Method and apparatus for predicting maintenance needs of a pump based at least partly on pump performance analysis

a technology of pump performance and prediction method, applied in the direction of positive displacement liquid engine, testing/monitoring control system, instruments, etc., can solve the problems of inability to achieve the effect of pump operation, theory does not support the shape of such a relation, and the pump cannot be practical, so as to achieve the effect of maximum pump operation efficiency, prolonging the life of the pump, and increasing the efficiency of the pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

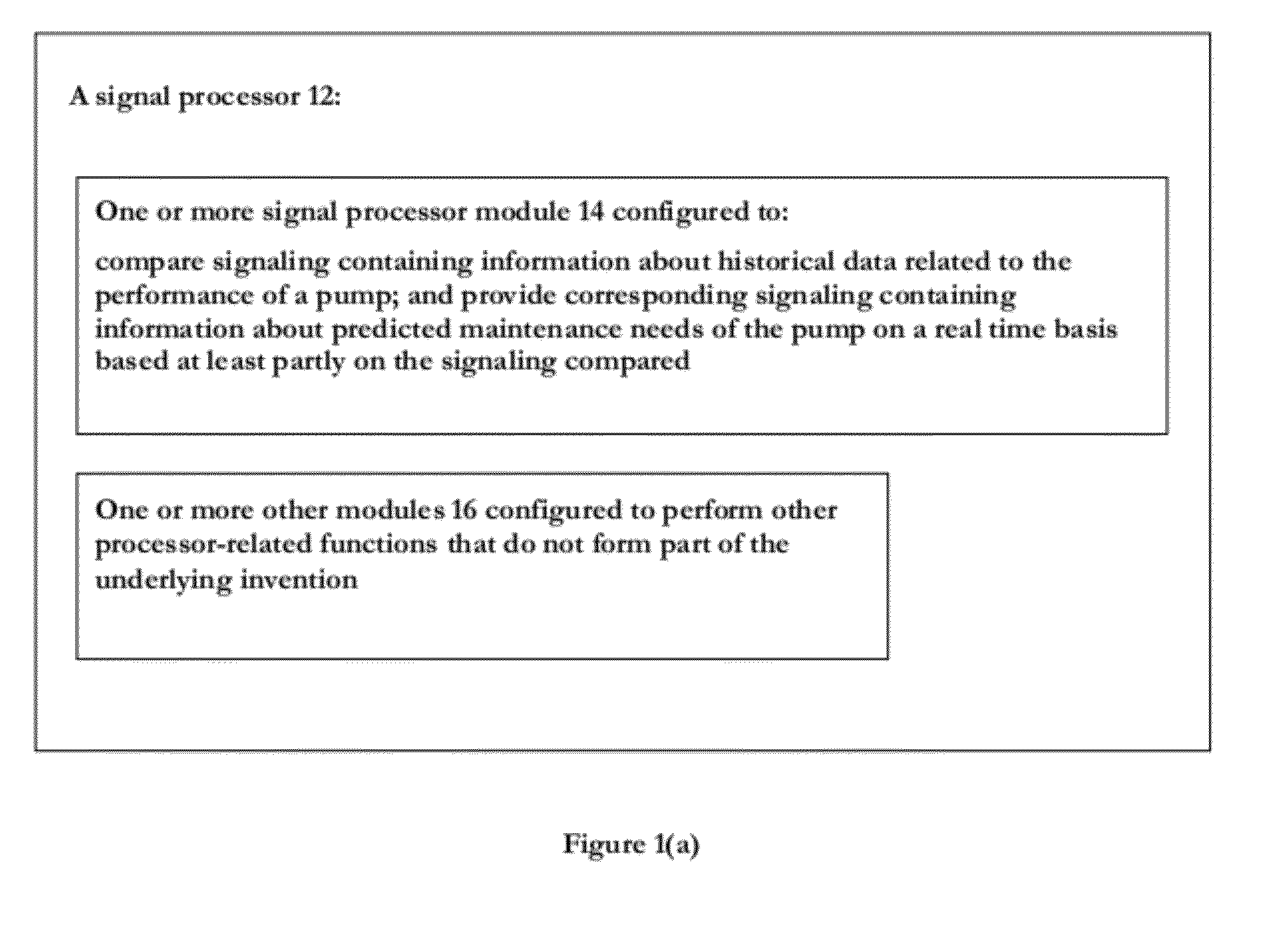

[0050]FIG. 1(a) shows a signal processor 12 comprising one or more signal processor modules 14 and one or more other modules 16. The one or more signal processor modules 12 is configured to compare signaling containing information about historical data related to the performance of a pump; and provide corresponding signaling containing information about predicted maintenance needs of the pump on a real time basis based at least partly on the signaling compared containing information about the historical data related to the performance of the pump. The one or more other modules 16 is configured to cooperate with the one or more signal processor modules 12 and perform other processor-related functions that do not form part of the underlying invention, including input / output functionality, memory functionality, etc.

[0051]By way of example, the one or more signal processor modules 12 may be configured to compare over time one signal containing information about the hydraulic power gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com