Device for generating a cooling air flow in a preferential flow direction for cooling electrical components

a technology of electrical components and flow direction, which is applied in the direction of semiconductor devices for light sources, semiconductor/solid-state device details, lighting and heating apparatus, etc., can solve the problems of inability to prevent the risk of overheating of led illuminants, inadmissible overheating of illuminants or lamps, etc., to achieve reliable cooling effect, enhance natural convection, and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

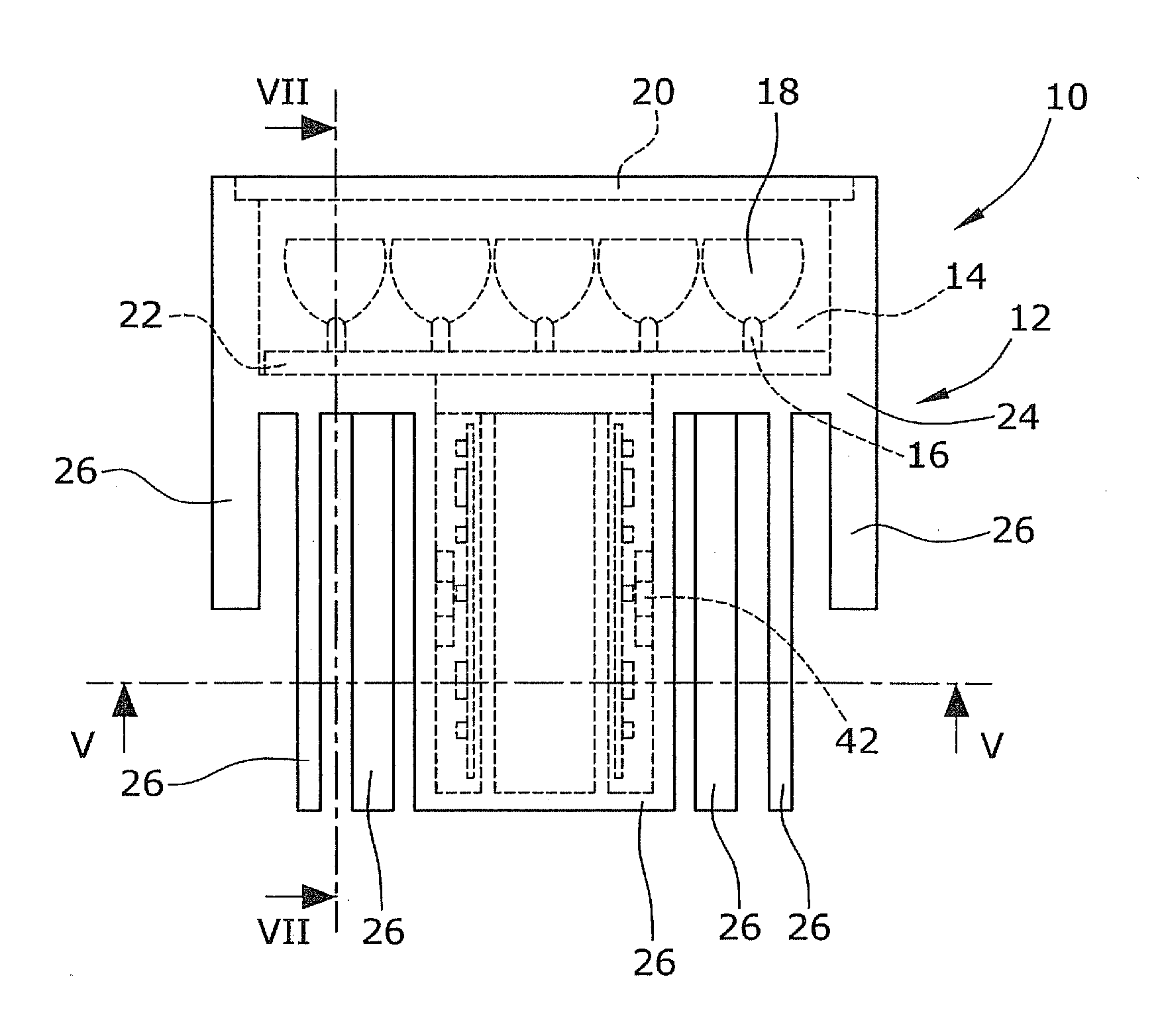

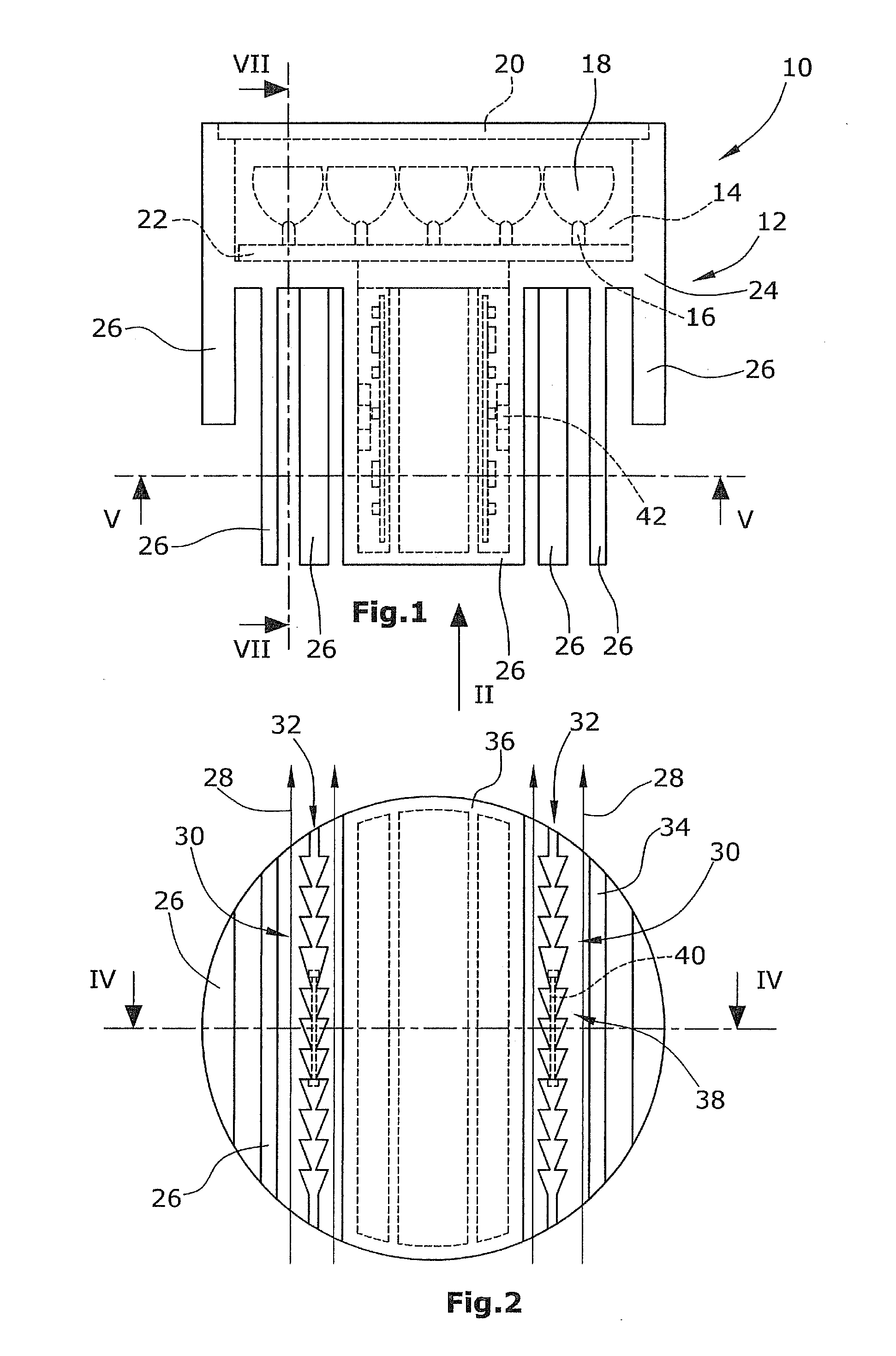

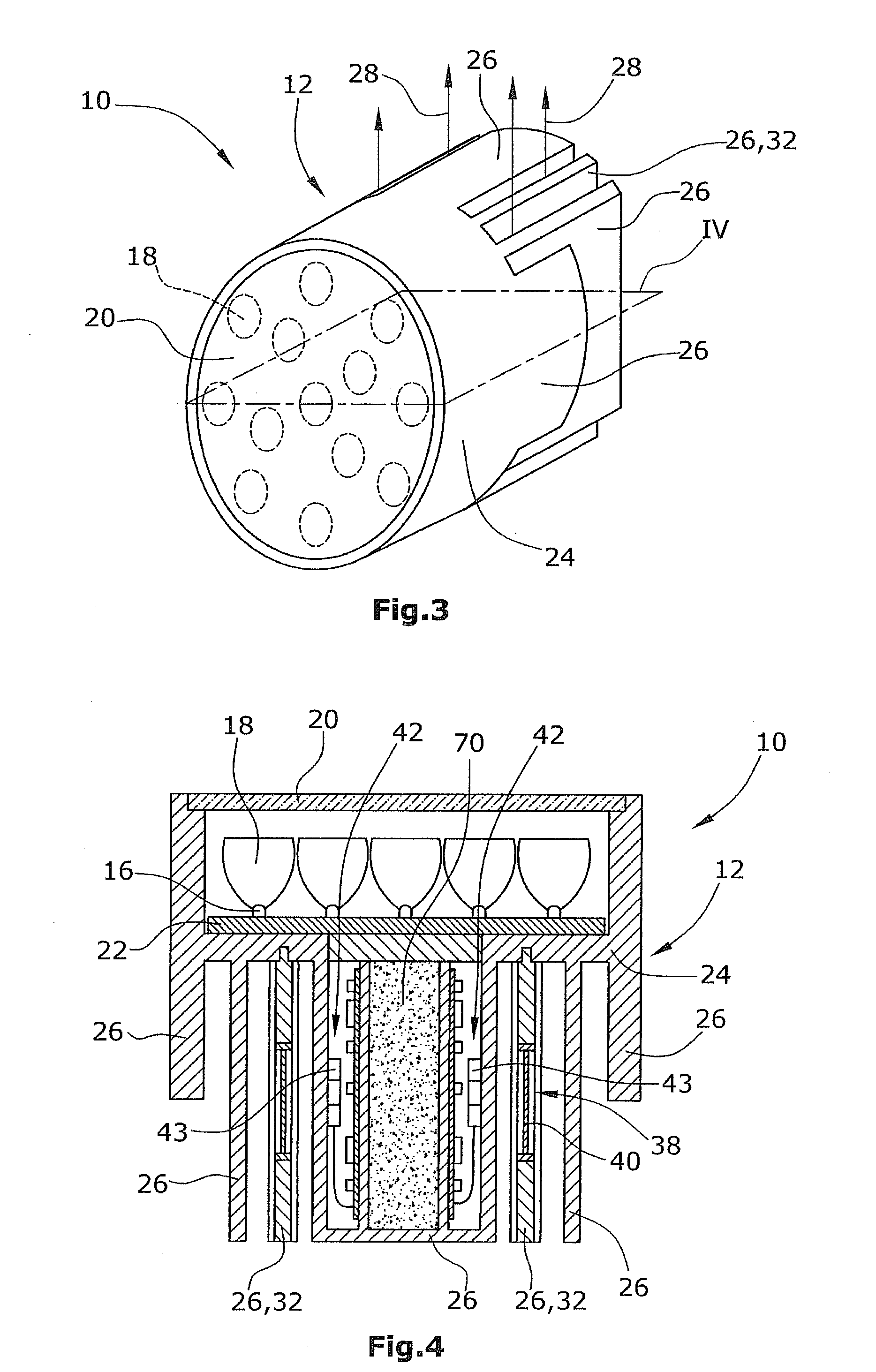

[0042]In FIGS. 1 to 3, an LED aircraft light 10 is shown in lateral, rear and perspective view. Said aircraft light 10 comprises a housing 12 provided with a receiving chamber 14. In said receiving chamber 14, a plurality of LEDs 16 are arranged whose light will be fed into (TIR) light conductors 18 which in turn will radiate this light to the outside via a lighting plate or a transparent cover 20. It should be noted that the use of TIR is not absolutely necessary for the invention. Within the framework of the invention, also other LED illuminants with or without light-conducting optical elements can be used.

[0043]In the present embodiment, said LEDs 16 are high-performance LEDs and are held on a common support plate 22. Said support plate 22 is in thermally conductive contact with a cooling body 24 which can form said housing 12—or a part thereof—of aircraft light 10 and which comprises individual cooling plate elements 26. Said cooling body 24 is provided with a device for generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com