Makeup composition comprising a black colour mixture of pigments

a technology of black colour and pigment mixture, applied in the field of make-up composition comprising a black colour mixture of pigments, can solve the problems of difficult reproducibility, significant problem in the development of novel pigments, and difficulty in economically advantageous straightaway use of pigment mixtures to produce this colour, etc., and achieve the effect of improving the visual

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Dispersion of the Subtractive Mixture

[0169]Dispersions were prepared comprising the subtractive mixture of black colour according to the formulae below (% by weight relative to the final mixture):

[0170]BLACK 1 Mixture

[0171]52% of an aluminium lake of the dye FD&C Blue No. 1 (CI 42090)

[0172]40% of an aluminium lake of the dye FD&C Yellow No. 5 (CI 19140)

[0173]8% of a calcium lake of the dye DC Red No. 7 (CI 15850)

[0174]BLACK 2 Mixture

[0175]31.2% of an aluminium lake of the dye FD&C Blue No. 1 (CI 42090)

[0176]52% of an aluminium lake of the dye FD&C Yellow No. 5 (CI 19140)

[0177]16.8% of a calcium lake of the dye DC Red No. 7 (CI 15850)

[0178]Each organic pigment constituting the BLACK 1 or BLACK 2 mixture was dispersed to 4% by weight in a transparent nail varnish base essentially consisting of a film-forming polymer such as nitrocellulose, at least one plasticizer and at least one rheology additive, in a solvent or mixture of solvents (butyl acetate and / or ethyl acetate).

[0179]The fin...

example 2

Calculation of the Luminance L* (CIELAB)

[0180]For the measurements of L*, the dispersions of subtractive mixture prepared in Example 1 were used.

[0181]Control compositions were prepared separately that comprise 4% by weight of an intrinsically black pigment (black iron oxide or carbon black) dispersed in the same nail varnish base as in Example 1.

[0182]A film having a thickness of 300 μm was formed by spreading a composition above onto a contrast card, using a spreader bar.

[0183]The film was dried on the contrast cards, before the colorimetric measurement is carried out with an MA 98 spectrocolorimeter from the company X Rite.

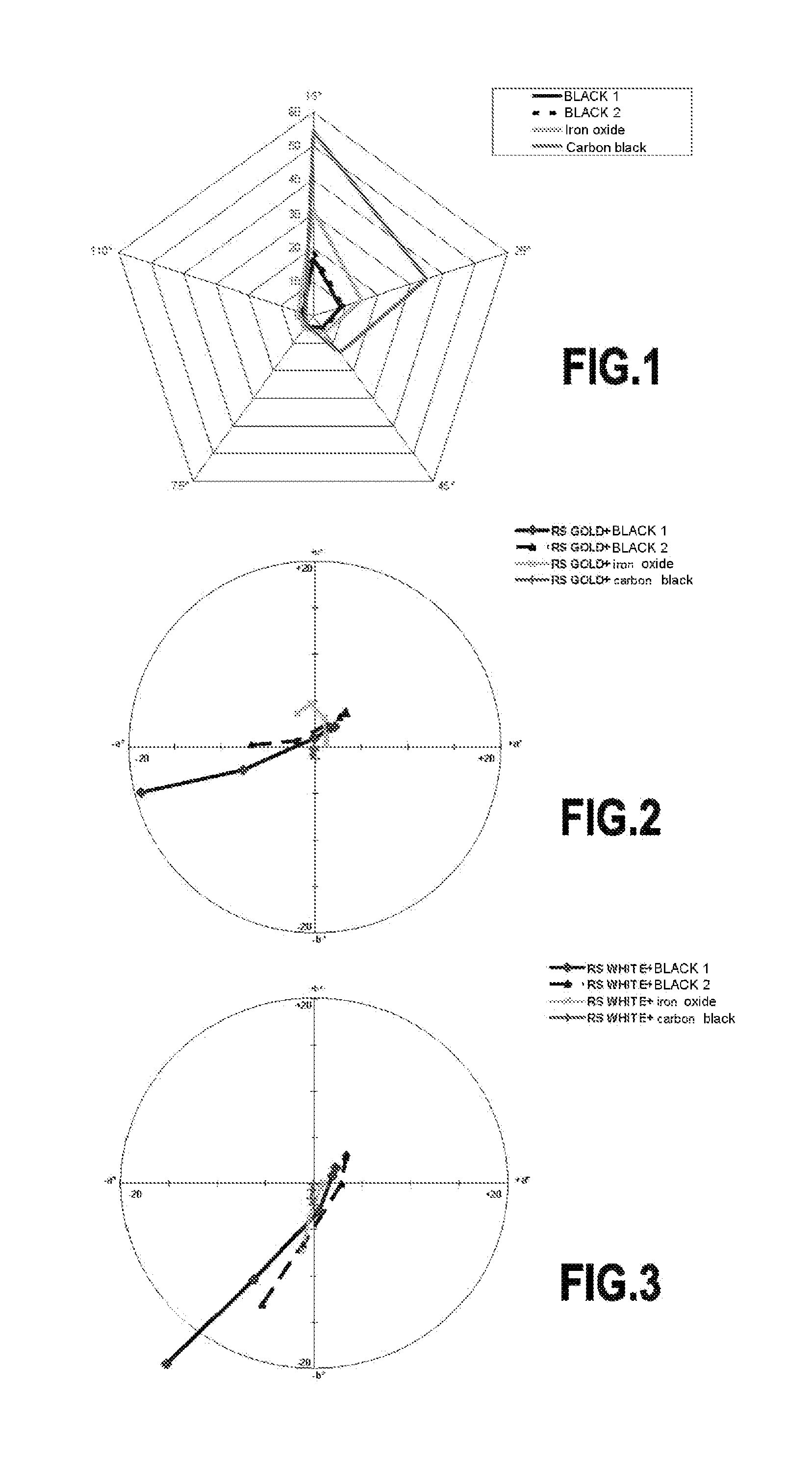

[0184]The luminance values L* were obtained under a 10° D65 illuminant. A diode array captured reflection values at five additional angles (15°, 25°, 45°, 75°, 110°) measured relative to the specular light. The luminance values L* were reported in FIG. 1, which included an L* axis for each of the five angles of reflection.

[0185]The values of L*(15°) measured ar...

example 3

Measurement of the Nacreous Effect (SRR GLOSS)

[0187]3.1 Nacreous Effect Produced by a White Nacre Having a “Gold” Sheen

[0188]The visual effect exceptionally produced by the combination, in a composition, of an “optical effect” material and of the subtractive mixture of black colour of the invention was demonstrated.

[0189]A white nacre having a “gold” sheen (Reflecks Dimension Sparkling Gold, BASF) at a content of 2% by weight was added to a dispersion from Example 1 comprising the subtractive mixture BLACK 1 or BLACK 2, and also to the control compositions from Example 2. The values of L* and of the components a* and b* (Table 2) were measured on a dry film according to the same method as in the preceding example.

TABLE 2RS GOLD +RS GOLD +RS GOLD +black ironRS GOLD +BLACK 1BLACK 2oxidecarbon blacka*b*a*b*a*b*a*b*15°−18.59−4.89−6.770.21−1.773.650.04−1.2825°−7.66−2.5−1.870.66−0.514.62−0.27−0.8245°−0.080.92.673.20.963.16−0.12−0.2175°1.712.053.323.831.181.23−0.050110° 2.152.183.383.581.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com