Wound filling apparatuses and methods

a filling apparatus and wound technology, applied in the field of wound filling apparatuses and methods, can solve the problems of affecting the healing effect of wounds, the actual form of gauze as it is packed into wounds is very variable, and patients, so as to achieve the effect of reducing the damage and trauma of wounds, facilitating healing, and facilitating healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

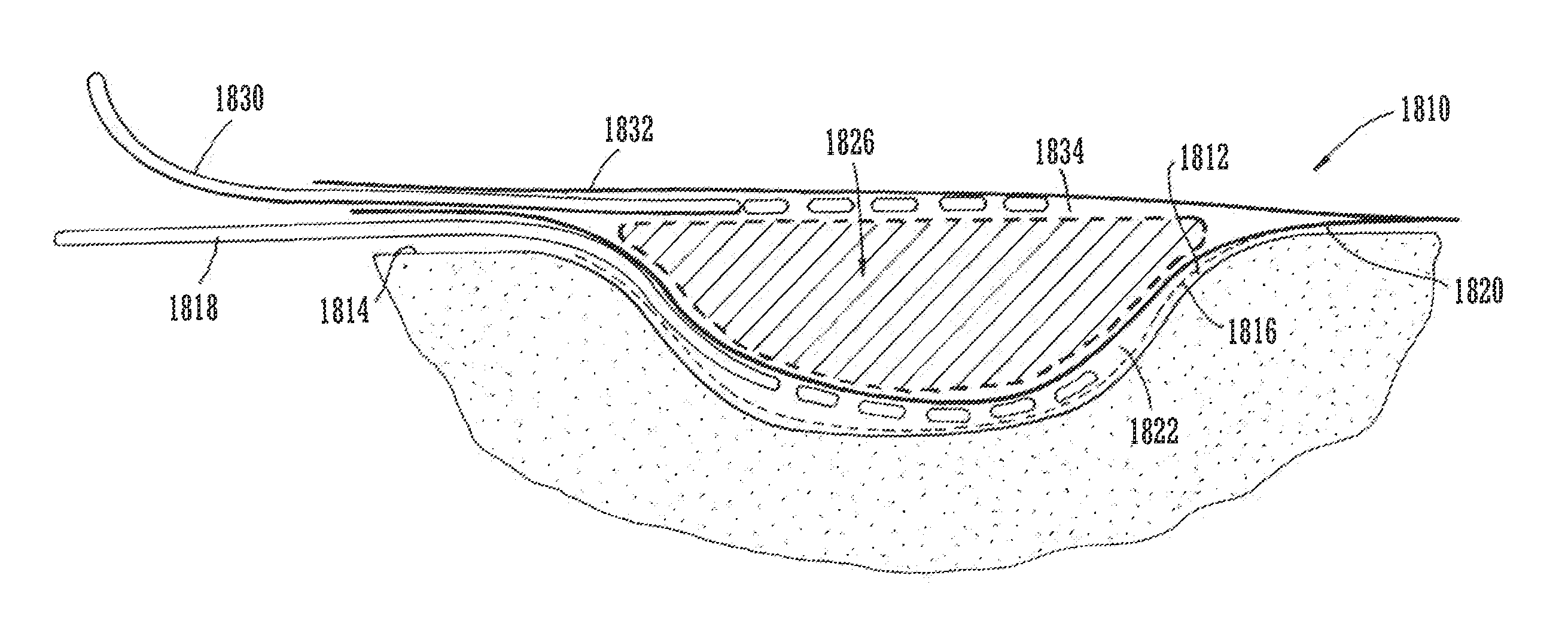

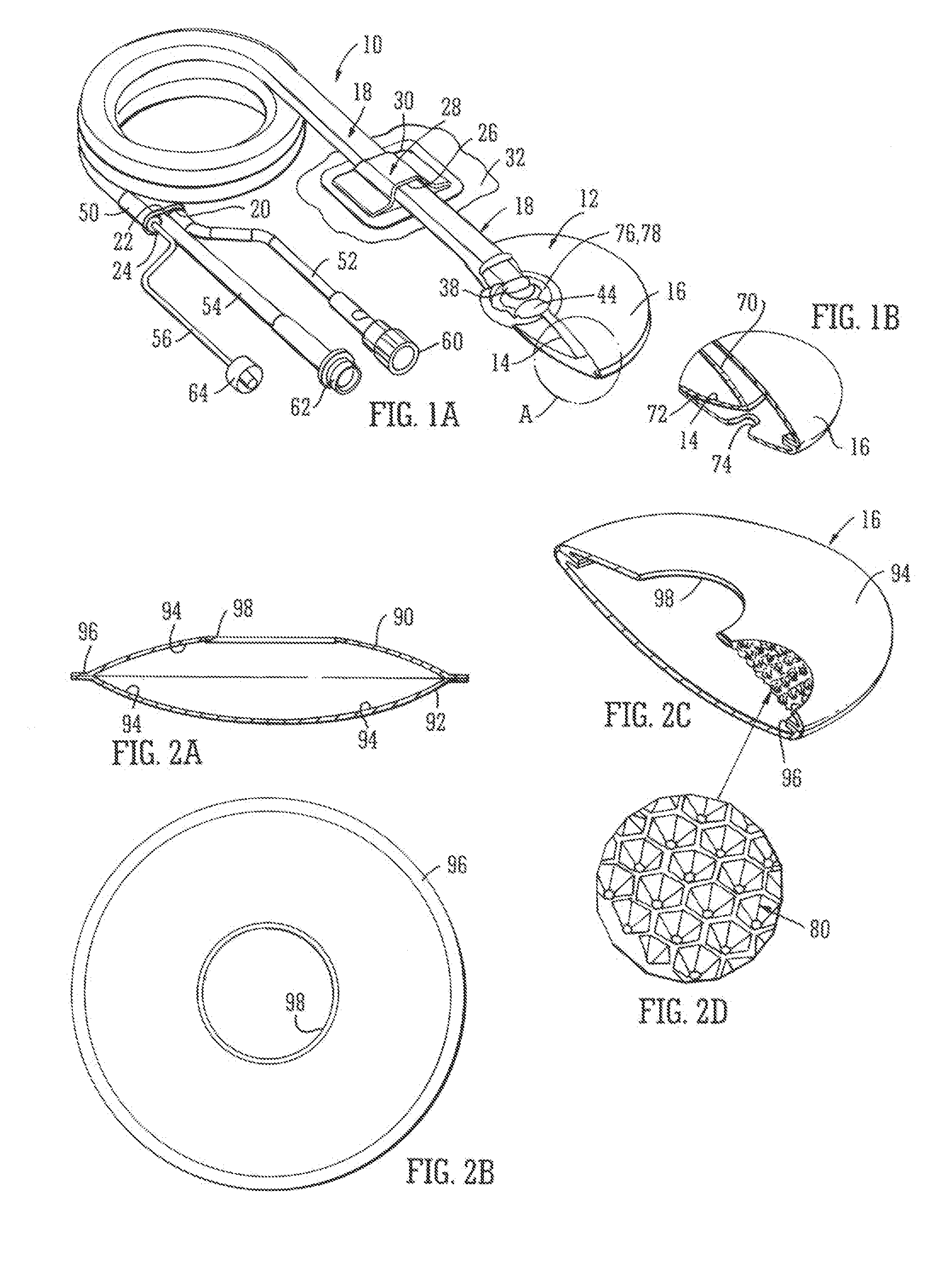

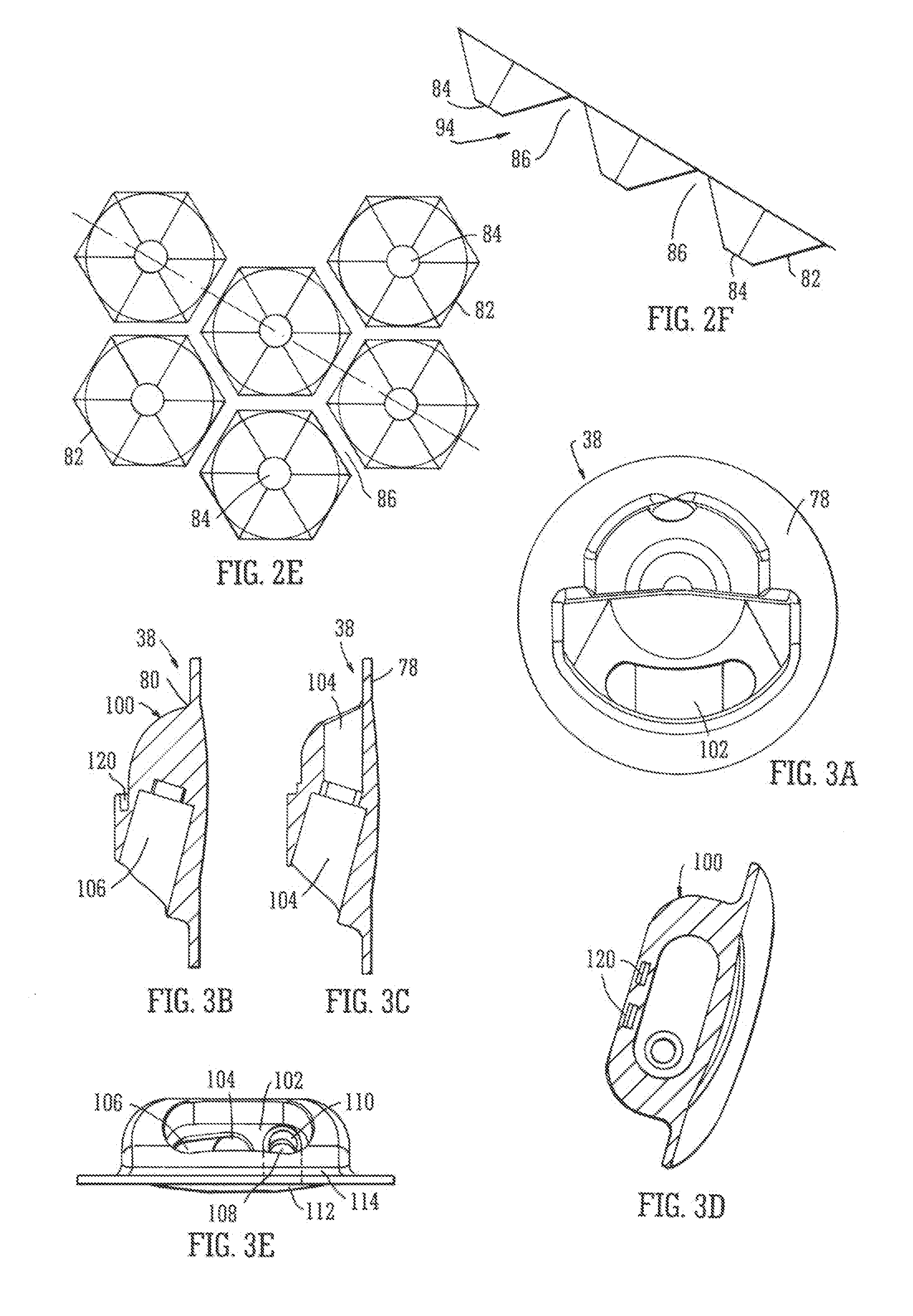

[0149]Referring now to the drawings and where the same features are denoted by common reference numerals, FIGS. 1A and 1B show a perspective view of one embodiment of a device 10 and FIG. 5 shows a schematic cross section of the device installed in a wound cavity. The device comprises a wound filling inflatable device 12 which may comprise an inflatable bag member 14 and a sock member 16. The inflatable wound filling device 12 is shown in FIG. 1 part sectioned and a detail “A” is shown at a greater magnification in FIG. 1B. The device also comprises a multi-lumen conduit 18 (shown coiled up prior to use) having three separate lumens 20, 22, 24 therethrough. The conduit 18 passes through a hole 26 in a grommet member 28 which itself is adhered by a flange 30 around the periphery of the grommet member 28 to a dressing 32 which is shown in part only and which adheres the grommet 28 to a patients' skin 34 (FIG. 5) adjacent a wound 36 to which TNP therapy is to be applied. The arrangemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com