Dispenser for roll materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

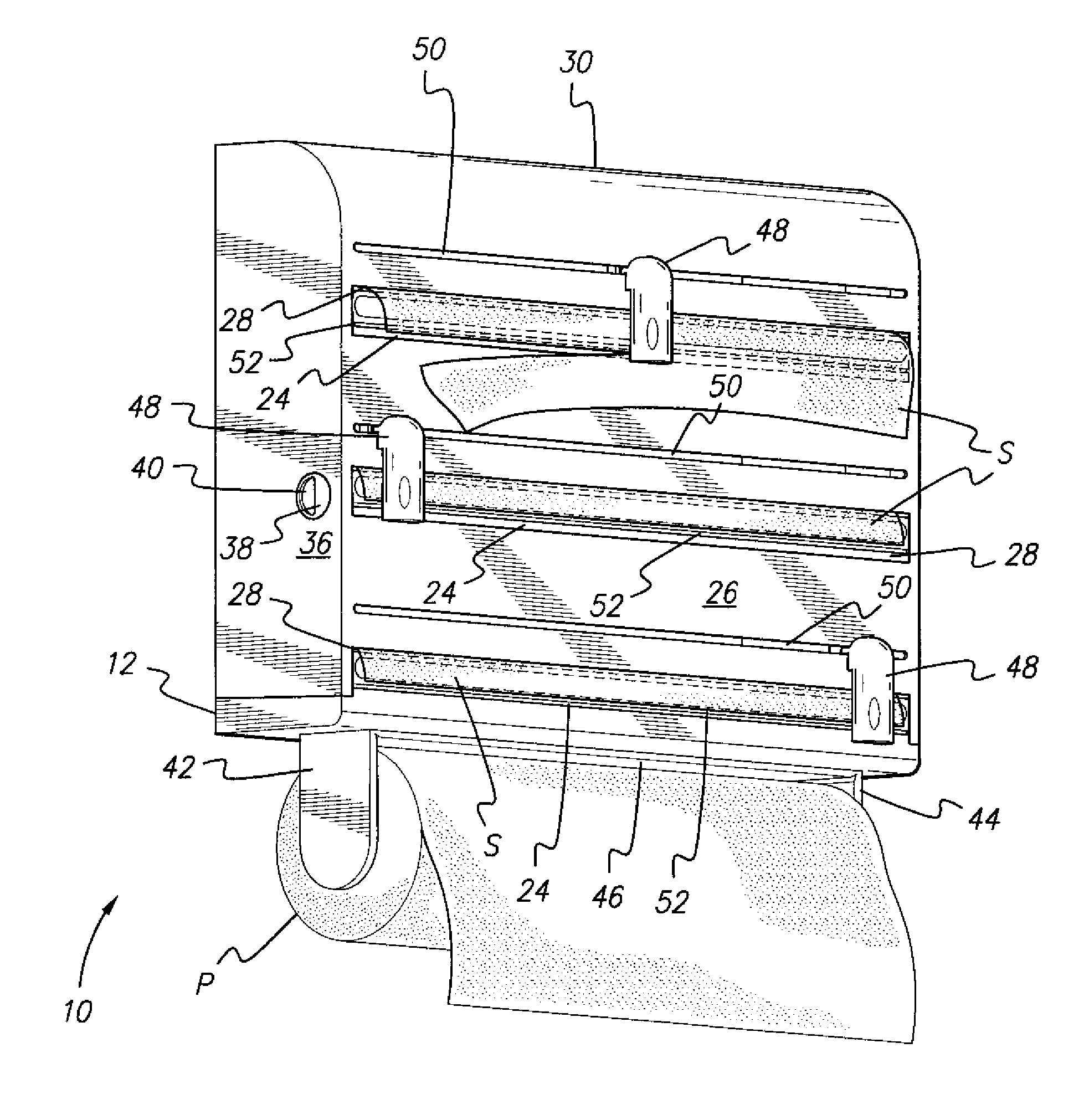

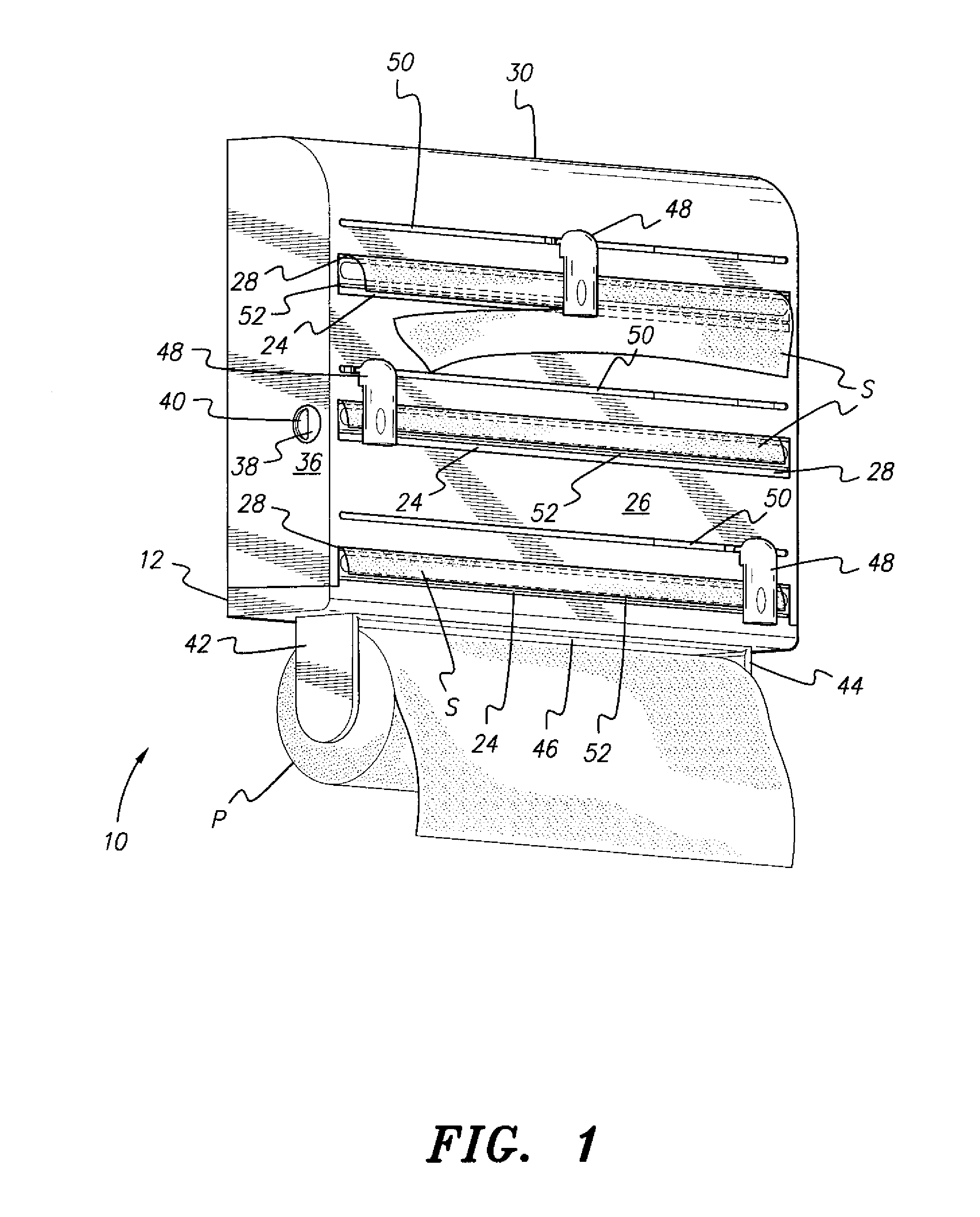

[0018]FIG. 1 of the drawings provides a perspective view of the dispenser for roll materials, designated as dispenser 10 in the drawings. The dispenser 10 provides storage and dispensing for three rolls of material contained therein, but it will be seen that the dispenser may be configured to hold and dispense more or fewer rolls of material. For example, a two-roll dispenser 110 is illustrated in FIG. 3. The two dispensers 10 and 110 differ only in the number of compartments provided for roll storage and have various components in common with one another.

embodiment 110

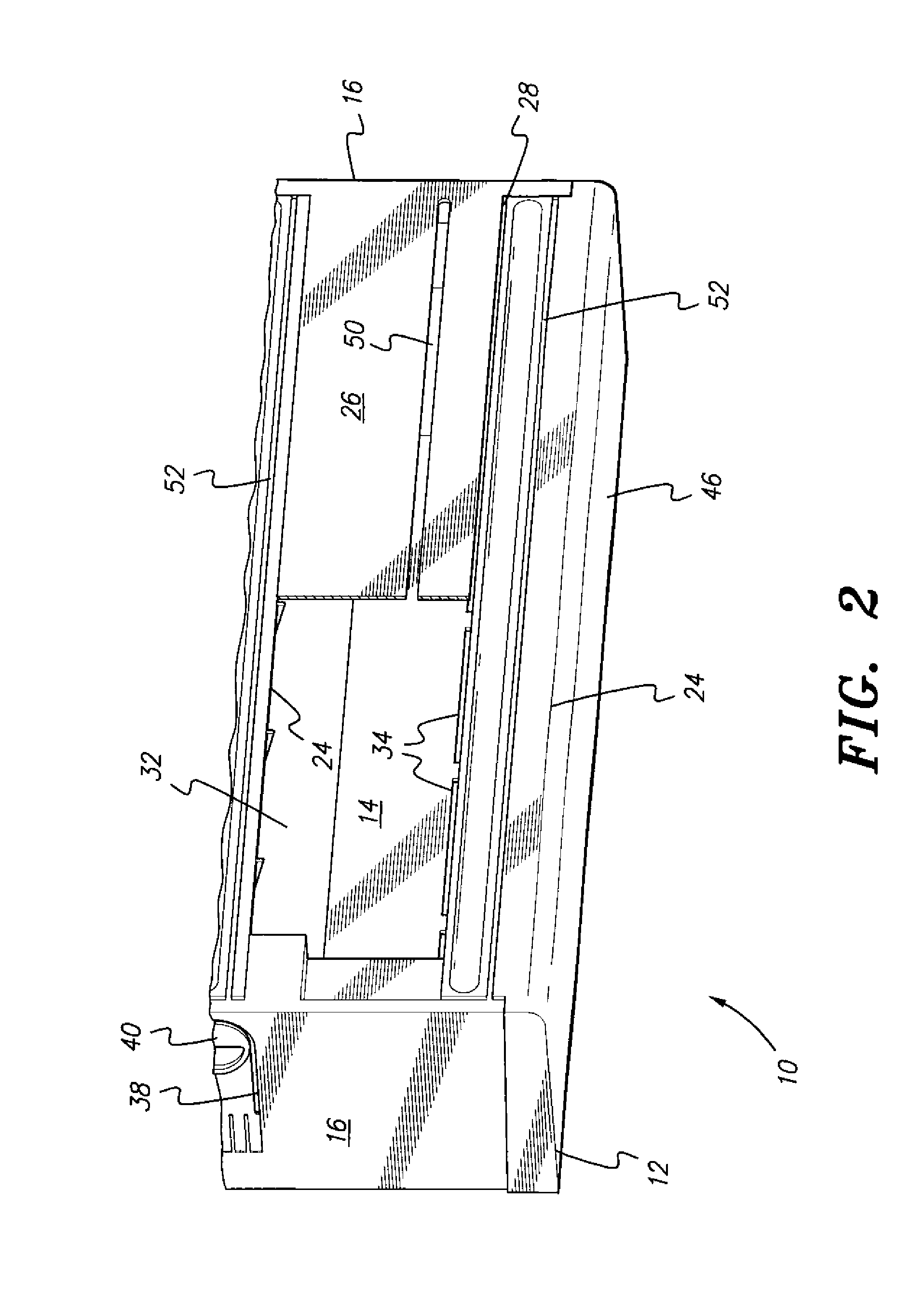

[0019]The dispenser 10 includes a cabinet 12 (mostly concealed behind the front cover in FIG. 1, but shown partially in FIG. 2). The cabinet has a back panel 14 with mutually opposed left and right side panels 16 and 18 (the right side panel 18 being similar to, but somewhat taller than, the right side panel 118 of the dispenser 110 of FIG. 3). The back panel 14 is adapted for mounting to any convenient and substantially vertical surface, e.g., the side of an existing cabinet, a wall, or a door using screws, adhesives, or other conventional attachment means. The back panel 14 (or 114, in the embodiment 110 of FIG. 3) need not be continuous, but may comprise a plurality of sections in order to save material.

[0020]A plurality of shelves extends forward from the back panel and between the two side panels, as shown by the shelves 120 of the dispenser 110 of FIG. 3 extending from the back panel 114 and right side panel 118. Each shelf 120 has a forward edge 122 and a front ledge 124 depe...

embodiment 10

[0023]The various embodiments of the cabinets and their corresponding covers are preferably formed of an at least somewhat flexible and resilient material, such as a durable plastic or the like. The front cover, e.g., the cover 26 of the dispenser embodiment 10 of FIGS. 1 and 2, includes mutually opposed left and right flanges extending from the lateral edges of the cover 26, the left flange 36 being visible in FIG. 1. Each of the lateral flanges includes a latch passage therethrough, e.g., the latch passage 38 of the left flange 36 of the cover 26. Each of the side panels of the cabinet, e.g., the left side panel 16 of the cabinet 12 shown in FIGS. 1 and 2, has a flexible or resilient latch 40 protruding slightly outwardly therefrom. The forward portion of the latch 40 is not attached to the cabinet side panel 16, but the rearward end of the latch 40 extends from the side panel 16 and is formed of the same material. When the front cover 26 is installed over the cabinet 12, the latc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resilience | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com