Auxiliary marine vessel propulsion system

a technology for auxiliary marine vessels and propulsion systems, applied in marine propulsion, propulsive elements, vessel construction, etc., can solve the problems of a certain amount of hydrodynamic drag on the rudder, and achieve the effects of high torque, efficient operation, and increased power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

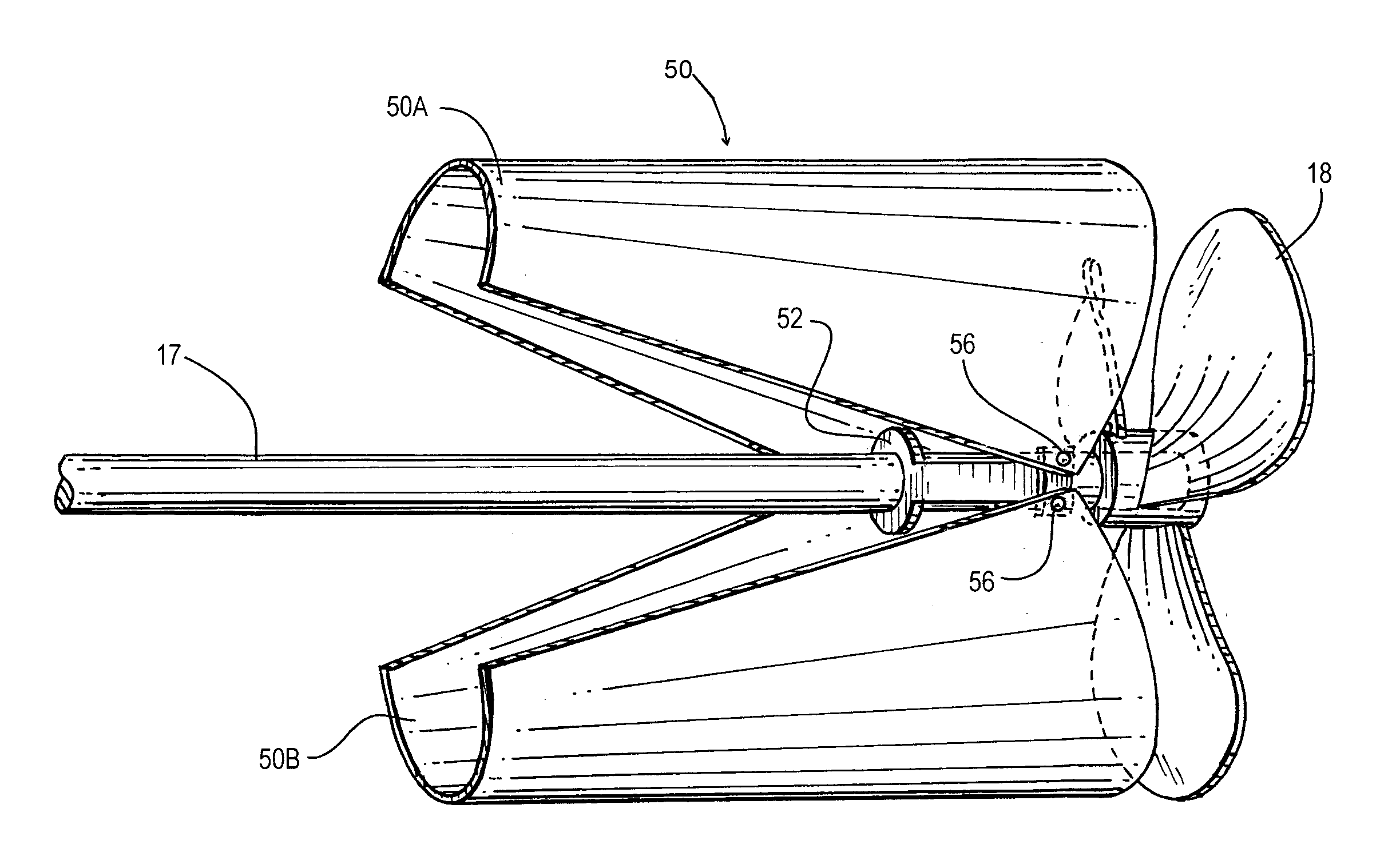

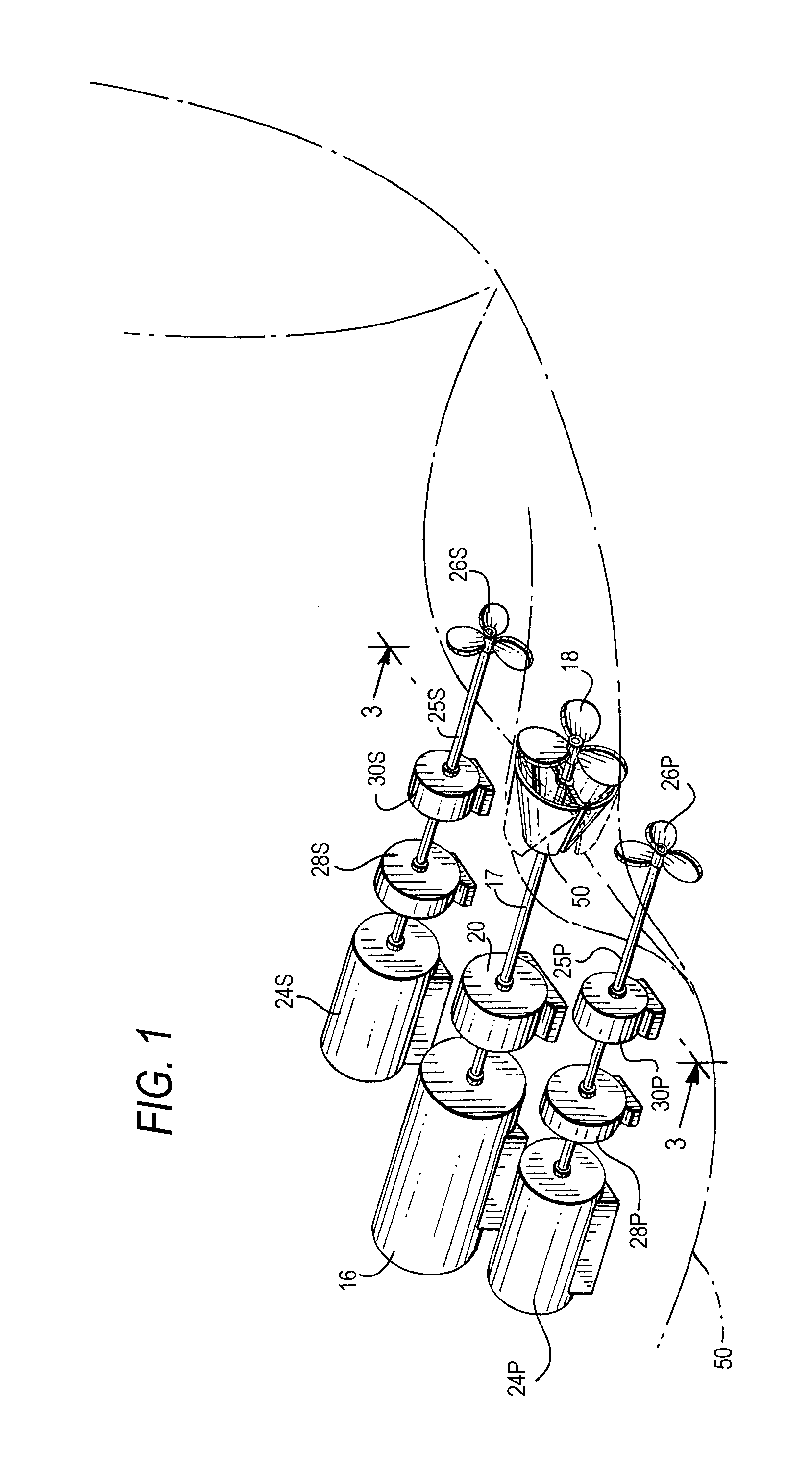

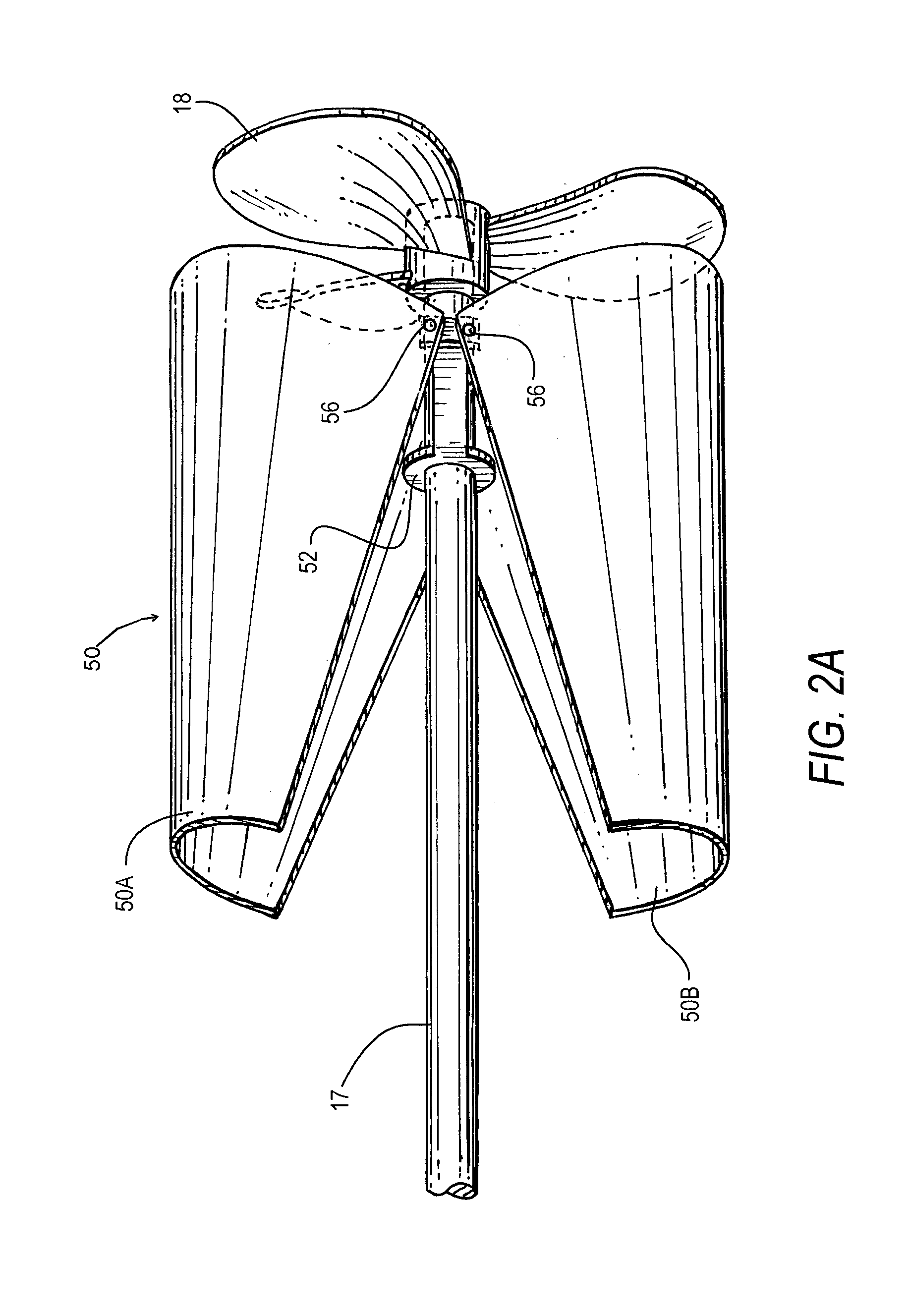

[0037]Referring to FIG. 1, a propulsion system 10 for a merchant vessel or the like is schematically depicted, including a main propulsion and drive subsystem 12 and a pair of auxiliary propulsion drive subsystems 14a and 14b, collectively referred to as 14, that can be operated independently of the main propulsion and drive subsystem 12. Generally, the main propulsion and drive subsystem 12 propels the vessel under normal operating conditions in accordance with known and conventional practices. According to the present invention, if the main propulsion drive subsystem 12 fails, or when the main propulsion drive subsystem 12 must be shut down for routine or unscheduled maintenance while at sea, the auxiliary propulsion drive subsystem 14 is used to propel the vessel, thereby offering reliable back-up propulsion. As will be understood by one of ordinary skill in the art, in a preferred embodiment the pair of auxiliary systems 14a and 14b flank the main drive system 12 at correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com