Polyolefin and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example 1

Preparation of the First Metallocene Catalyst—Synthesis of [tBu—O—(CH2)6—C5H4]2ZrCl2

[0127]6-chlorohexanol was used to prepare t-Butyl-O—(CH2)6—Cl according to the method that was described in the document (Tetrahedron Lett. 2951 (1988)), and NaCp was reacted in respects to this to obtain t-BUtYl-O—(CH2)B—C5H5 (yield 60%, b.p. 80° C. / 0.1 mmHg). In addition, t-Butyl-O—(CH2)6—C5H5 was dissolved in THF at −78 normal butyl lithium (n-BuLi) was slowly added thereto, the temperature was increased to room temperature, and the reaction was performed for 8 hours. The solution was additionally reacted at room temperature for 6 hours while the synthesized lithium salt solution was slowly added to the suspension solution of ZrCl4(THF)2 (1.70 g, 4.50 mmoD / THF (30 ml) at −78° C. All the volatile substances were dried under vacuum, and the hexane solvent was added to the obtained oily liquid substance and then filtered. After the filtered solution was dried under vacuum, hexane was added thereto t...

preparation example 2

Preparation of the First Metallocene Catalyst—Synthesis of [tBu—O—(CH2)6—C5H4]2HfCl2

[0130]6-chlorohexanol was used to prepare t-Butyl-O—(CH2)6—Cl according to the method that was described in the document (Tetrahedron Lett. 2951 (1988)), and NaCp was reacted in respects to this to obtain t-Butyl-O—(CH2)6—C5H5 (yield 60%, b.p. 80° C. / 0.1 mmHg). In addition, t-Butyl-O—(CH2)6—C5H5 was dissolved in THF at −78° C., normal butyl lithium (n-BuLi) was slowly added thereto, the temperature was increased to room temperature, and the reaction was performed for 8 hours. The solution was additionally reacted at room temperature for 6 hours while the synthesized lithium salt solution was slowly added to the suspension solution of HfCl4 (1.44 g, 4.50 mmoD / THF (30 mH) at −78° C. All the volatile substances were dried under vacuum, and the hexane solvent was added to the obtained oily liquid substance and then filtered. After the filtered solution was dried under vacuum, hexane was added thereto to...

preparation example 3

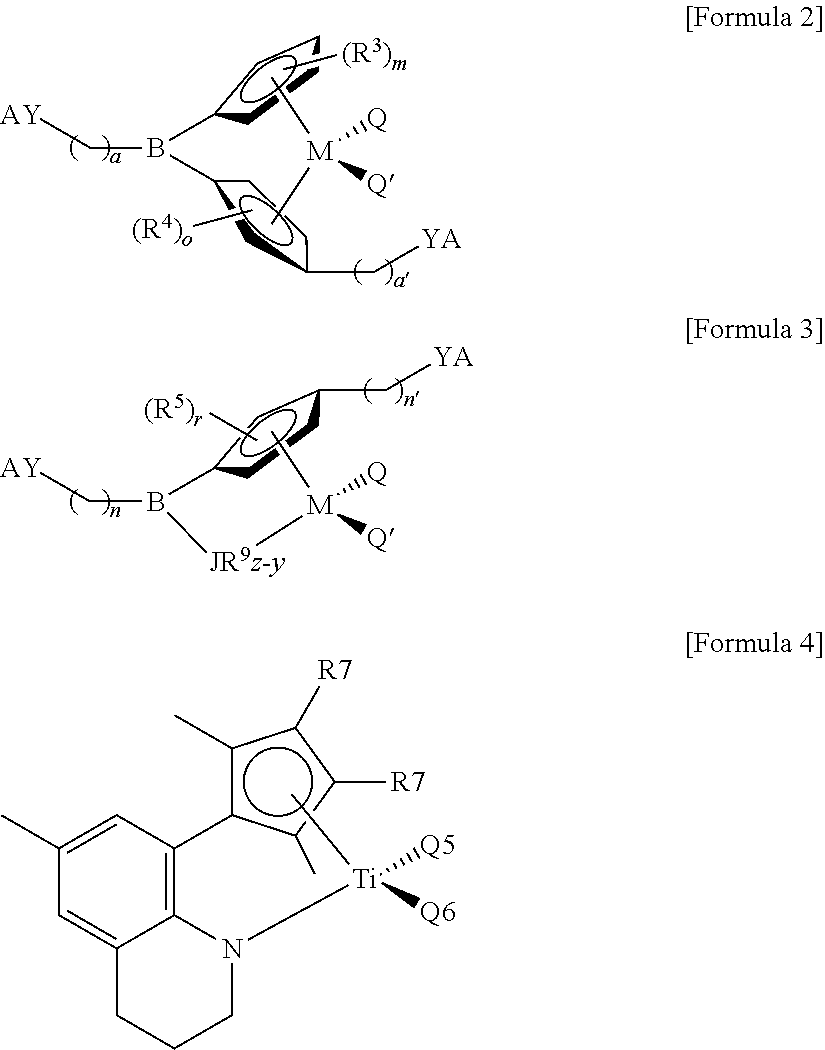

Preparation of the Second Metallocene Catalyst—Synthesis of [Methyl(6-T-Buthoxyhexyl)Silyl(.η5-TetramethylCp)(T-Butylamido)]TiCl2

[0133]After 50 g of Mg(s) was added to the 10 L reactor at normal temperature, 300 mL of THF was added thereto. After I2 was added in an amount of about 0.5 g, the reactor temperature was maintained at 50° C. After the reactor temperature was stabilized, 250 g of 6-t-buthoxyhexyl chloride was added to the reactor at a speed of 5 mL / min by using a feeding pump. According to the addition of 6-t-buthoxyhexyl chloride, it was observed that the reactor temperature was increased by about 4 and 5° C. While 6-t-buthoxyhexyl chloride was continuously added, the agitation was performed for 12 hours. The black reaction solution was obtained after reaction for 12 hours. After 2 mL of the formed black solution was sampled, water was added thereto to obtain the organic layer. Thus, 6-t-buthoxyhexane was confirmed by using the 1H-NMR. Through 6-t-buthoxyhexane, it could...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com