Device for removing fluids from vials

a technology for fluid removal and vials, which is applied in the field of fluid removal devices, can solve the problems of similar problems posed in other pharmaceutical or chemical systems comprising two or more components, gas, in particular oxygen from the air, can diffuse through the walls of the applicator or through seals, chemically modify the content, etc., and achieve the effect of reducing the dead volum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

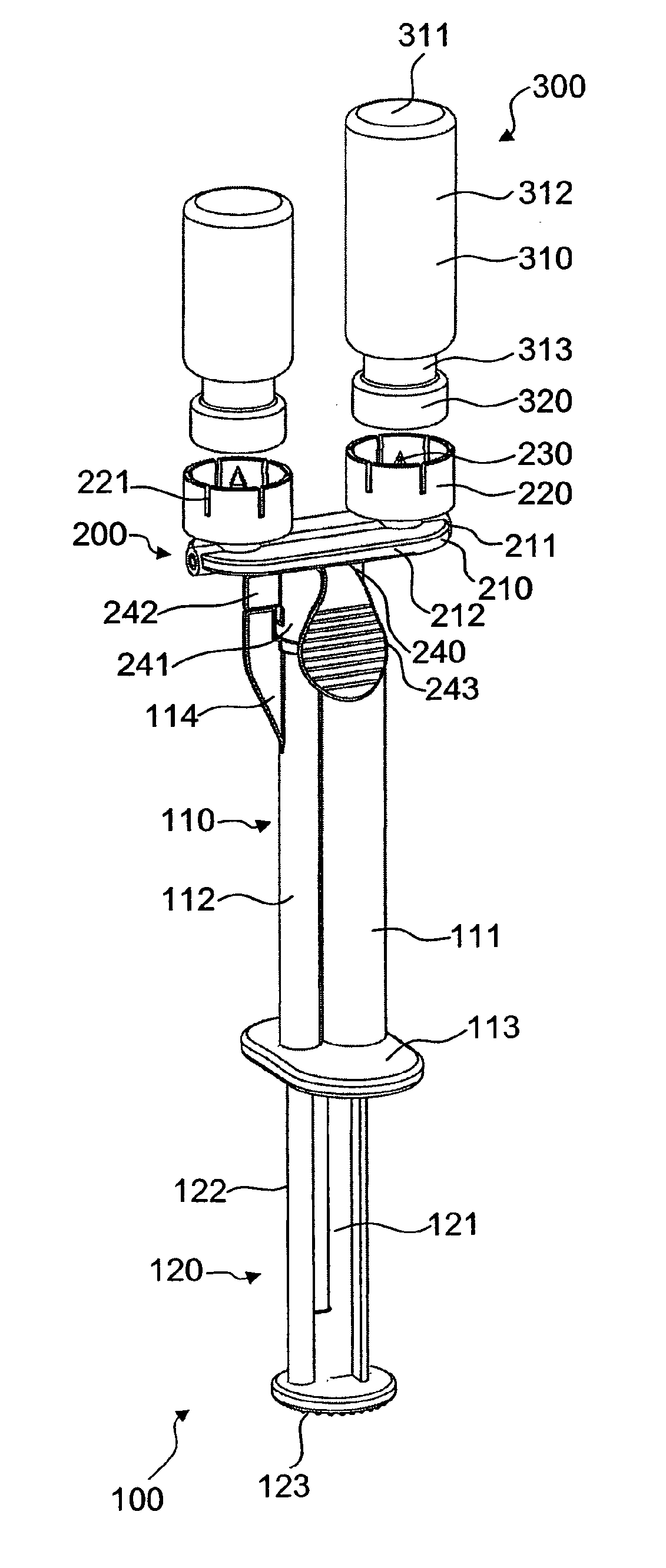

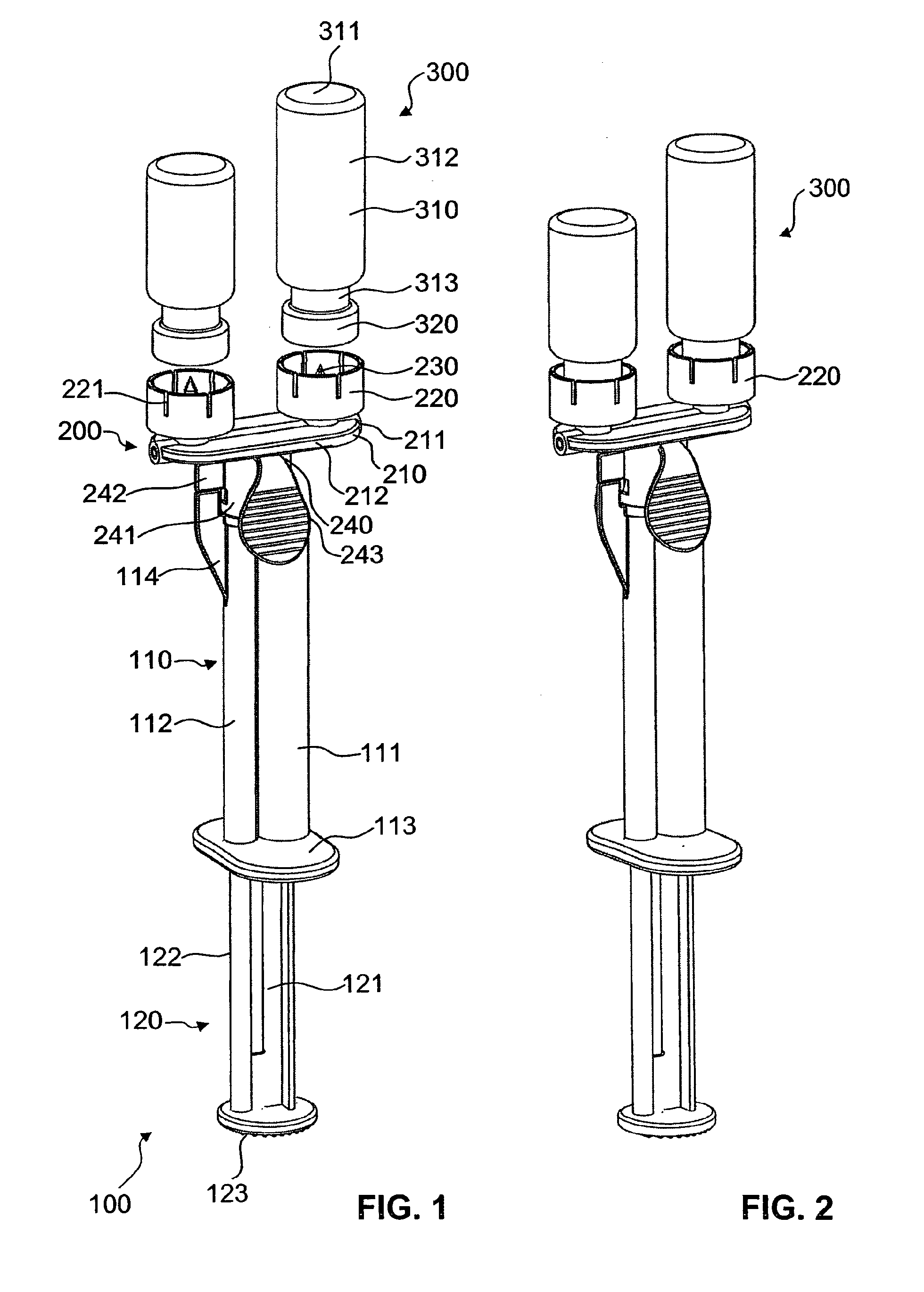

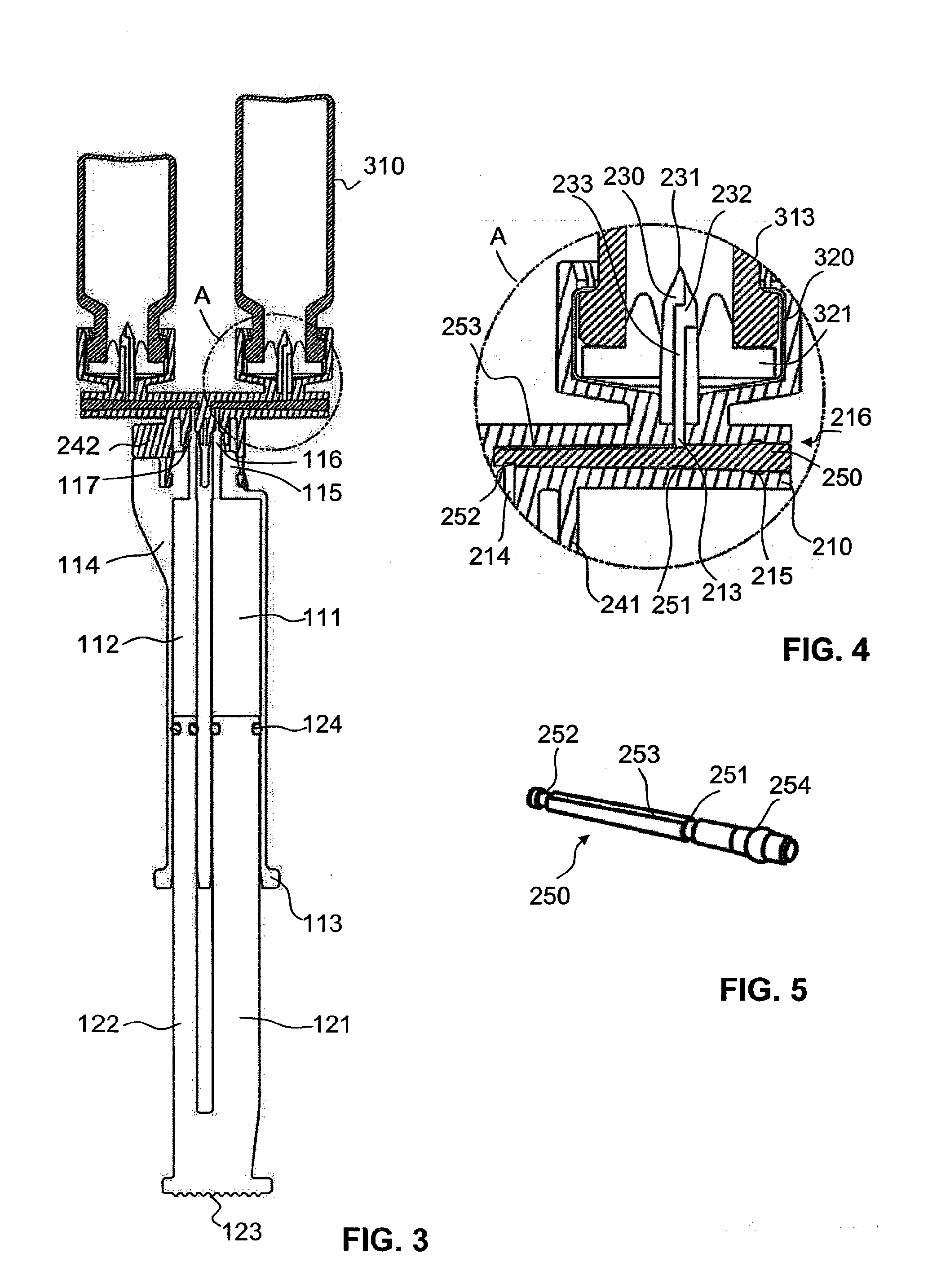

[0045]In FIGS. 1 to 5 a first exemplary embodiment of a filling device in accordance with the invention is illustrated. The filling device 200 has a basic body 210 which is of an elongated, essentially disk-shaped form. Formed on the basic body 210 is a central, cylindrical thickening 211, to which the two halves of a flat carrier plate 212 are connected. With its cylindrical axis the thickening 211 defines a longitudinal direction.

[0046]Along this longitudinal direction from each of the two ends of the cylindrical thickening 211 a blind-type longitudinal bore is formed, which each ends just before the middle of the thickening (FIGS. 3 and 4). Each of these bores widens slightly conically towards its open end and forms a fluid channel. The two bores are collinear to each other, i.e. they are on the same axis one behind the other.

[0047]Toward the upper side of the basic body 210 in the area of the thickening there is an inlet opening 213 for each of the bores (FIG. 4). This inlet ope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com