Packaging to improve shelflife of insulation products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

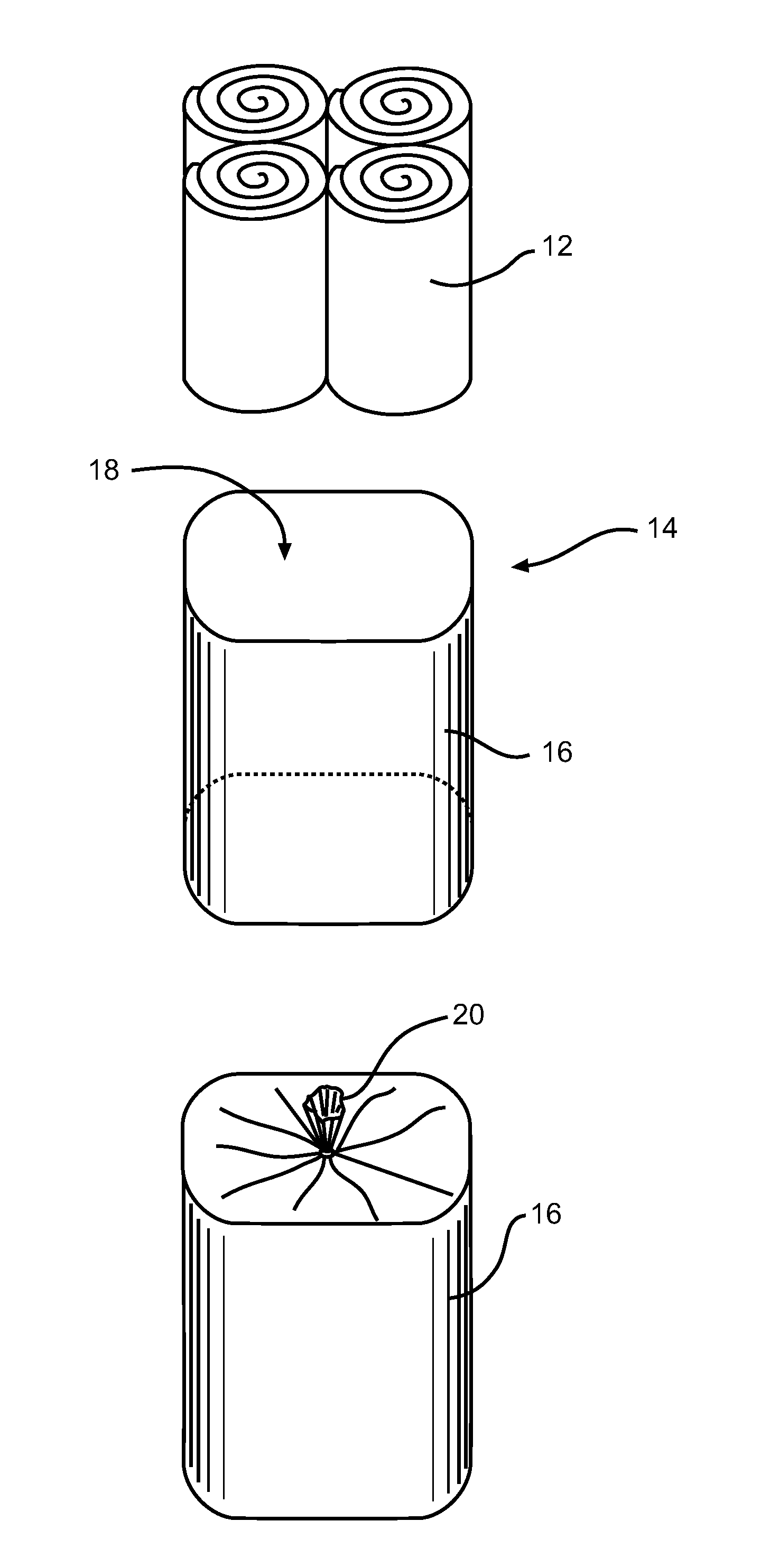

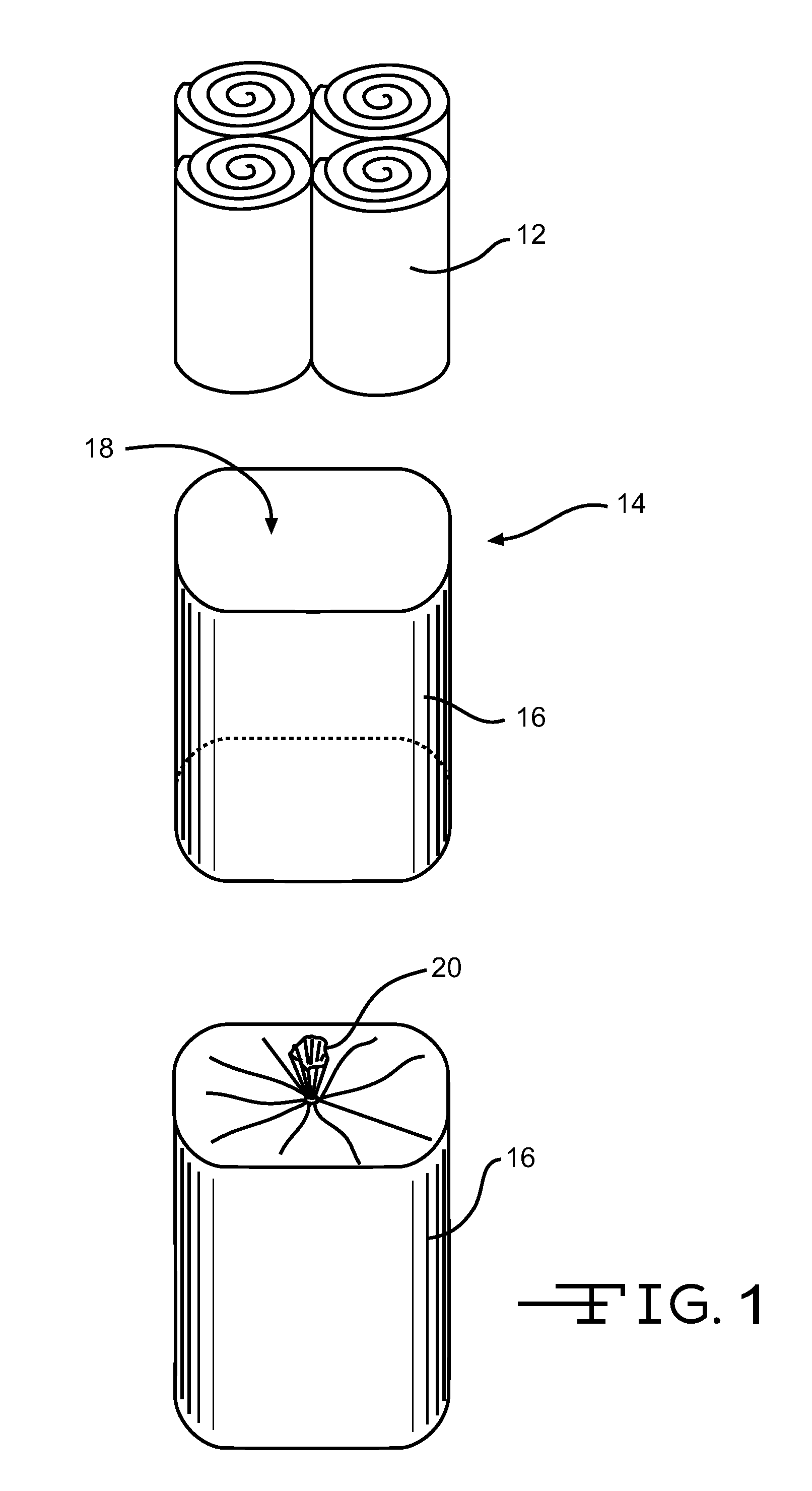

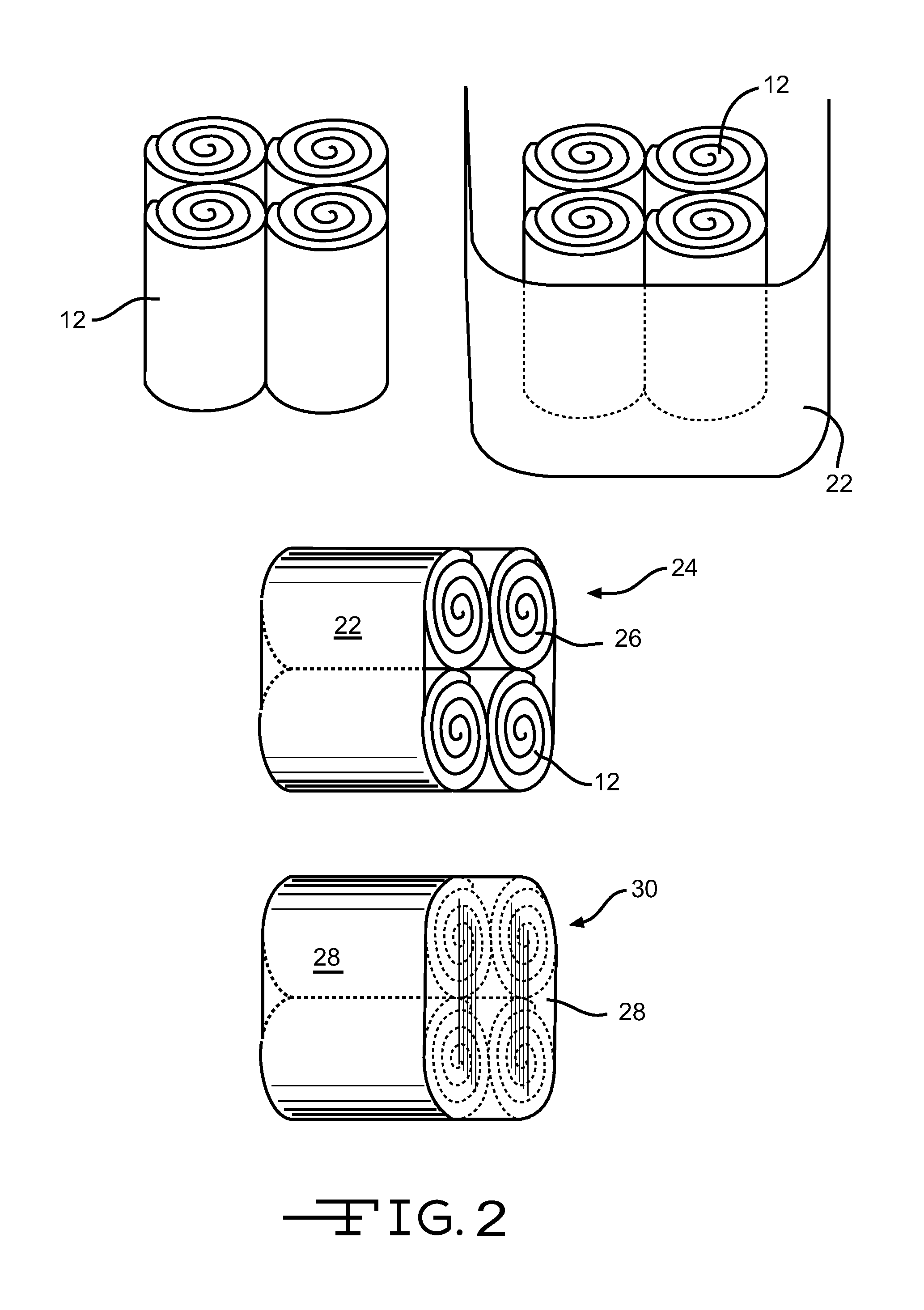

Image

Examples

examples 1-14

[0073]Examples 1 to 14 herein are incorporated from Examples 1-14, including tables 4-33 that appear in U.S. patent application Ser. No. 13 / 037,725 titled “INSULATIVE PRODUCTS HAVING BIO-BASED BINDERS” filed Mar. 1, 2011, already incorporated herein.

example 15

[0074]Various packaging materials are obtained having the physical properties listed in Table 34.

TABLE 34Representative Packaging Material PropertiesSample 1Sample 2Sample 3Sample 4(Bag)(Bag)(DSW film)(DSW film)nominal2.02.01.51.5thickness (mils)No. of layers1132compositionLDPELDPE / PPLDPEPEcopolymerpermeance0.250.30.150.3g*in / hr*ft2*in Hgelasticity (%)700%800%600%550%tensile / elongation4500500070007500(psi)tear (g / mil)875900600575Coeff. of Friction0.350.41.52.0haze (%) 14% 16% 6% 7%

example 16

[0075]Flexible duct media (FDM) is a type of fibrous insulation that is often used around flexible conduit or tubing. It is generally available in rolls designated with R values 4.2, 6 or 8 and having nominal thickness of 1.25, 2, and 2.25 inches, respectively. FDM was produced with a bio-based binder according to the invention in R6 thicknesses (nominally 2 inches) and placed in various types of packaging for testing. The comparison points were the recoveries achieved after storage at ambient conditions for 7 days (“ambient x7d”). The experimental conditions tested include accelerated temperature and humidity tests as well as variations in time (x21 days vs. x7 days). For example, the condition labeled “73 / 92” indicates a temperature of 73F and relative humidity (RH) of 92%; and the condition labeled “73 / 92-92 / 50” indicates a cycled temperature and humidity profile simulating day and night in a humid area of the country; i.e. 73F with 92% RH by night and 92F with 50% RH by day. Pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com