Display shelf with adjustable divider walls

a technology of divider walls and shelves, applied in the field of shelving systems, can solve the problems of elongating the divider wall, and reducing the efficiency of employees tasked with reconfiguring the channel width, etc., to achieve the effect of effectively resisting lateral loads, increasing the stiffness of the divider wall, and reversed engagement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

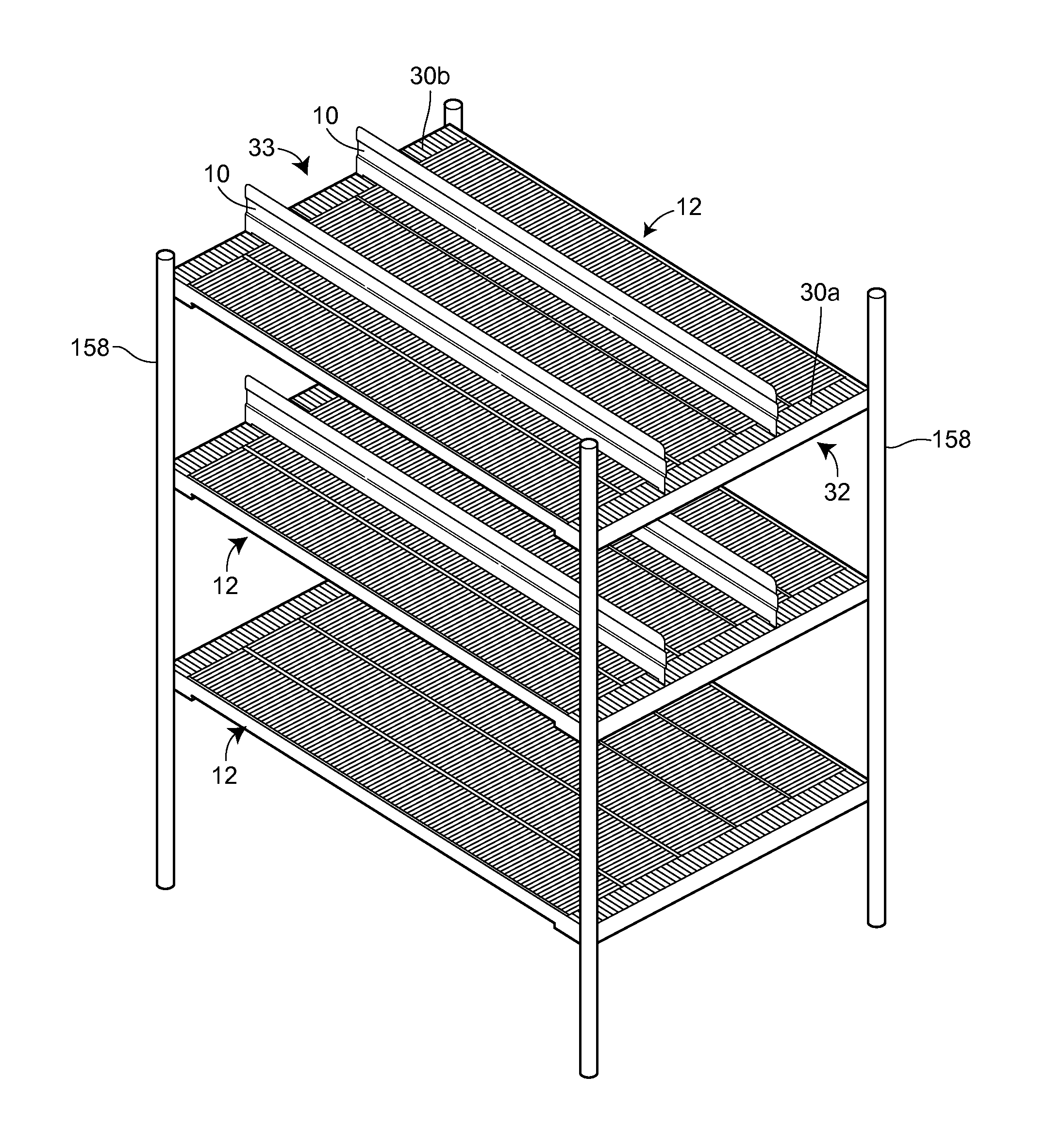

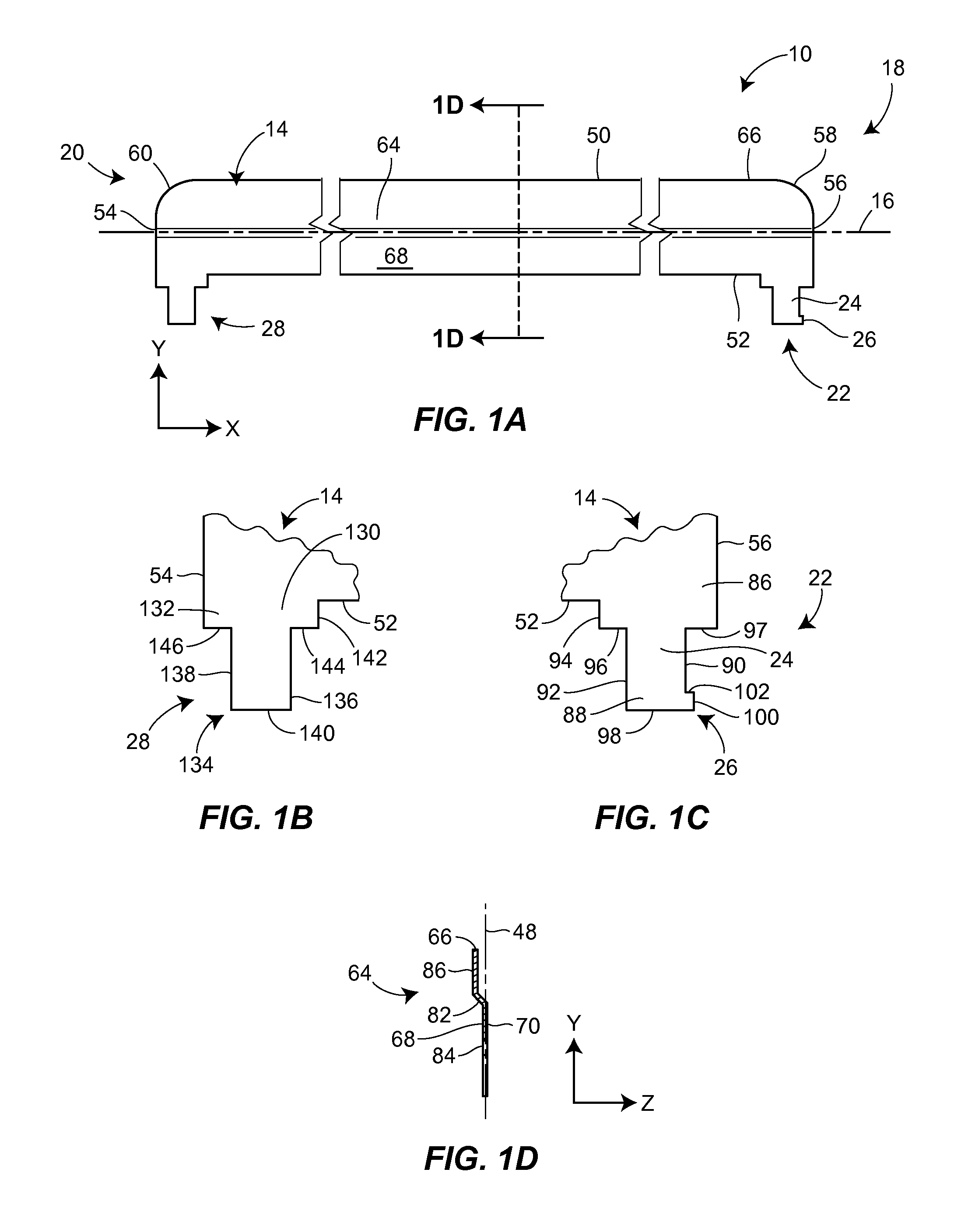

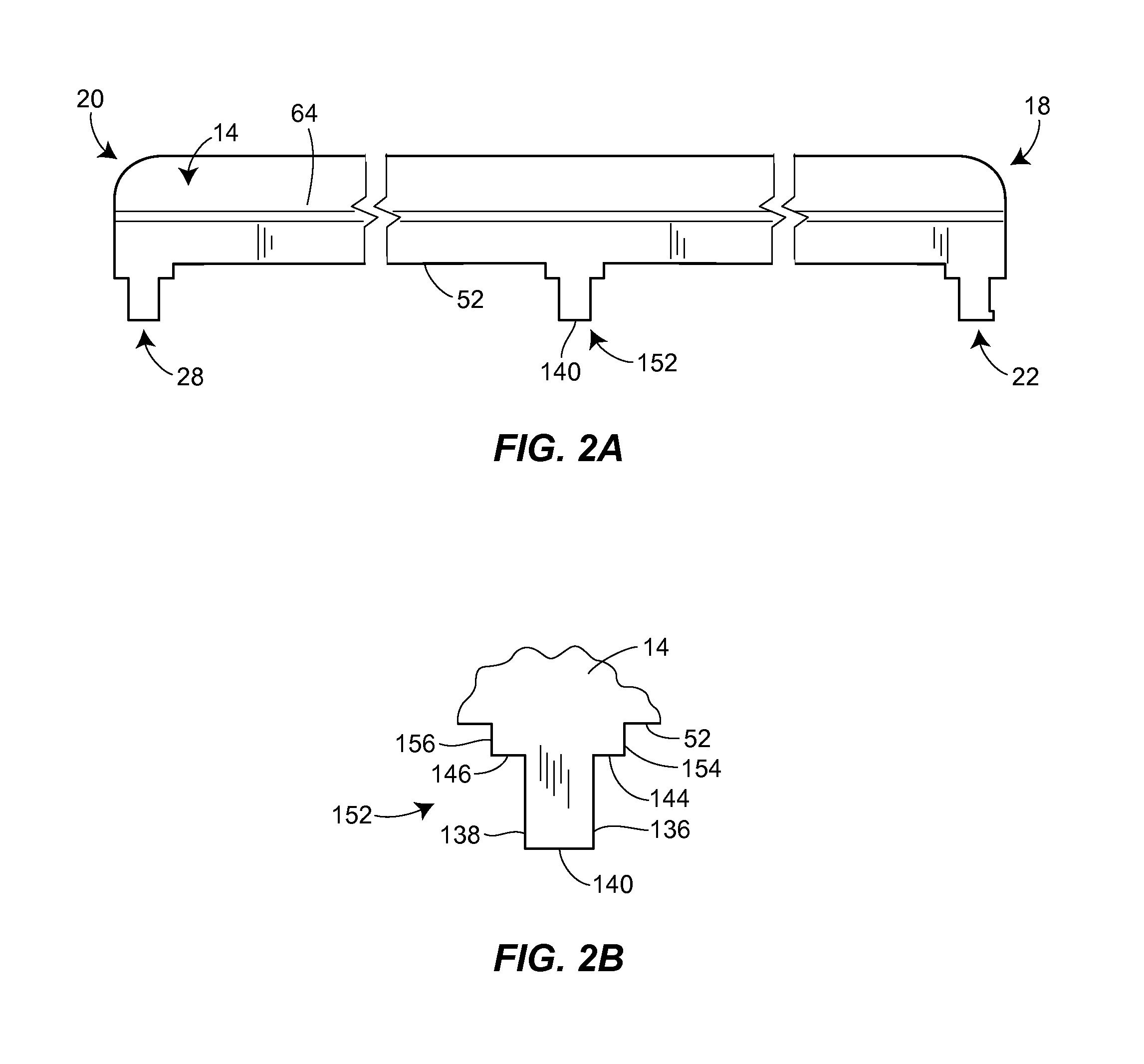

[0048]As illustrated in FIG. 1A, a divider wall 10 for use with a gravity-fed shelf assembly 12 includes an elongate wall portion 14 extending along a longitudinal axis 16, the wall portion 14 having a first end 18 and a second end 20. The divider wall 10 also includes a first front leg 22 extending from the wall portion 14 adjacent the first end 18, the first front leg 22 extending normal to the longitudinal axis 16 of the wall portion 14, the first front leg 22 having a body portion 24 and an engagement protrusion 26 extending from the body portion 24, the engagement protrusion 26 extending in a direction parallel to the longitudinal axis 16 towards the first end 18 of the wall portion 14. The divider wall 10 further includes a rear leg 28 extending from the wall portion 14 adjacent the second end 20, the rear leg 28 extending normal to the longitudinal axis 16 of the wall portion 14.

[0049]As illustrated in FIGS. 5 and 7A to 7D, the first front leg 22 is adapted to be received int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com