L-profile shaped element, the use of same and a method for installing same

a technology of l-profile and shaped elements, which is applied in the field of l-profile shaped elements, can solve the problems of seldom enduring intensive wear and use, easy loosing, etc., and achieve the effect of easy manufacturing and quick

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

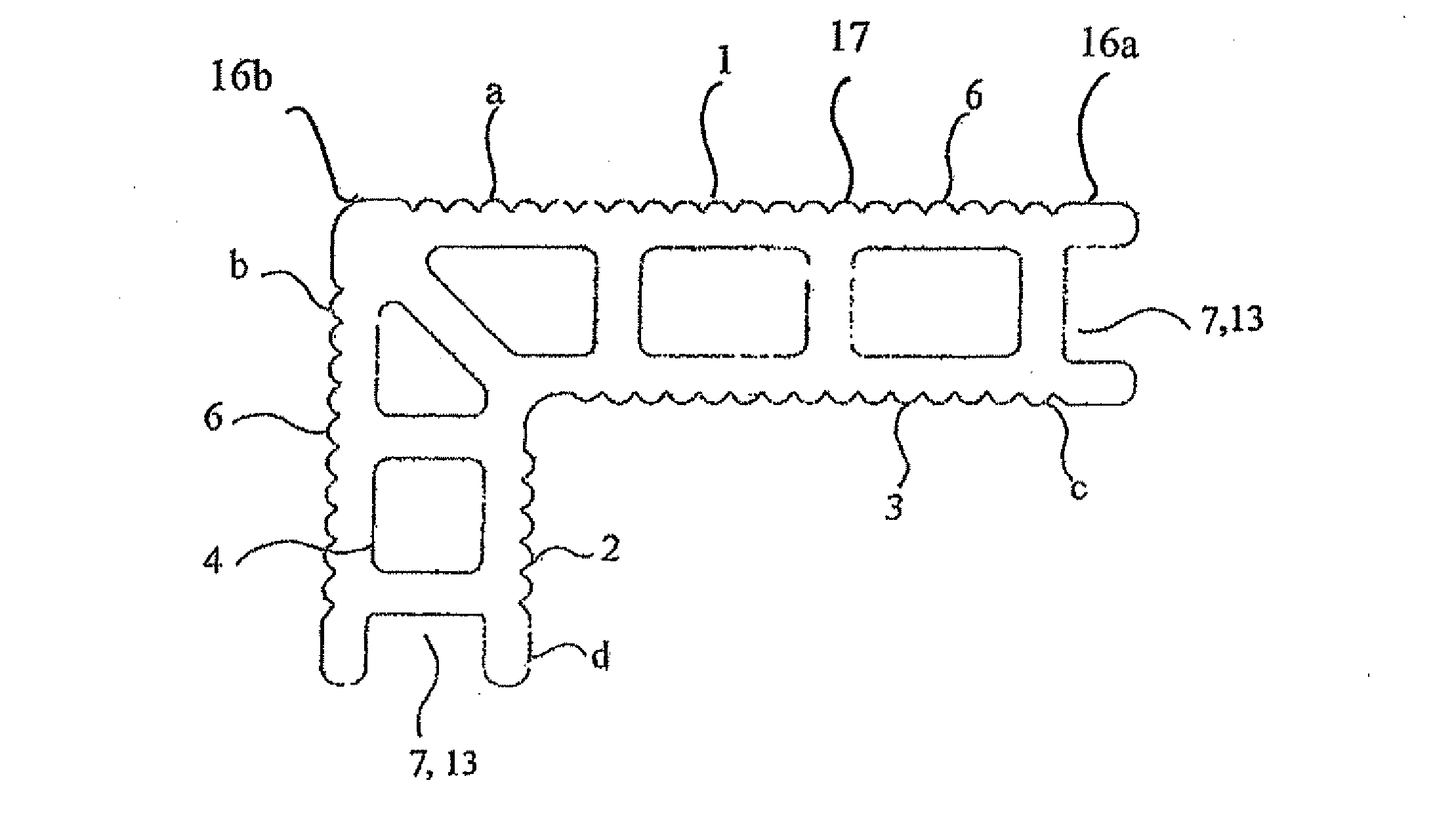

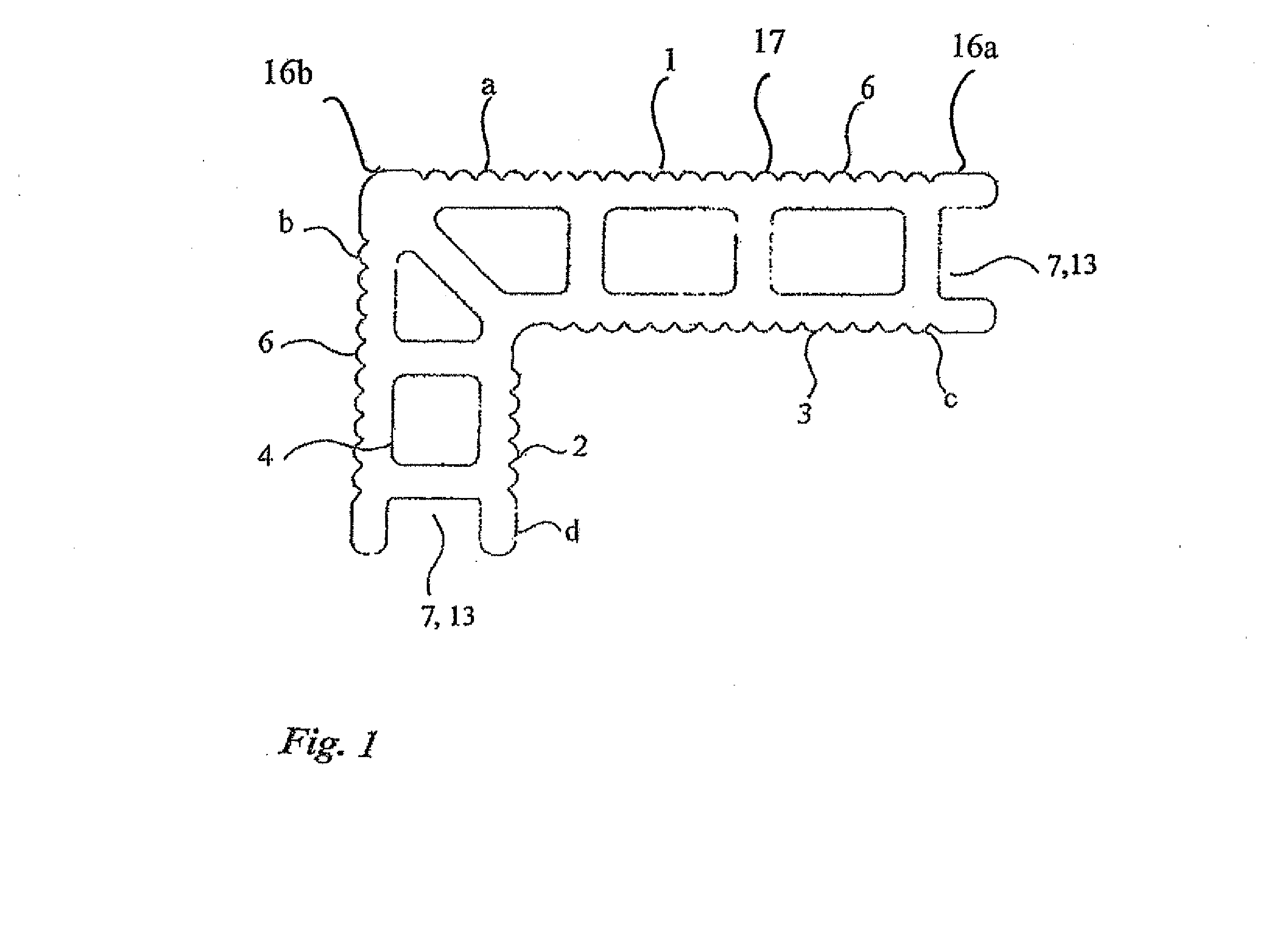

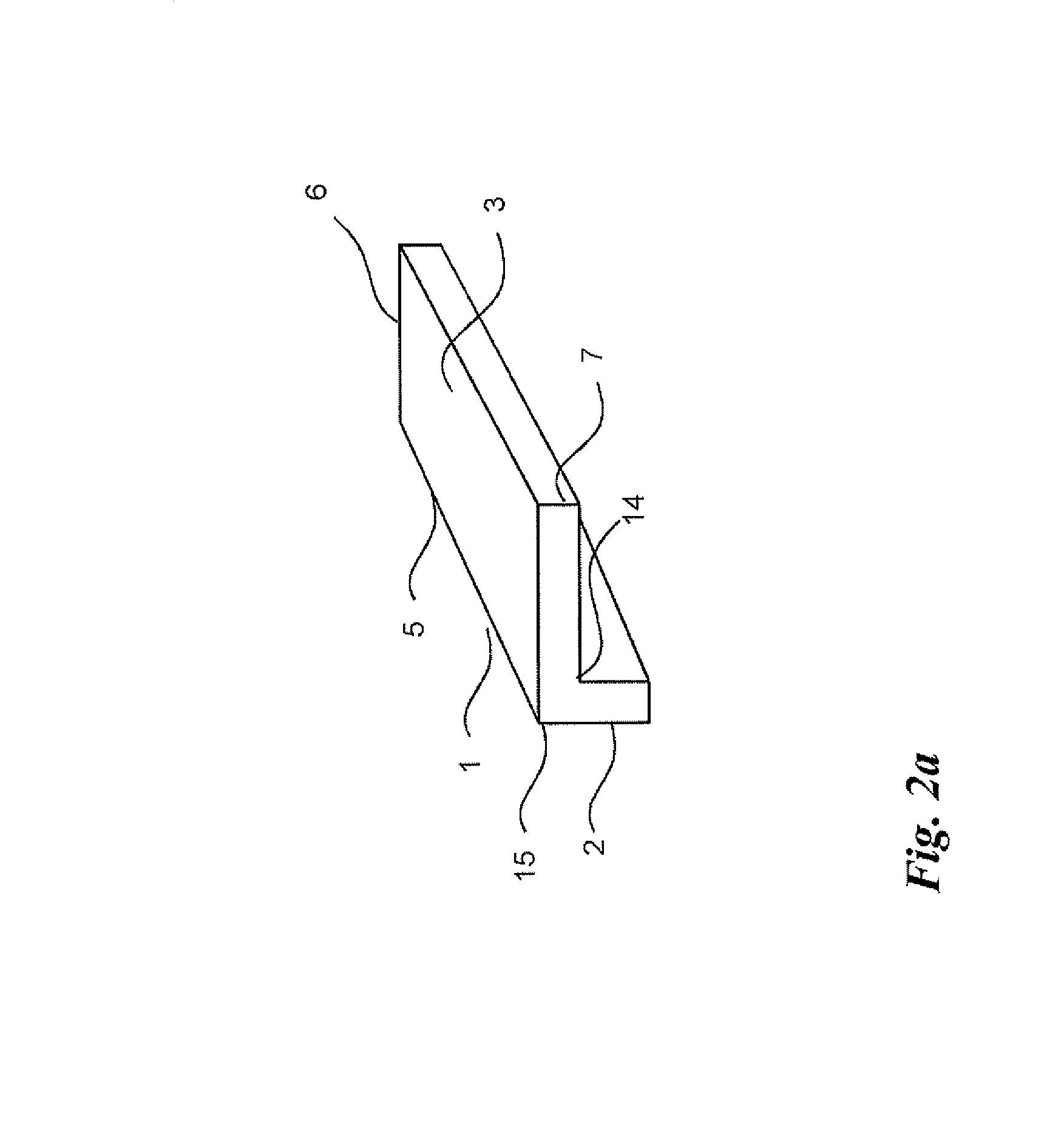

[0064]The L-profile shaped element 1 illustrated in FIGS. 1 and 2a was formed from a wood-plastic composite material. The wood-plastic composite material was mainly formed from adhesive laminate waste. Polypropylene had been added to the adhesive laminate waste. The L-profile shaped element was formed as a monolithic piece by extrusion.

[0065]The L-profile shaped element 1 according to FIGS. 1 and 2a includes a first 2 and a second 3 leg, wherein the legs are arranged to have different widths 6 but the same thicknesses 7. The thickness 7 of the legs 2 and 3 is 28 mm in this embodiment. In this embodiment the width of the outer surface b of the leg in the first leg 2 is 68 mm and the width of the inner surface d is 40 mm. The width of the outer surface a of the leg in the second leg 3 is 110 mm and the width of the inner surface c is 82 mm. The length 5 of the L-profile shaped element 1 may vary depending on the purpose of use of the element.

[0066]An interior angle 14 and an exterior ...

example 2

[0072]FIG. 3 illustrates a stair structure formed from the L-profile shaped elements 1 according to Example 1.

[0073]The L-profile shaped elements 1 according to Example 1 are fitted in predetermined positions, in this case alternately both ways around in order to achieve an optimum rise and optimum run for the steps of the stair structure of this embodiment. The L-profile shaped element 1 forms together with another L-profile shaped element 1 the rise part 11 of the step and the tread 12.

[0074]Each L-profile shaped element is arranged to be joined from at least one thicknesswise end 7 of the leg to at least one thicknesswise end of the leg of another L-profile shaped element.

[0075]The joints between the elements are provided to the middle of the tread 12 or the rise part 11.

example 3

[0076]FIG. 4 illustrates a stair structure formed from the L-profile shaped elements 1 according to Example 1.

[0077]The L-profile shaped elements 1 according to Example 1 are fitted in predetermined positions, in this case alternately both ways around in order to achieve the optimum rise and optimum run for the steps of the stair structure of this embodiment. The L-profile shaped element 1 forms together with another L-profile shaped element 1 the rise part 11 of the step and the tread 12.

[0078]Each L-profile shaped element is arranged to be joined from at least one thicknesswise end of the leg to at least one thicknesswise end of the leg of another L-profile shaped element.

[0079]The joints between the elements are provided to the middle of the tread 12 or the rise part 11.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com