Ceiling Fan Controller Using a Dip Switch to Set Rotation Speed Thereof

a technology of fan controller and dip switch, which is applied in the direction of pump control, non-positive displacement fluid engine, climate sustainability, etc., can solve the problems of complex material management problems, lower efficiency of conventional induction motor, and inability to adjust to an appropriate power output, etc., to increase fabrication efficiency and simplify material management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]The present invention will be apparent from the following detailed description, which proceeds with reference to the accompanying drawings, wherein the same references relate to the same elements.

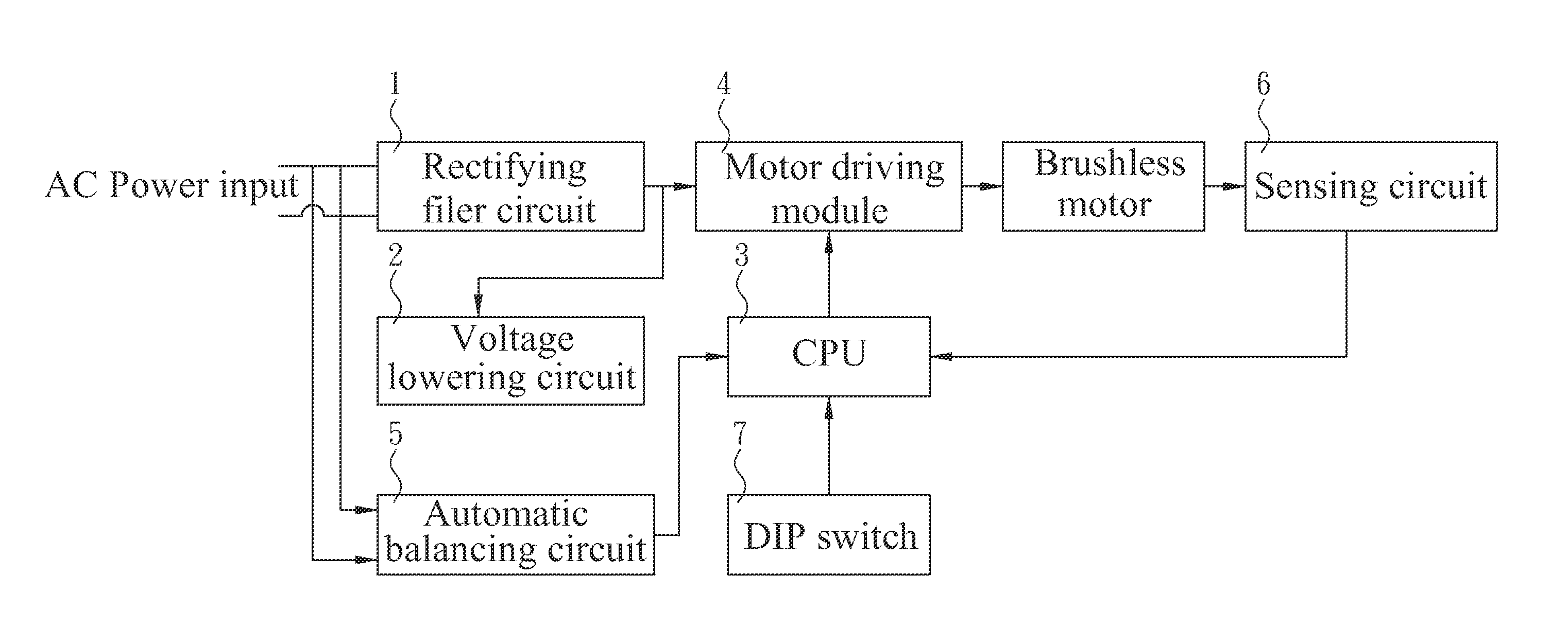

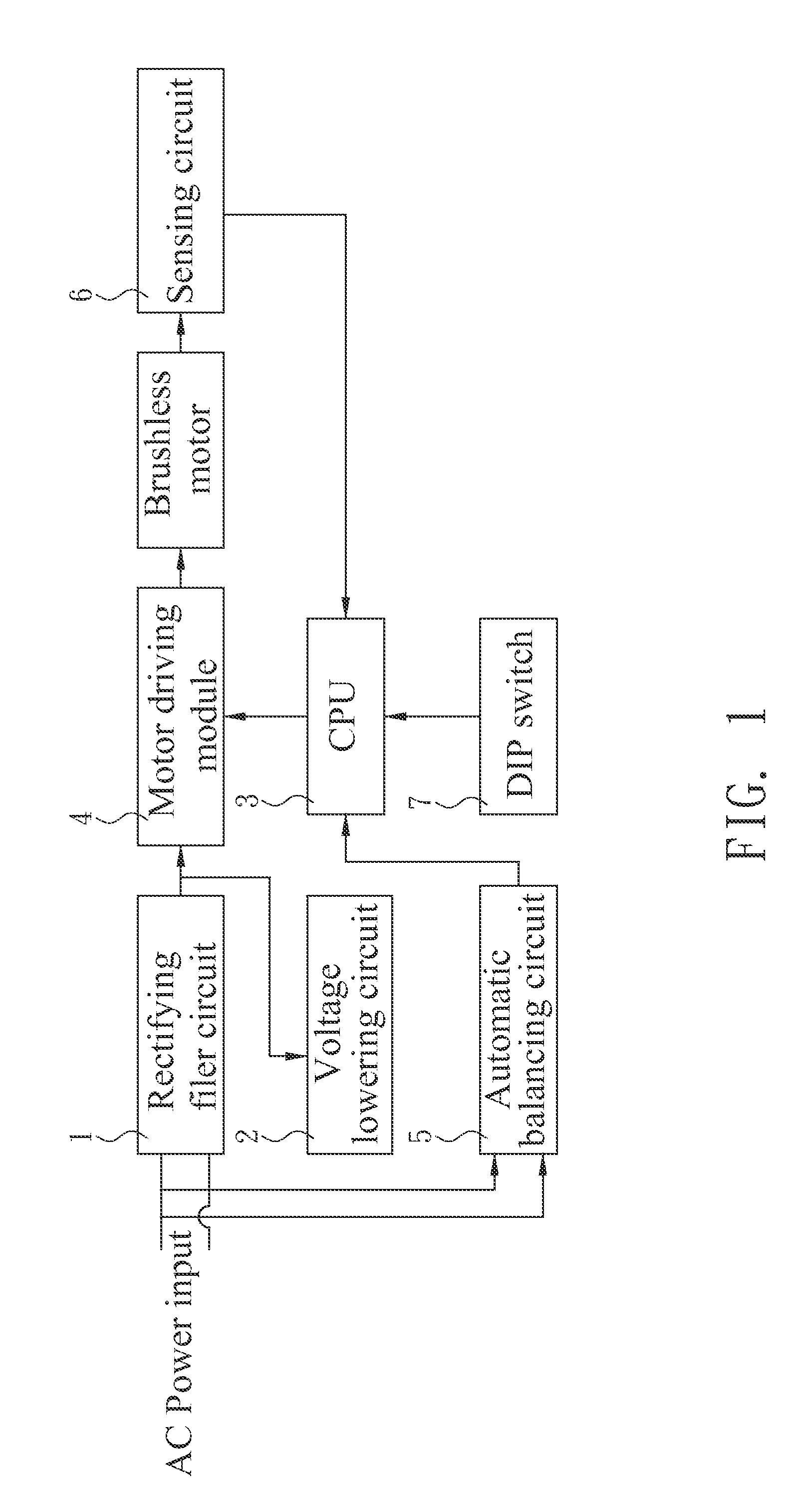

[0015]The preferred embodiment of the ceiling fan controller using a DIP switch to set a rotation speed is shown in FIG. 1. The controller in this embodiment includes: a rectifying filter circuit 1, a central processing unit (CPU) 3, a motor driving circuit 4, an automatic balancing circuit 5, and a sensing circuit 6.

[0016]The rectifying filter circuit 1 rectifies and filters AC power into DC power to provide the power for driving the DC non carbon brush motor. In this embodiment, the rectifying filter circuit 1 electrically connects to a voltage lowering circuit 2 to provide the power required by the system.

[0017]The CPU 3 is built in with a control routine to process input / output signals of the controller. The motor driving module 4 drives the DC non carbon brush motor of the ceilin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com