Deep penetration arrow insert

a deep penetration, arrow technology, applied in the direction of arrows, throw games, sport apparatus, etc., can solve the problems of unbalanced air flow, unsatisfactory, unpredictable turbulence in air flow along the length of the shaft, etc., to improve the flight characteristics and penetration of the target.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

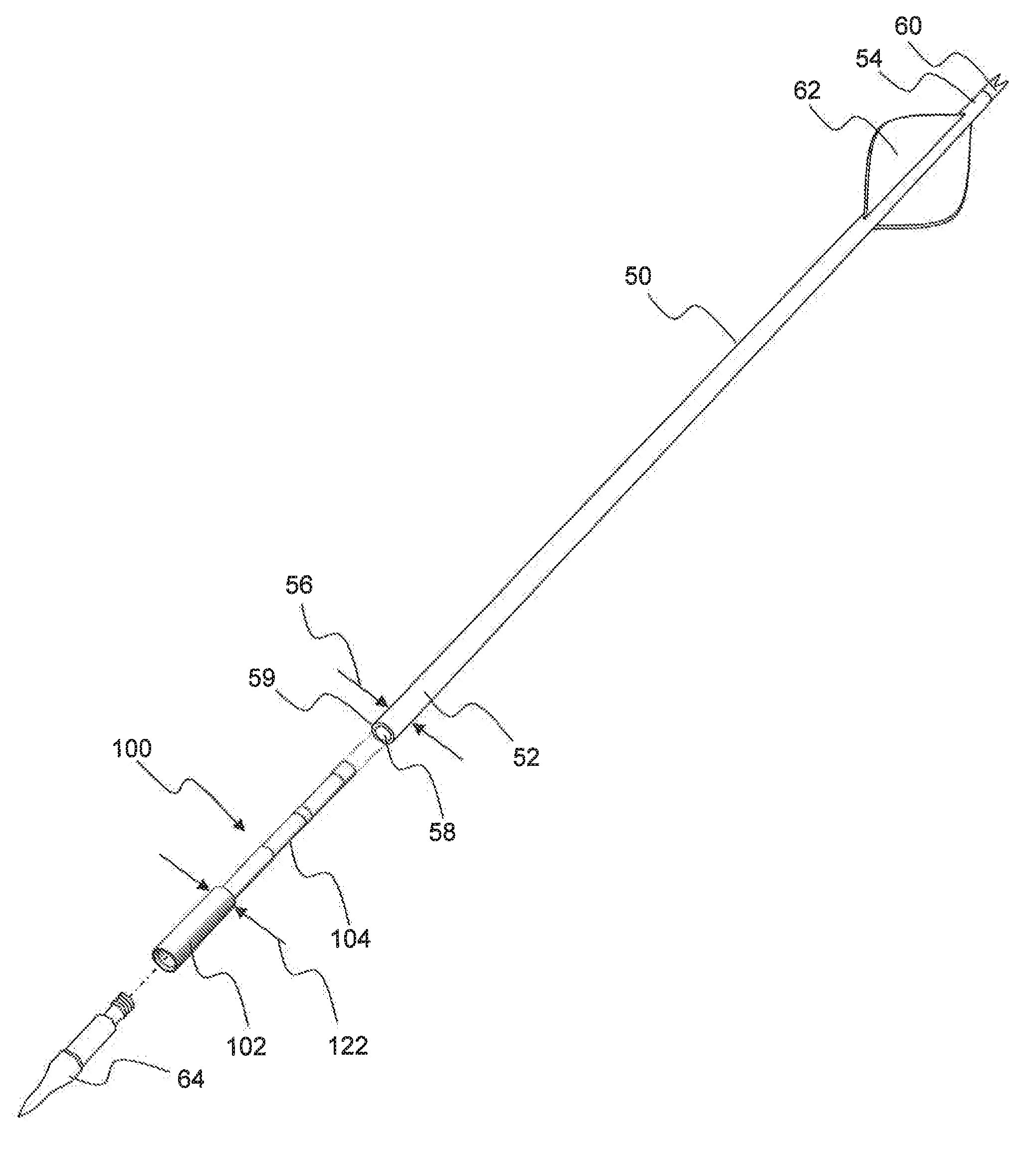

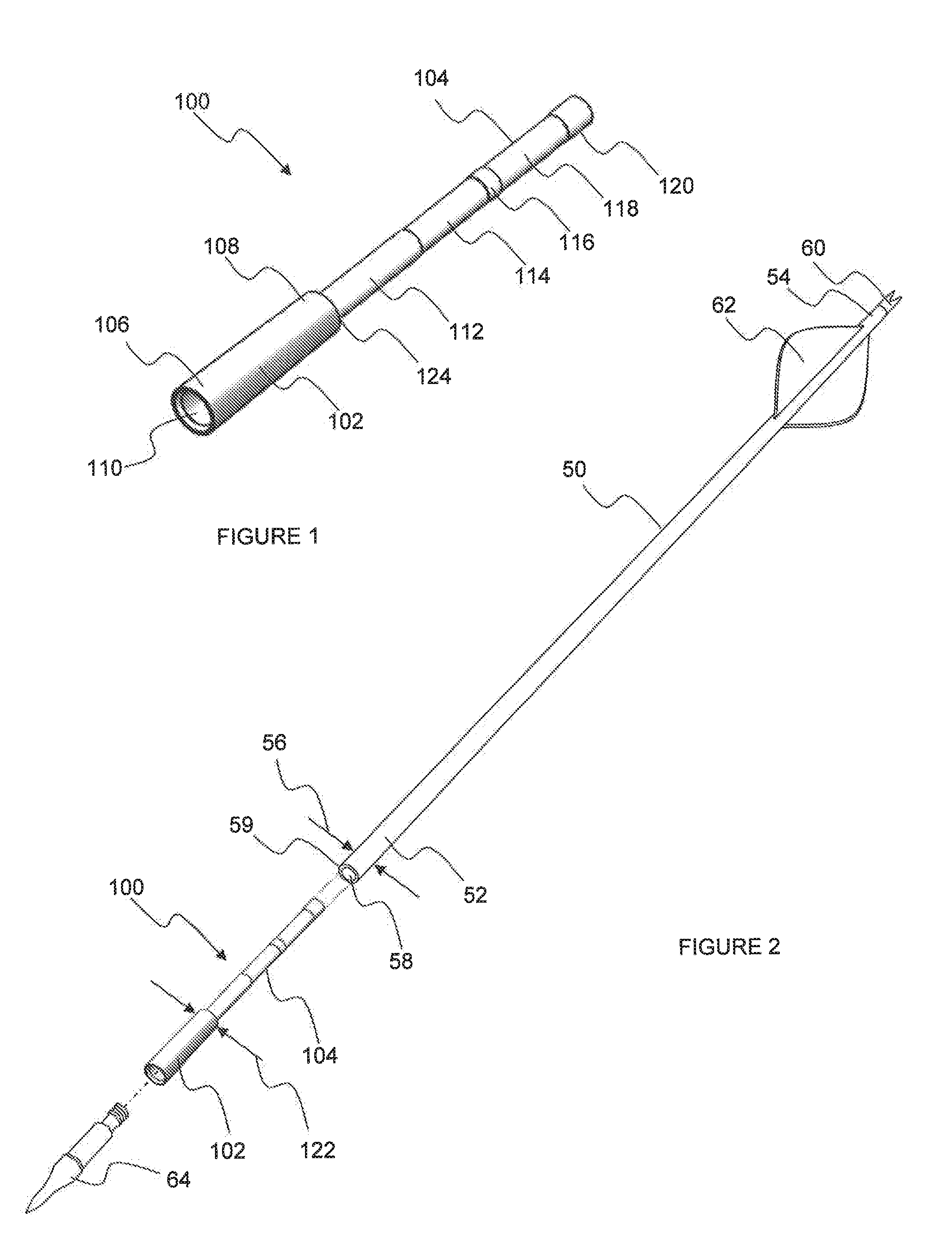

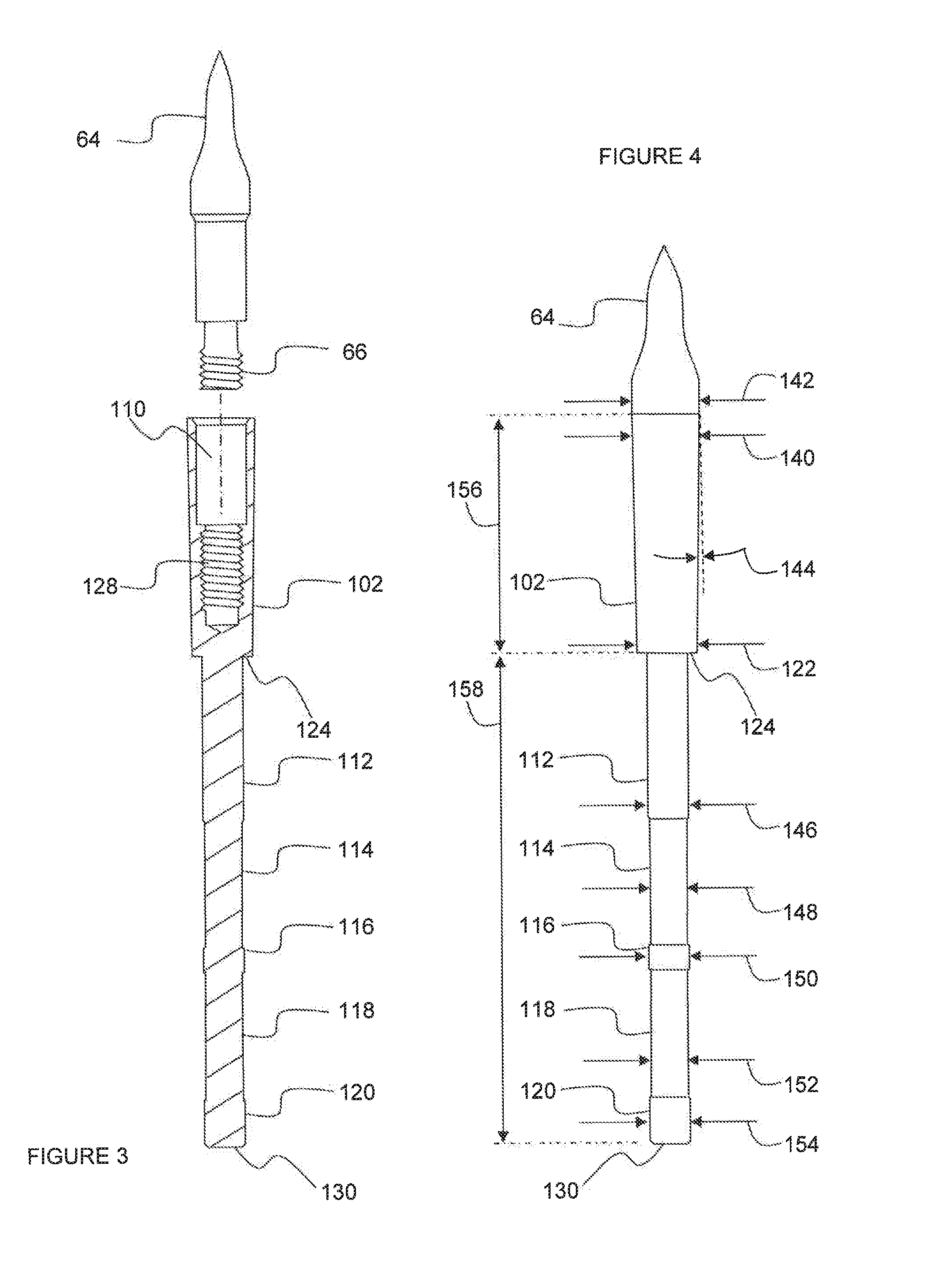

[0021]Referring now to FIG. 1, a perspective view of the deep penetration arrow insert of the present invention is shown and generally designated 100. Insert 100 includes a point receiver 102 and an insert rod 104. Point receiver 102 has a front 106 which tapers longitudinally down to a base 108, and is formed with a point-receiving bore 110.

[0022]Rod 104 extends from point receiver 102 and includes several sections having differing diameters. From this view, rod 104 begins with section 112, and narrows to section 114 and 118, and has two larger-diameter sections 116 and 120. As will be discussed in greater detail in conjunction with FIG. 4, these varying diameters are useful in mounting and securing the insert 100 to an arrow shaft.

[0023]FIG. 2 is a perspective exploded view of the penetrating insert 100 for arrow 50 of the present invention as shown in use with an arrow 50. Arrow 50 includes a shaft head 52 and a shaft end 54. As shown, arrow 50 has an outer shaft diameter 56, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com