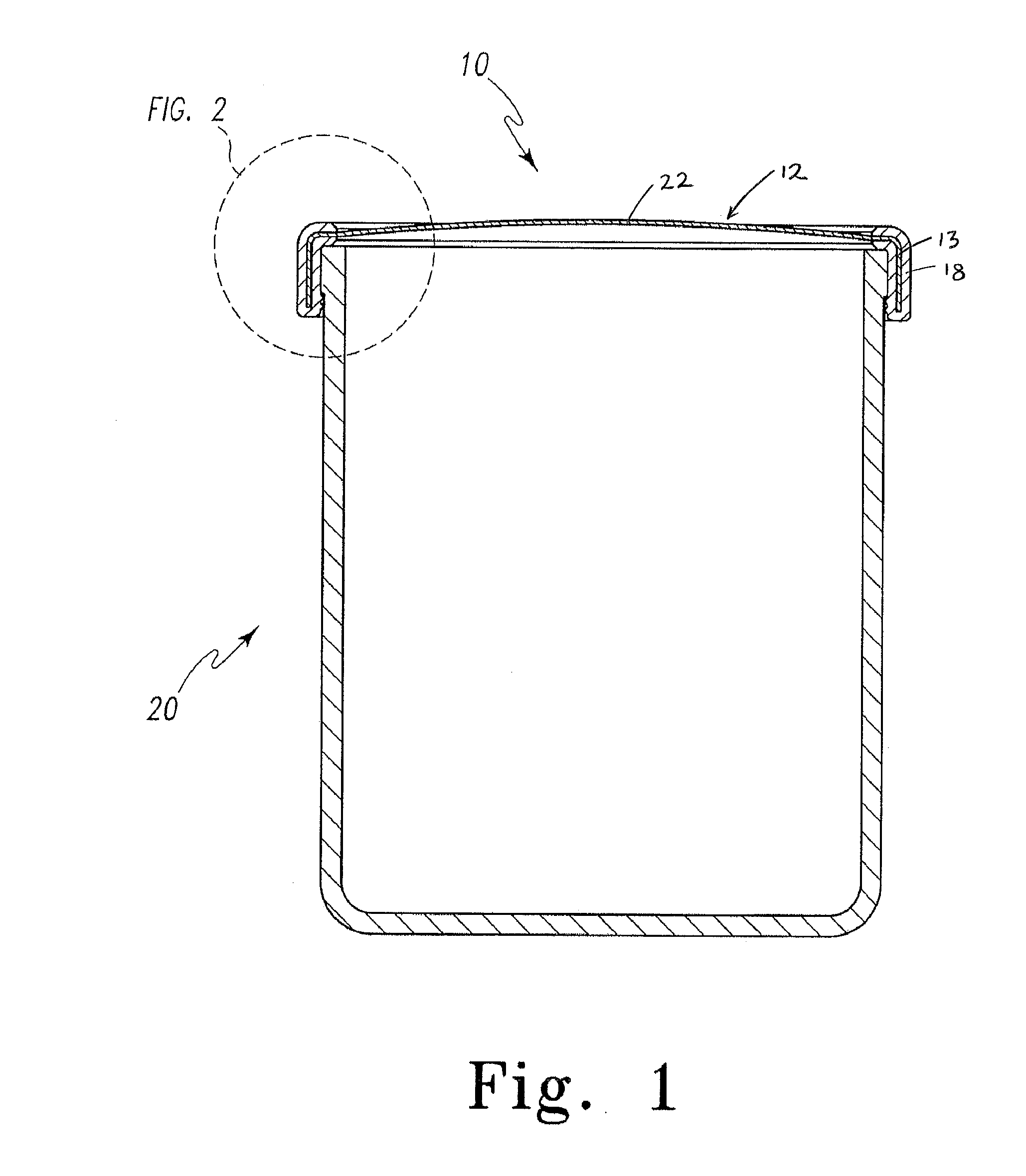

[0031]Referring to FIGS. 1-17, there is illustrated several embodiments of a container lid 10. Generally speaking, the container lid 10 is comprised of a thin, flexible, substrate 12 having...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexible | aaaaa | aaaaa |

| resilient | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com