Coffee Treatment Method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

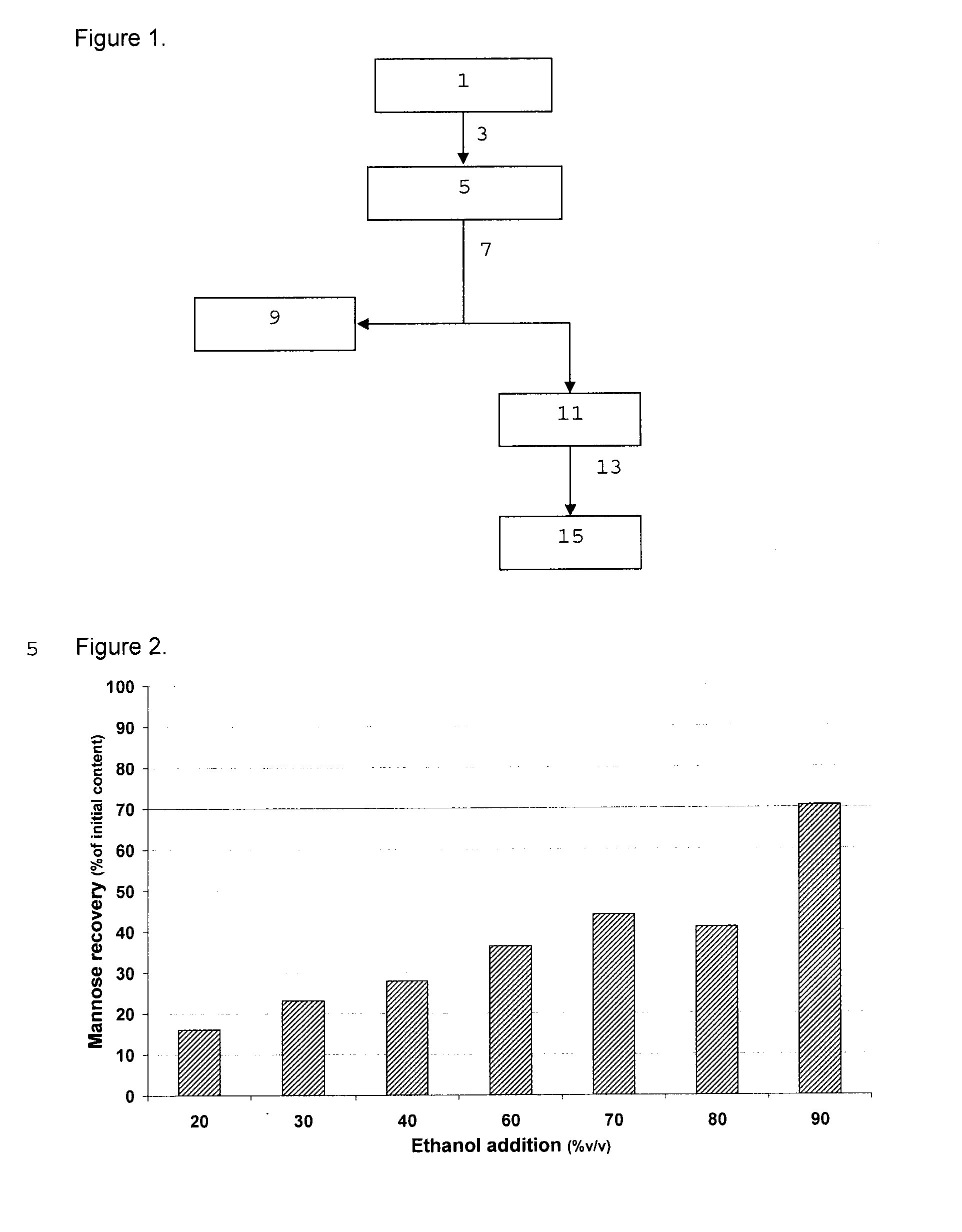

[0053]An amount of coffee extraction residue material was mixed with water to form a slurry (10% by weight solids) and passed into a plug flow reactor. The slurry was heated to 230° C. for 6 minutes. After this thermal hydrolysis step, the solids were extracted (by centrifuging) from the slurry and discarded to leave a liquid hydrolysate 1 (see the flow chart in FIG. 1).

[0054]The liquid hydrolysate 1 was then mixed in a mixing step 3 with sufficient ethanol (food-grade) to form an 80% v / v ethanolic solution 5. The mixing step 3 was performed on a continuous liquid hydrolysate 1 stream passing from the plug flow reactor.

[0055]The ethanolic solution 5 was allowed to cool to encourage the MOS fraction to precipitate out. After precipitation the suspension was centrifuged in a separation step 7. The separation step 7 produced a supernatant 9 which was discarded and a precipitate 11.

[0056]The precipitate 11 was then re-dissolved in minimal water and freeze-dried in a finishing step 13. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap