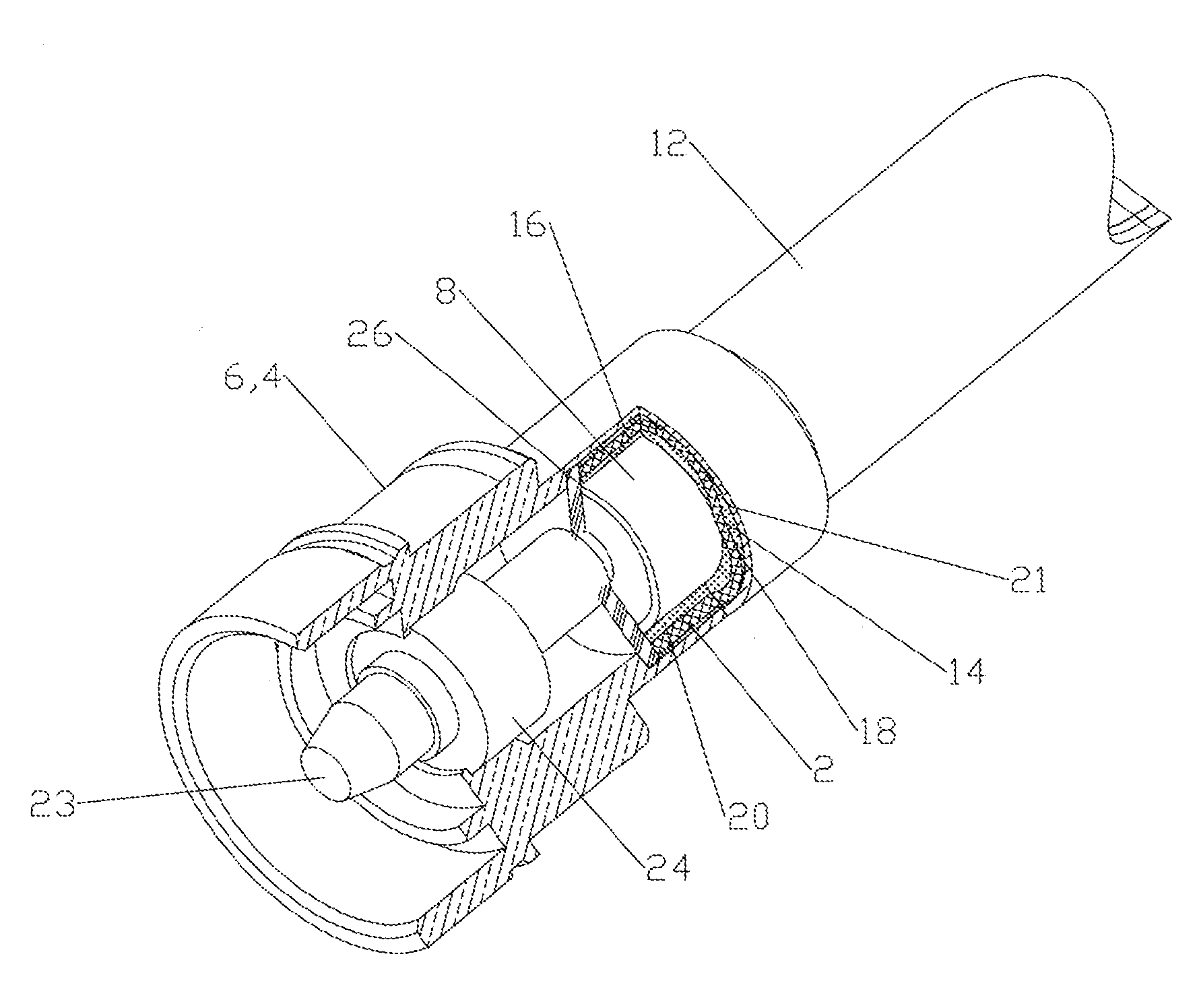

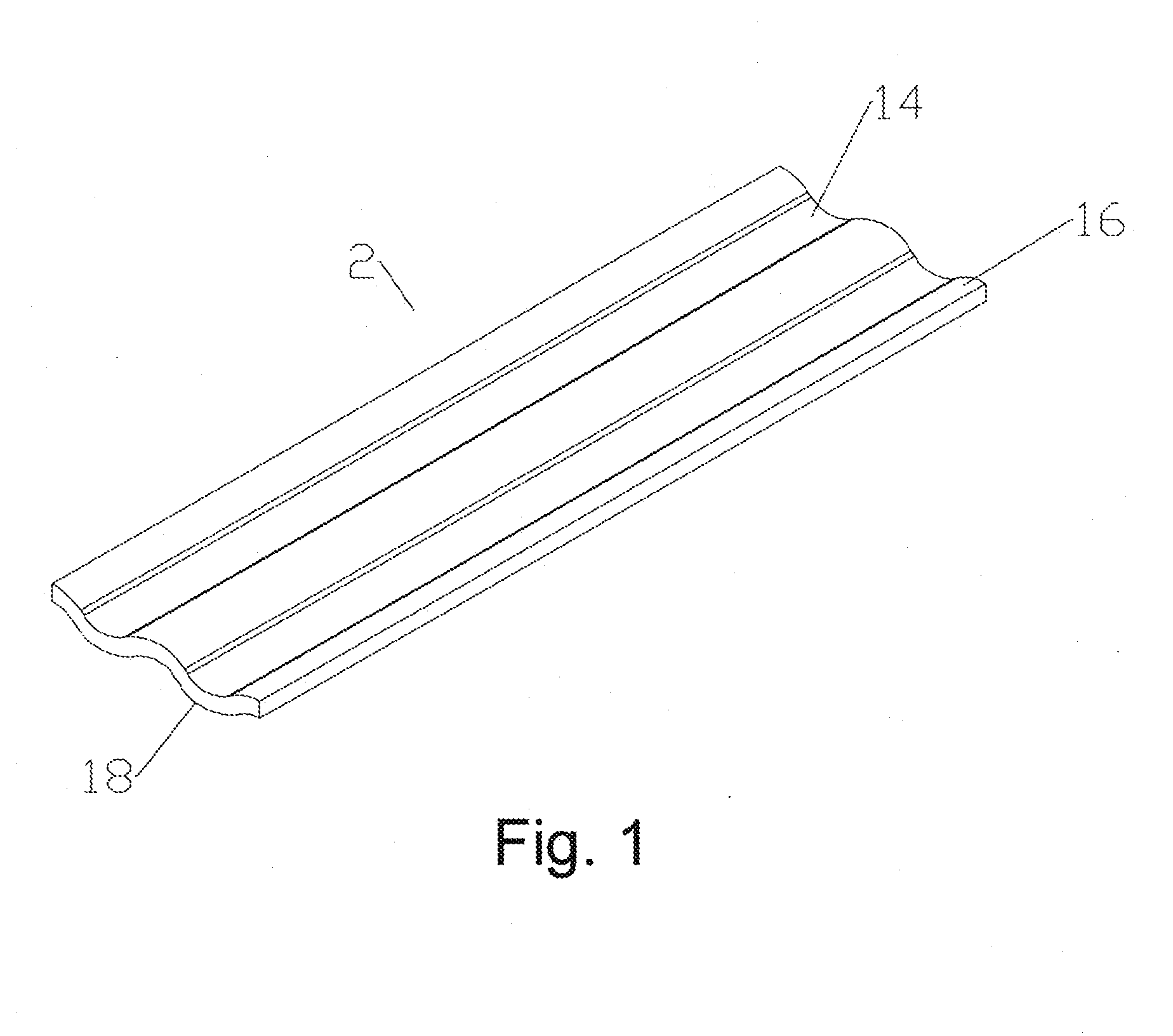

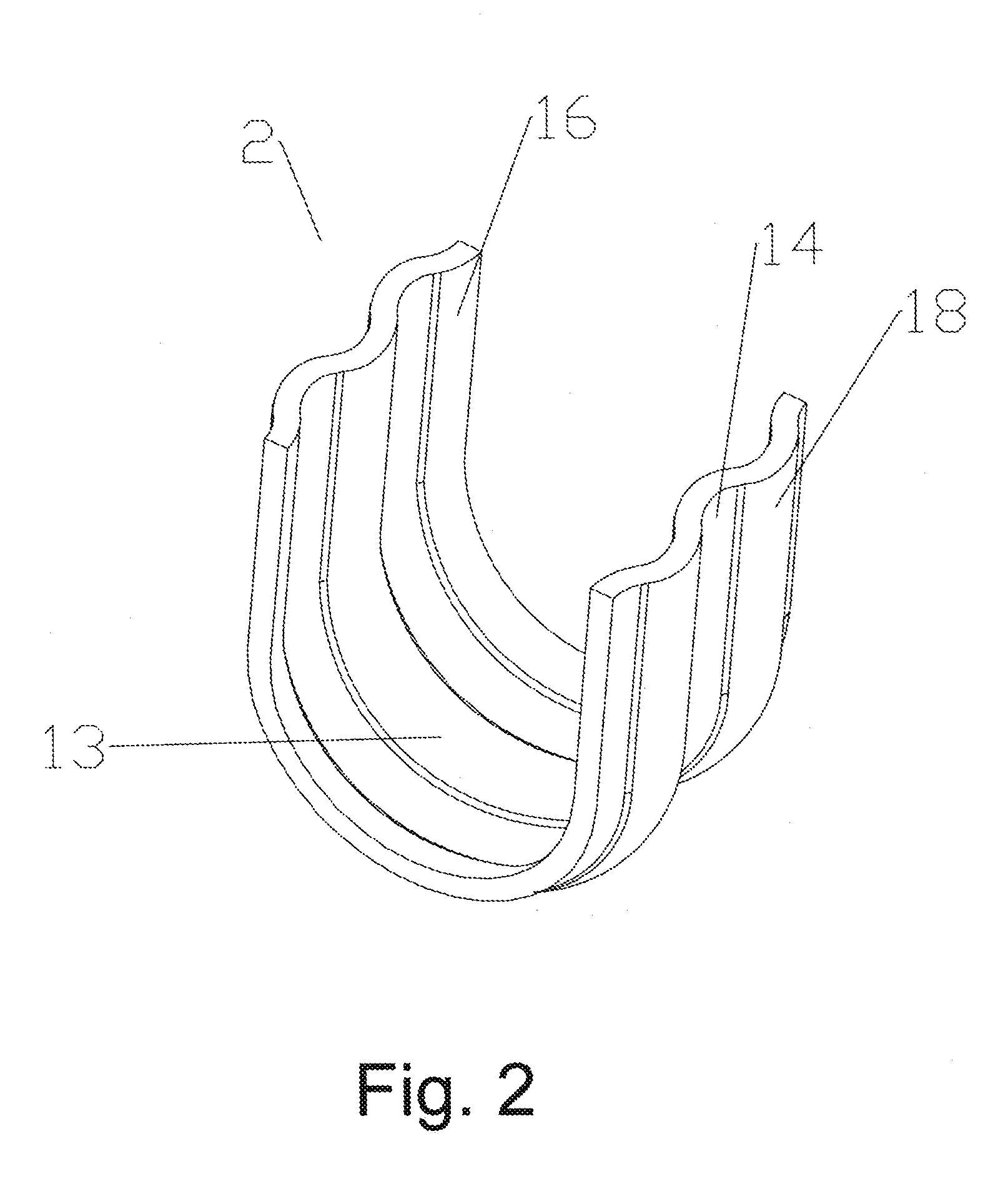

Corrugated Solder Pre-form and Method of Use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]The inventor has recognized that significant difficulties arise when attempting to solder a coaxial connector to a smooth sidewall outer conductor coaxial cable when the connector body and / or coaxial cable outer conductor are aluminum material.

[0028]The inventor's analysis indicates that, due to the speed of the aluminum oxide coating formation, if the aluminum material surfaces to be soldered are not coated with the flux immediately prior to initiation of heating to melt the solder pre-form, the quality of the resulting solder interconnection may be degraded. When the flux is heated as soldering is initiated, the flux volatizes, wetting and acid washing away the aluminum oxide coating likely present on the aluminum material surfaces, immediately prior to the melting of the solder pre-form to solder these surfaces together.

[0029]When utilizing the prior solder pre-forms, for example with a smooth connector side or multiple solder pre-form ring configuration, inventor's testing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com