Hybrid Cooling System

a hybrid cooling and cooling system technology, applied in the direction of trickle coolers, steam/vapor condensers, lighting and heating apparatus, etc., can solve the problems of low water-saving ability, high investment cost of systems, limited application, etc., and achieve the effect of quick enhancement of cooling capacity and improved operation flexibility of hybrid cooling systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

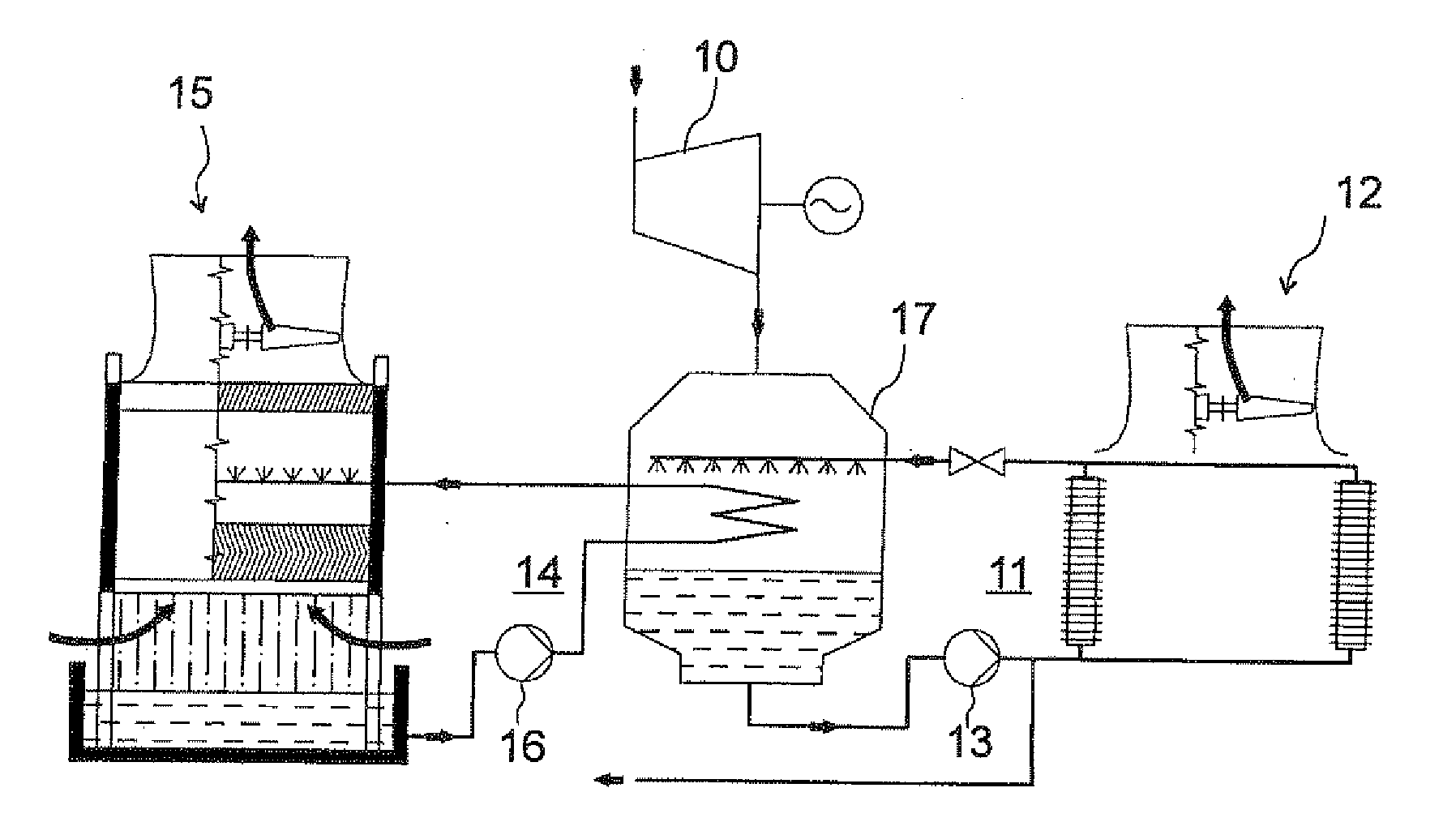

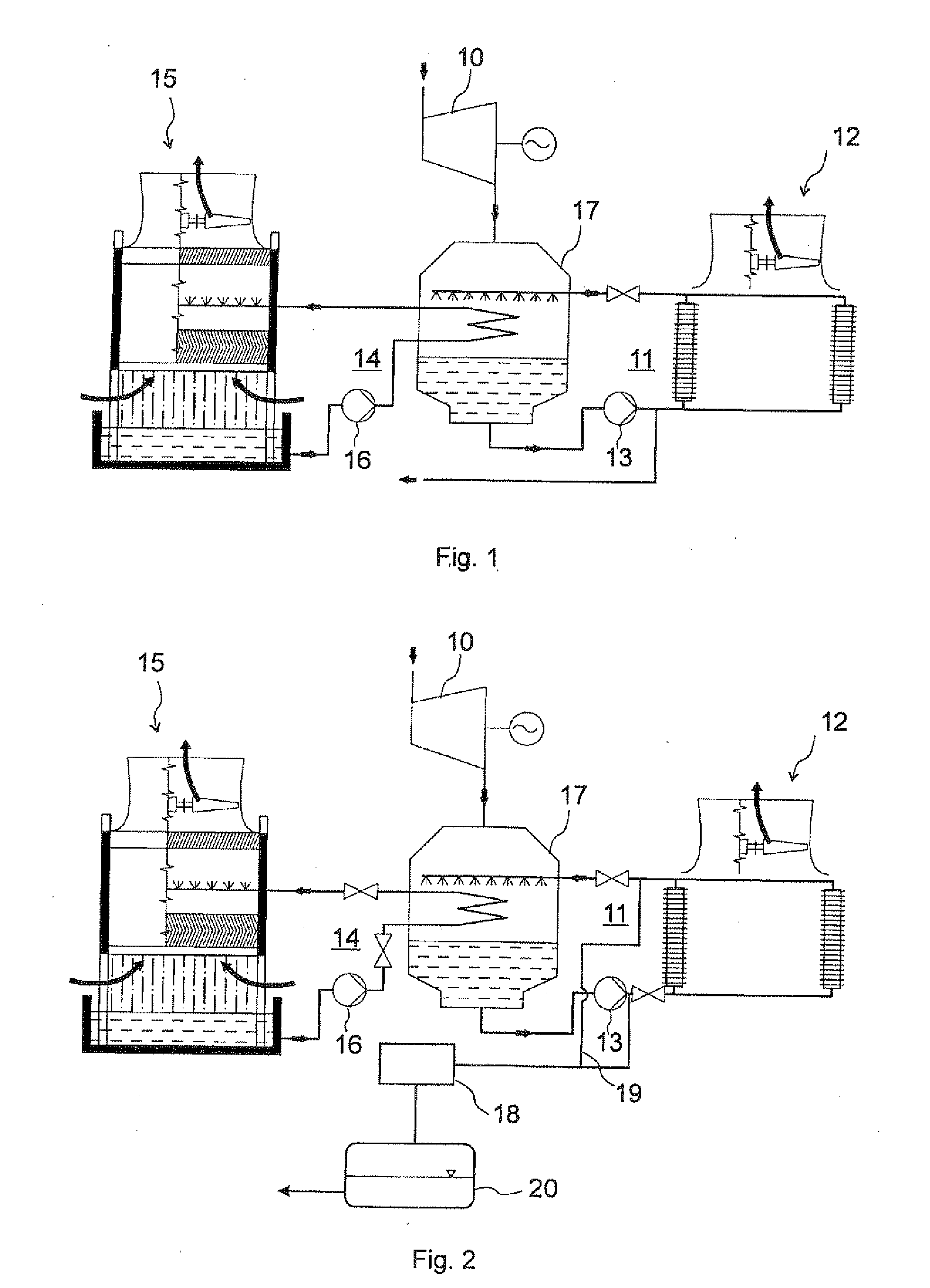

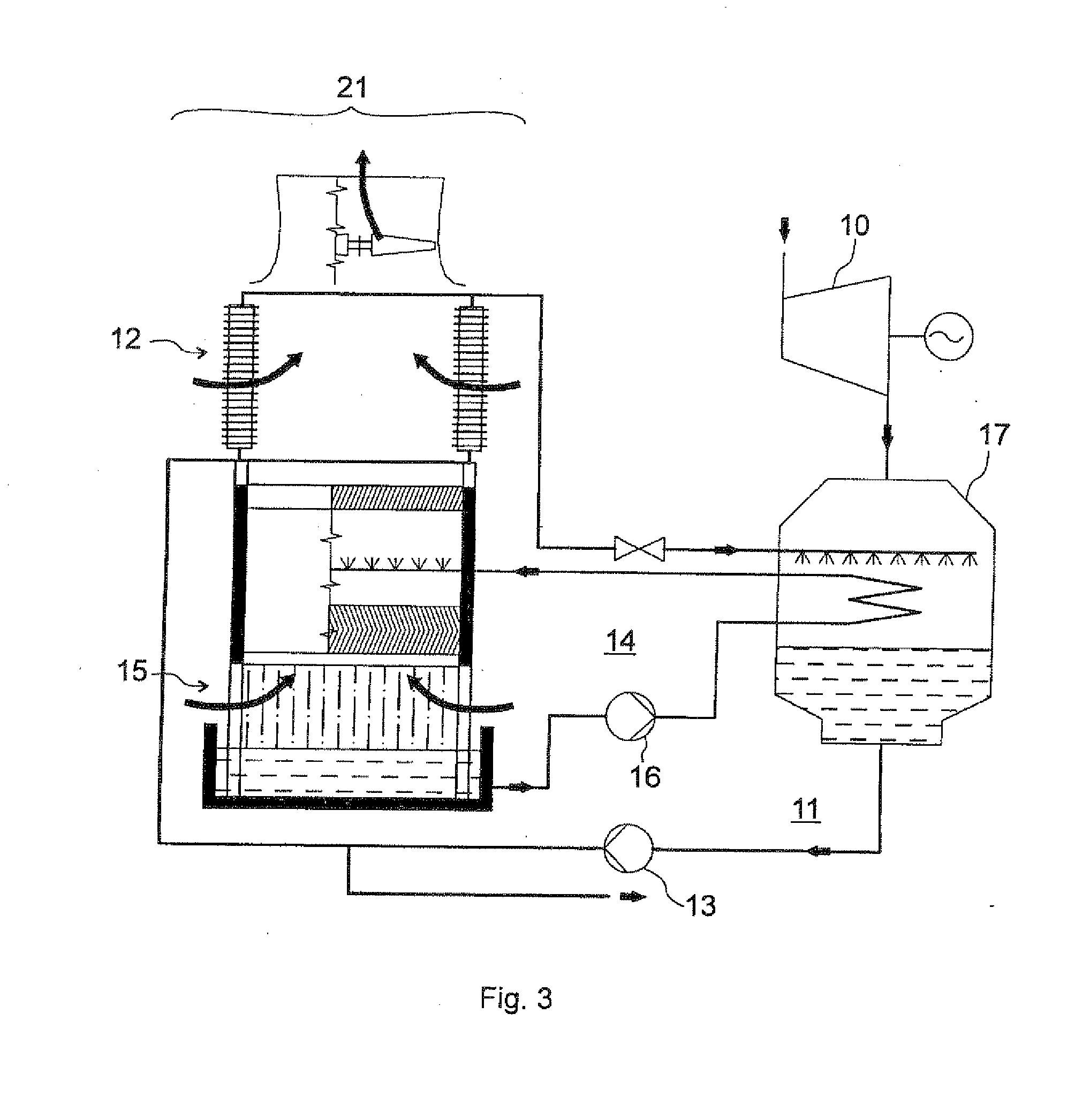

[0005]The object of our invention is to provide a dry / wet, i.e. hybrid cooling system which is exempt from the disadvantages of prior art solutions. The object of the invention is especially to create a hybrid cooling system, which combines the advantages of dry and wet cooling, while entailing no extra maintenance requirements. It is a further object to make use of other benefits offered by the combined use of dry and wet cooling, as well as the creation of a hybrid cooling system in which the proportion of dry and wet sections can be altered arbitrarily depending on the environmental parameters and actual circumstances.

[0006]Accordingly, the invention is a hybrid cooling system defined in claim 1. Preferred embodiments of the invention are defined in the dependent claims.

[0007]An important idea of the solution according to the invention is that instead of a single water circuit, separate water circuits are to be applied for the wet cooling and the dry cooling. As a preferred embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com