Valve

a valve and valve body technology, applied in the field of valves, can solve the problems of prolonging the service life and reliability of the valve, and achieve the effects of improving sealing function, preventing fluid flow, and being durable and reliabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

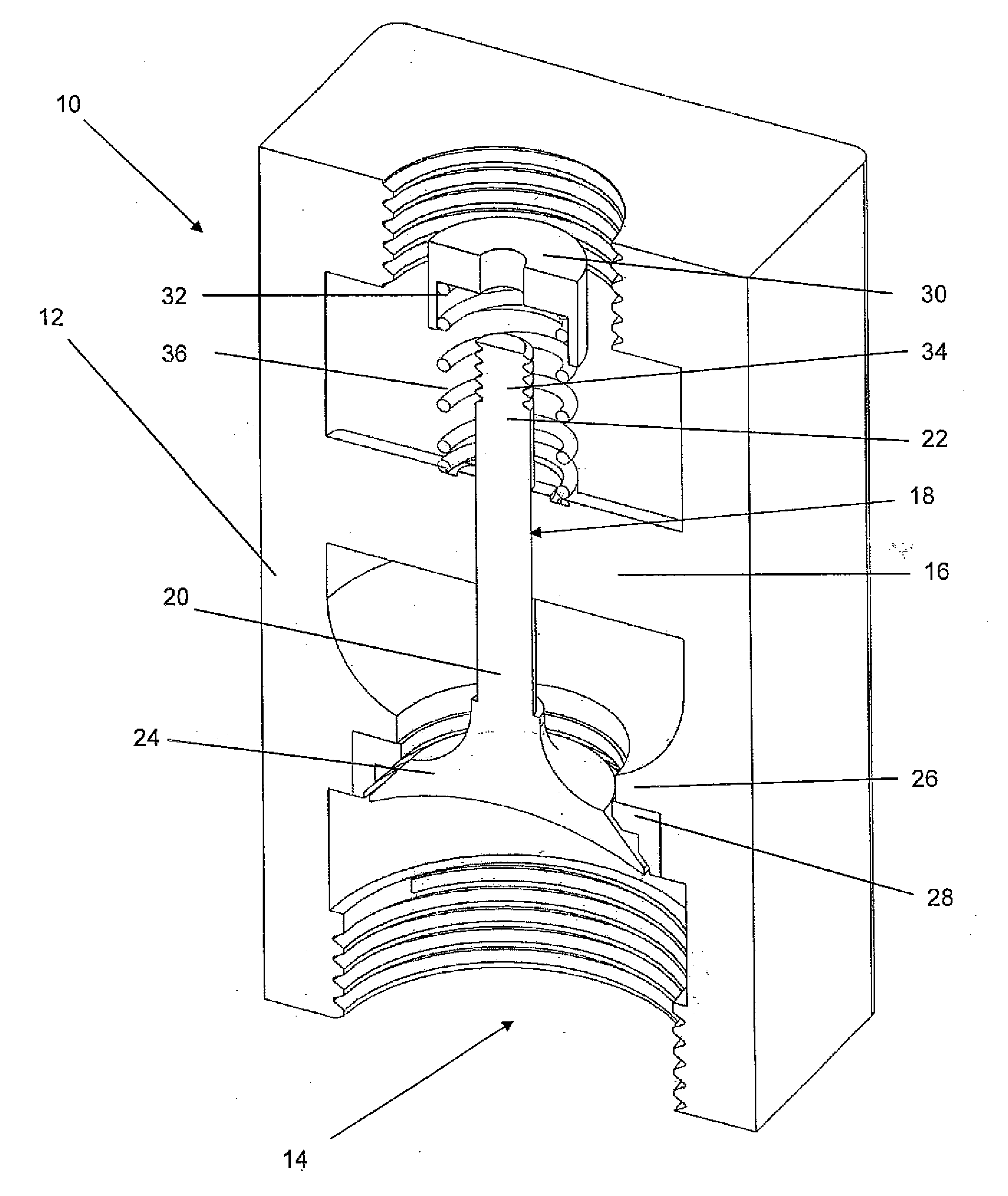

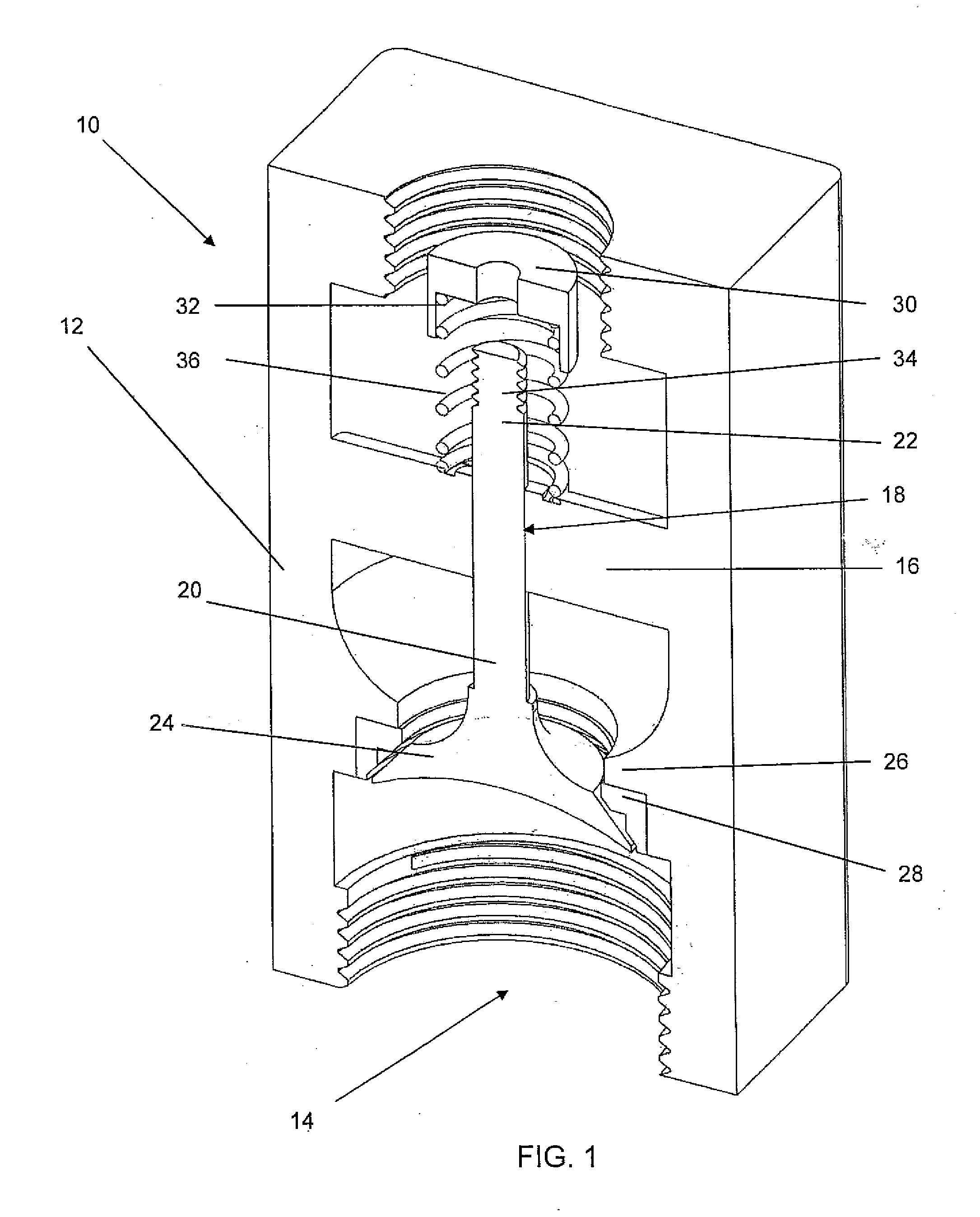

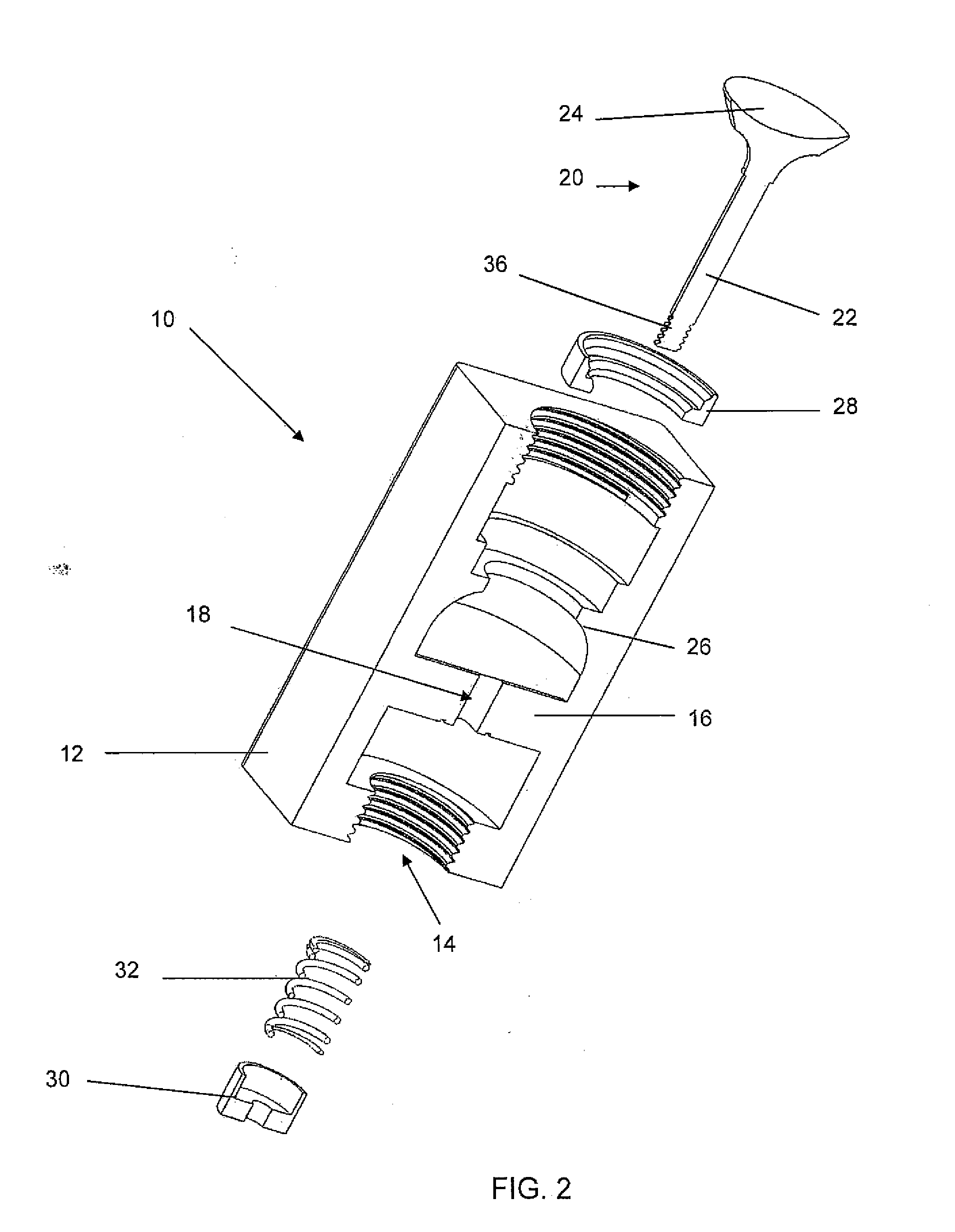

[0020]Illustrated in FIGS. 1 and 2, generally at 10, is a valve representing a preferred embodiment of the present invention. The valve 10 has a generally elongated body 12 with a throughbore 14 for the flow of fluids through the valve 10 under desired conditions. Extending radially across the throughbore 14 from a side wall of the body 12 to an opposite sidewall is a valve guide 16 having a guide hole 18 aligned longitudinally of the valve body 12. A valve stem 20 has an extended stem portion 22 and a valve plug portion 24. The stem portion 22 is received inside the guide hole 18 for reciprocal longitudinal guided movement of the valve stem 20 inside the valve body 12.

[0021]Included in the valve body 12 is a seat support 26 that defines a circular aperture. A valve seat 28 is fitted into and supported by the seat support 26. The valve plug portion 24 is brought into and out of contact with the valve seat 28 as the valve stem 20 moves reciprocally inside the valve body 12. A cap 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com