Double clutch

a double clutch and clutch technology, applied in the field of double clutches, can solve the problems of extremely compact construction and require less installation space, and achieve the effect of preventing cross-talk between the two single clutches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

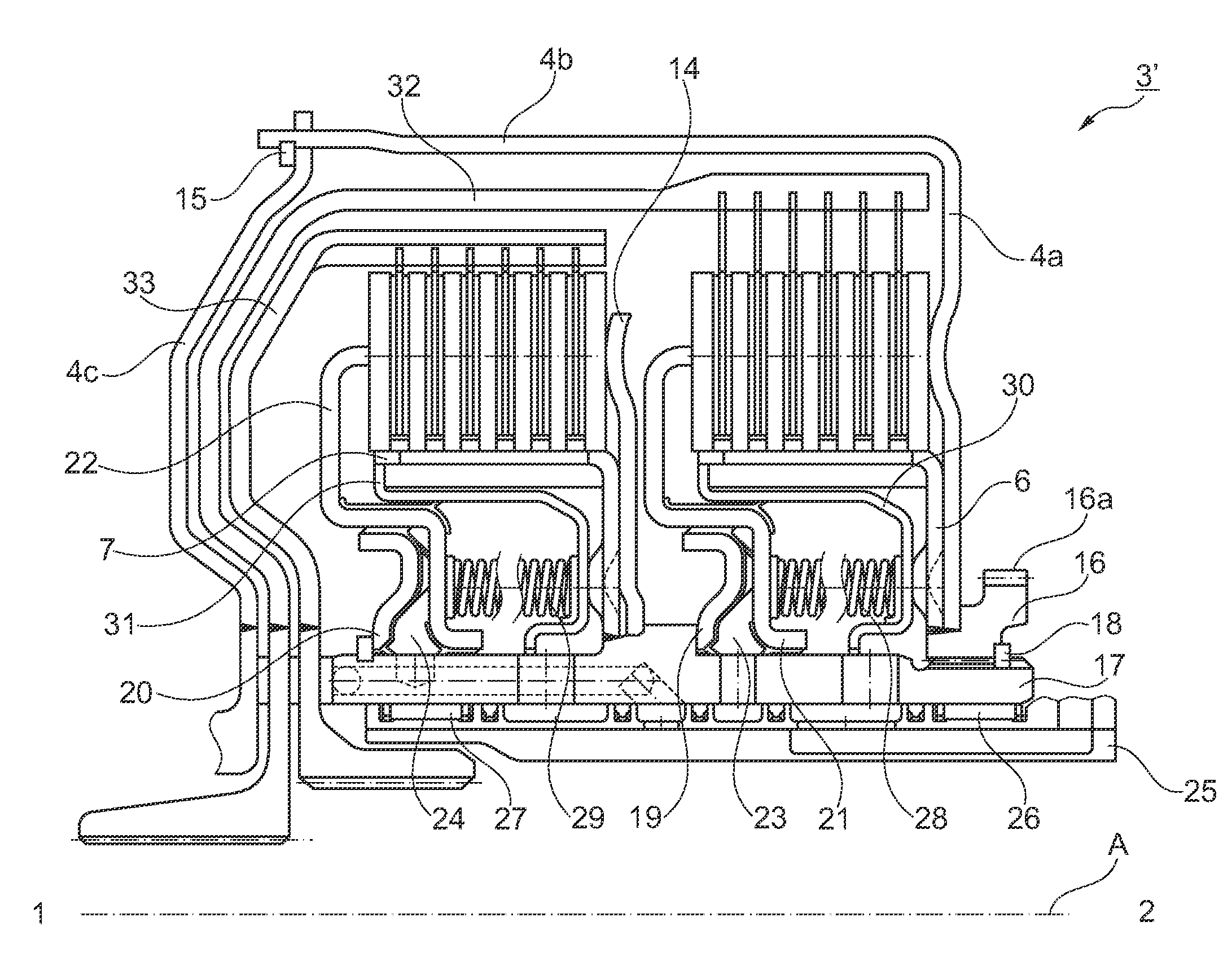

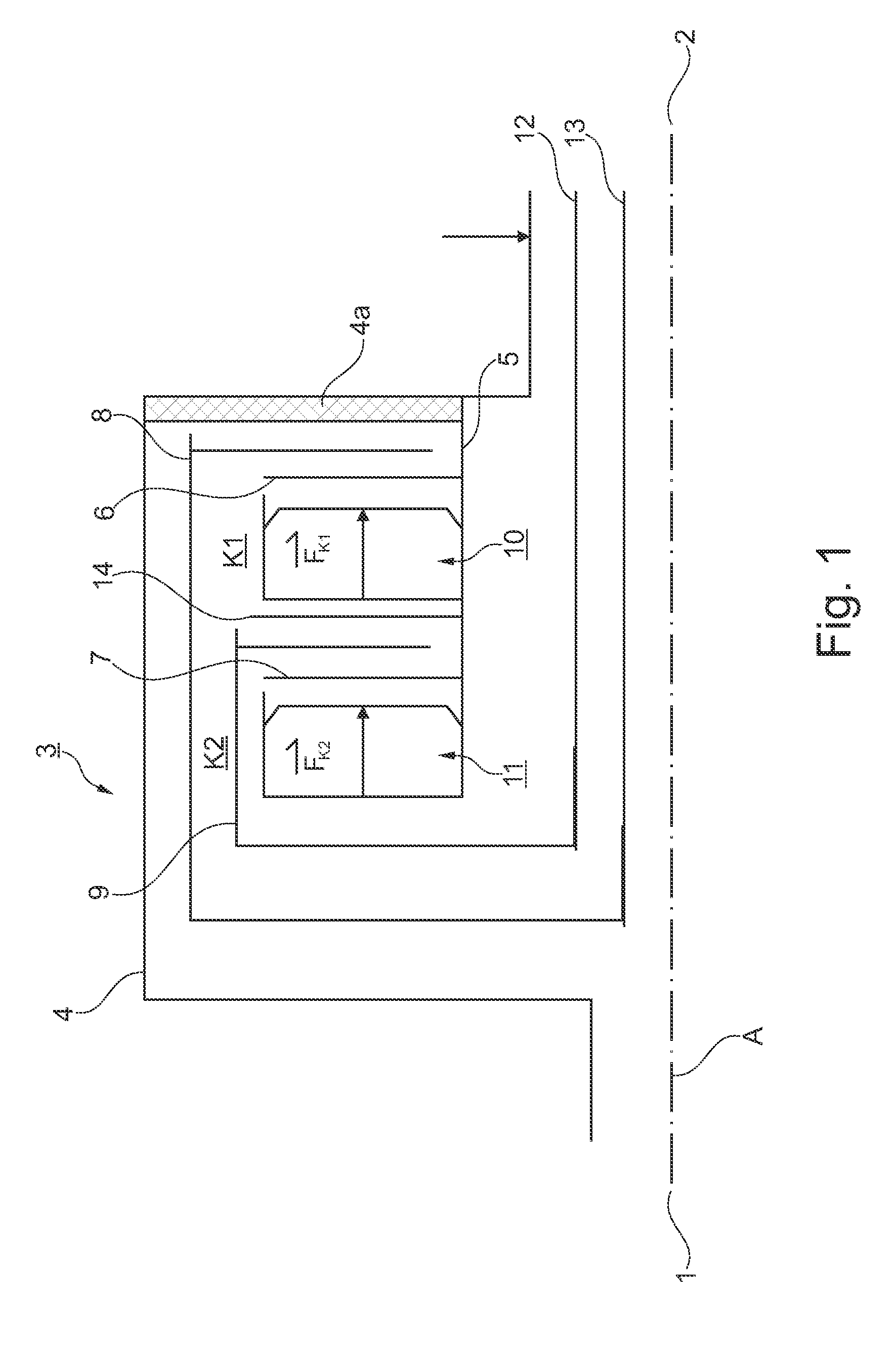

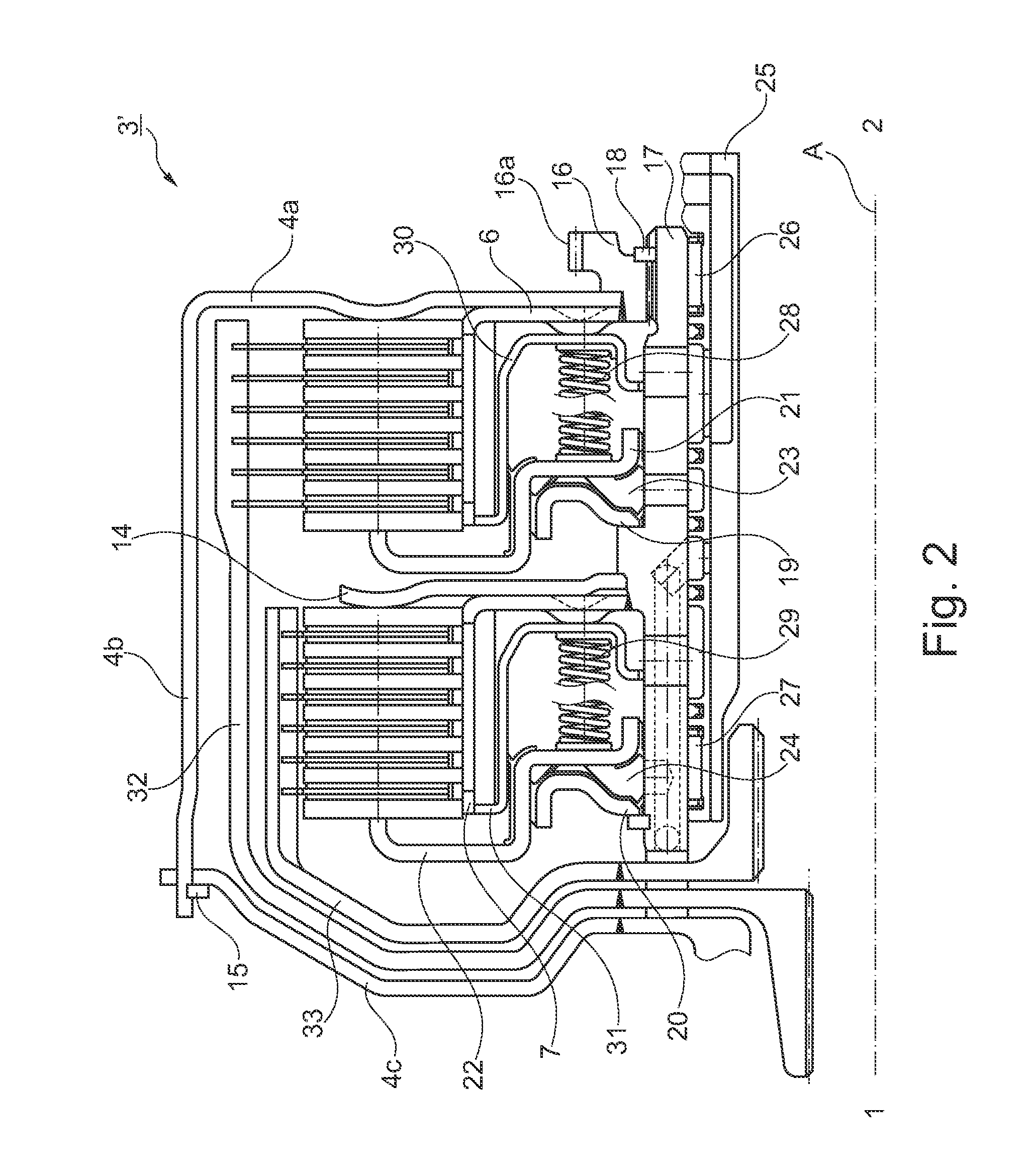

[0018]Here, FIG. 1 is a schematic illustration of the drive train of a vehicle, with a drive 1, a double clutch transmission 2, and a double clutch device 3 arranged between the drive 1 and the double clutch transmission 2. In this case, the torque generated by the drive 1 (preferably an internal combustion engine or an electric drive, or a combination of internal combustion engine and electric drive) is transmitted around the double clutch arrangement 3 via the clutch housing 4 to a clutch hub 5. The clutch hub 5 is connected to an input disk carrier 6 of the first single clutch K1 and to an input disk carrier 7 of a second single clutch K2. The single clutches K1 and K2 have disk packets (which are not shown individually in FIG. 1) that each consist of at least one input side friction disk and one output side friction disk. The output side friction disks are connected to an output side disk carrier 8 for the single clutch K1 and an output disk carrier 9 for the single clutch K2. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com