Method and apparatus for chemical data repository

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

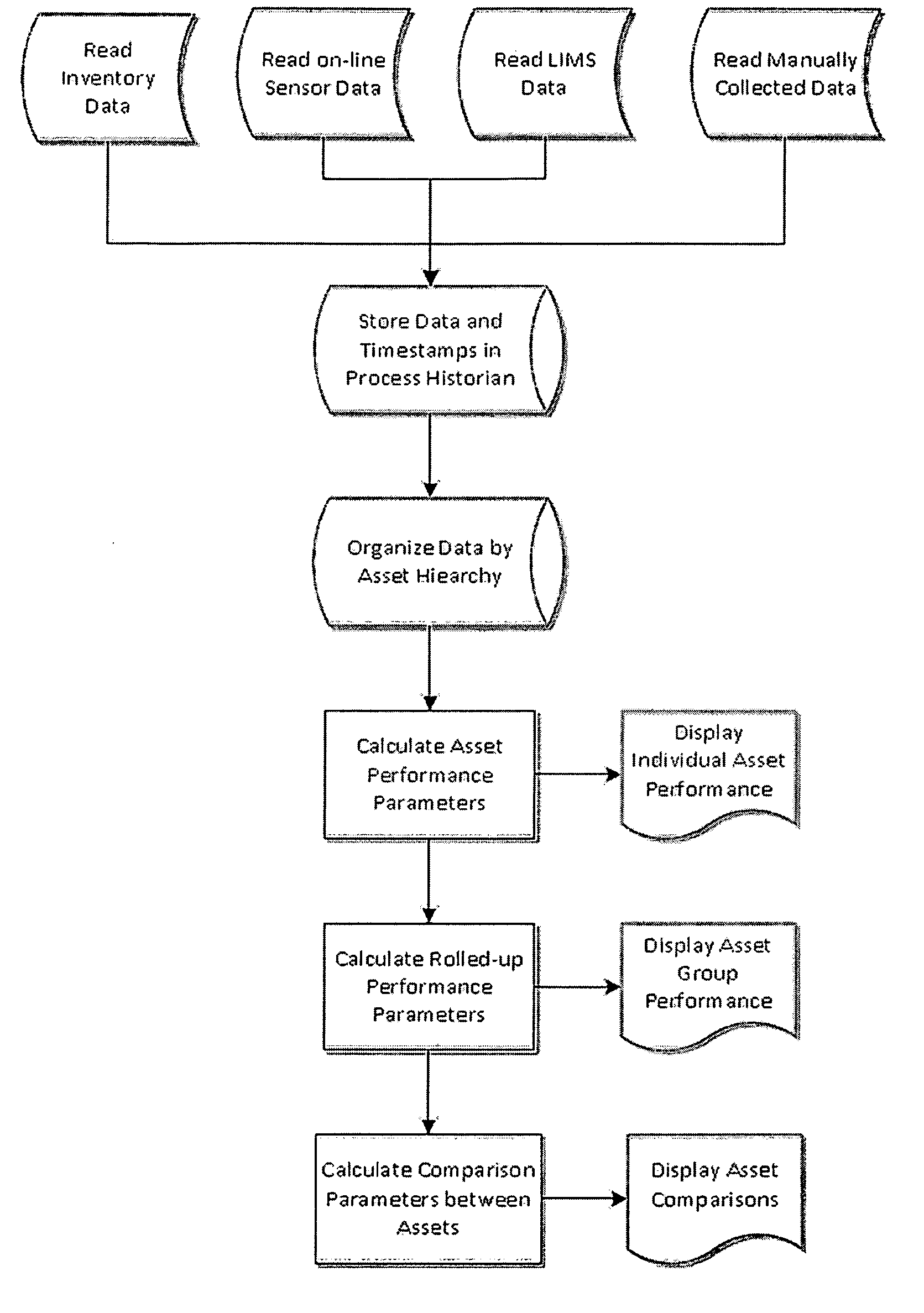

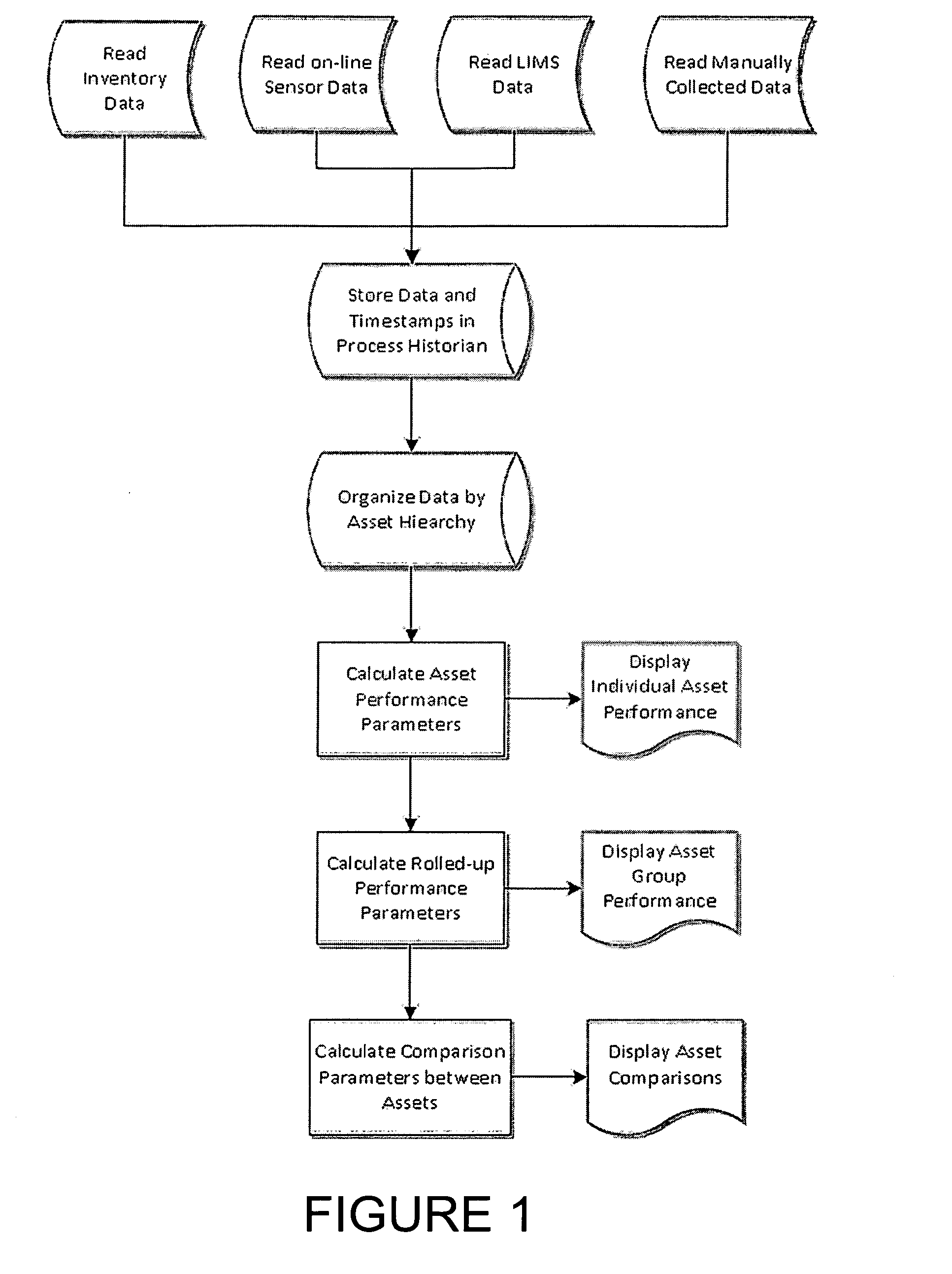

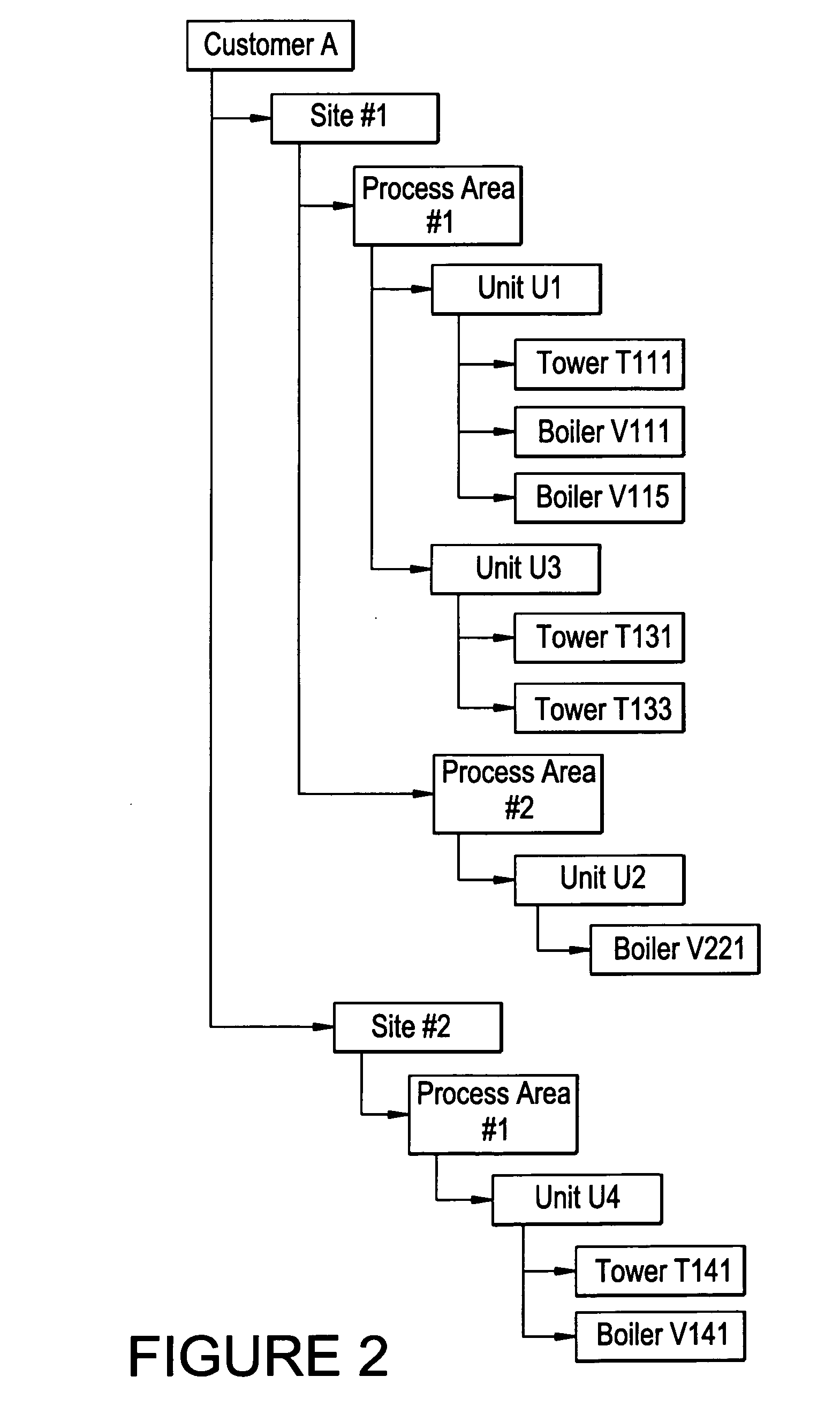

[0014]In at least one embodiment, a chemical management system is provided which comprises at least one computer and at least one source of data, which is input into the computer. The data source comprises at least one source of raw data related to the item(s) under management selected from: control systems output, wet chemistry test results, manual observation data, data collected by handheld equipment, laboratory management systems (LIMS), gauges, transmitters, statistical process control, statistical quality control, inventory management software, and any combination thereof. This information is stored by the computer and indexed by time. The data sources may also include information collected by a process historian such as but not limited to that described by US 2009 / 0149981.

[0015]The collected data is various readings of various specifications (or specs) of relevance various assets. Collected specs include but are not limited to temperature, pressure, pH, voltage, density, visc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com