Confectionery product containing active and/or reactive components and methods of production thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

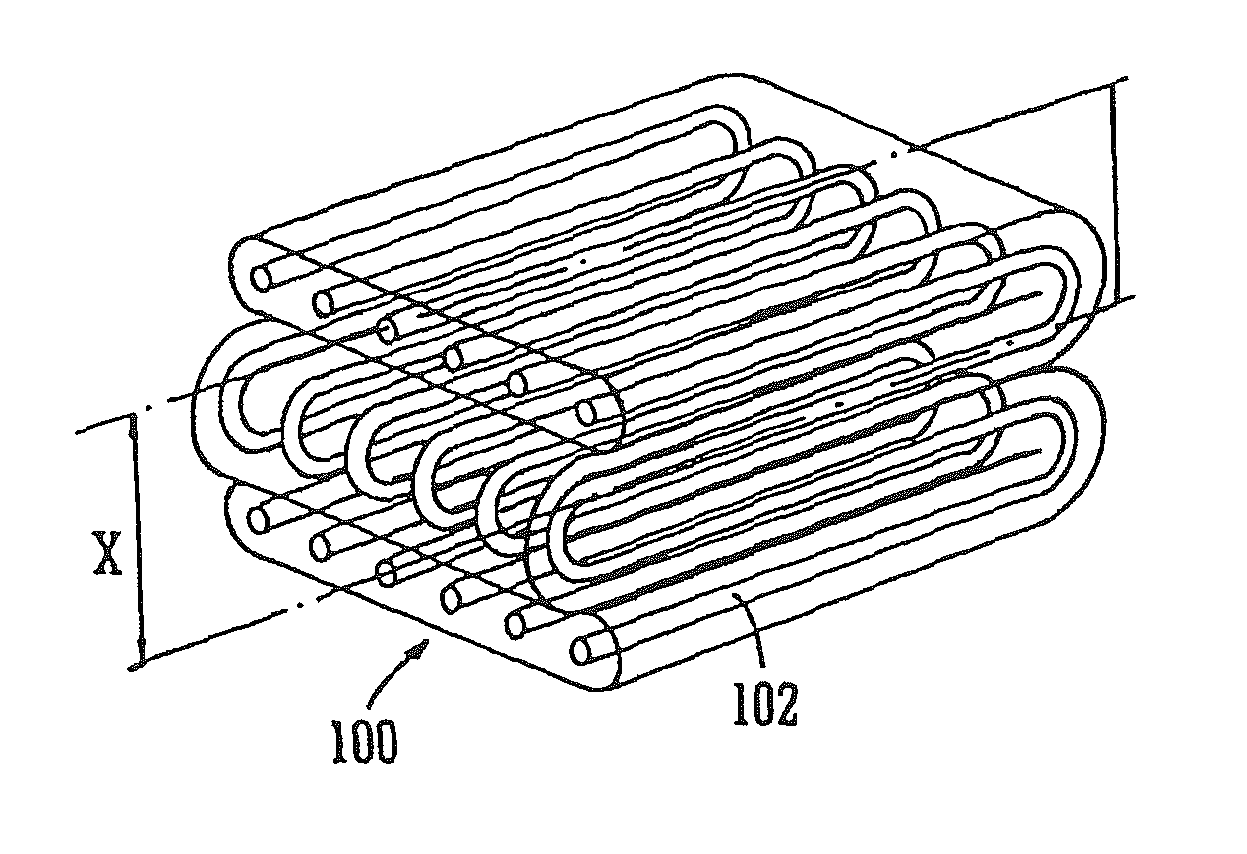

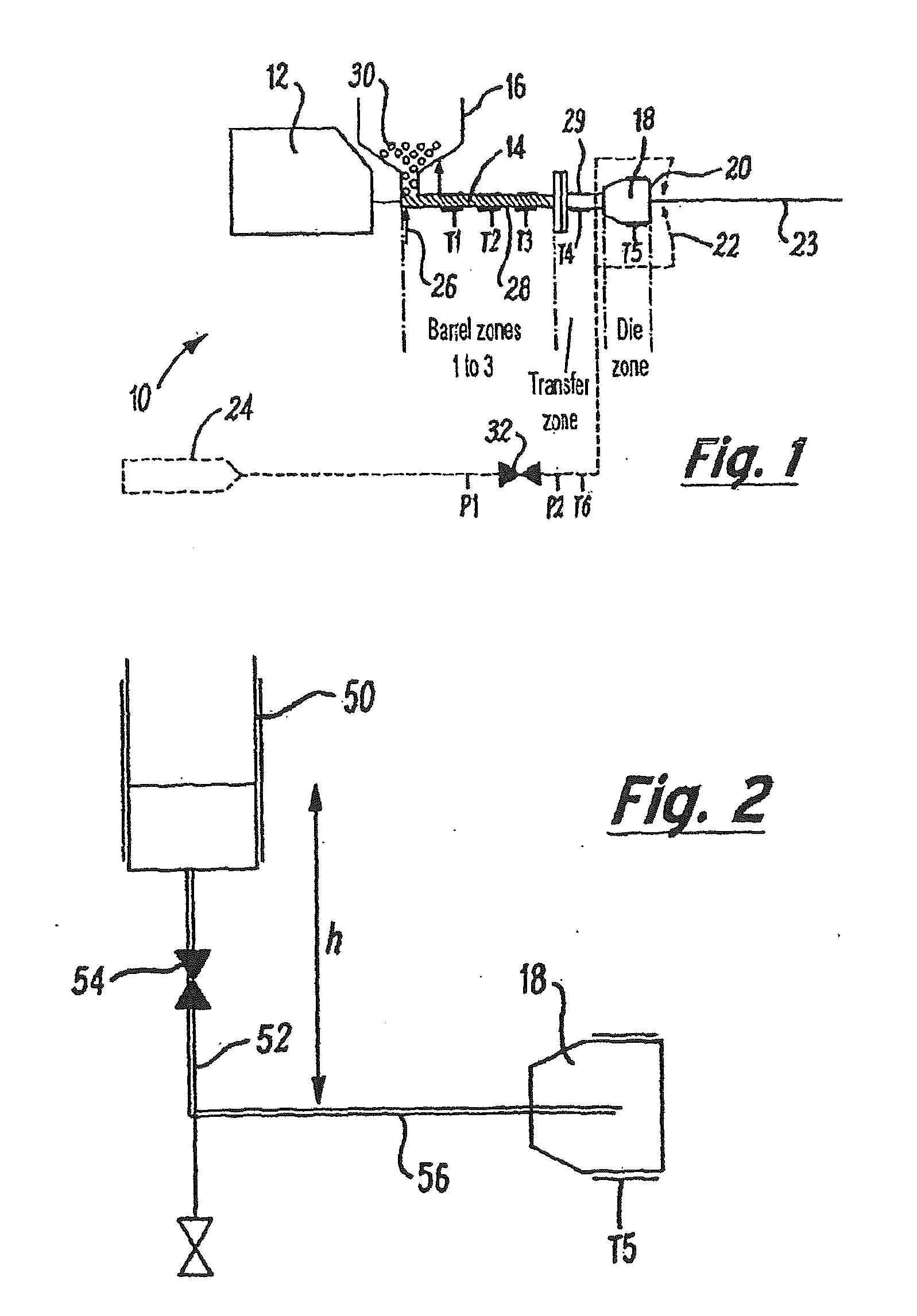

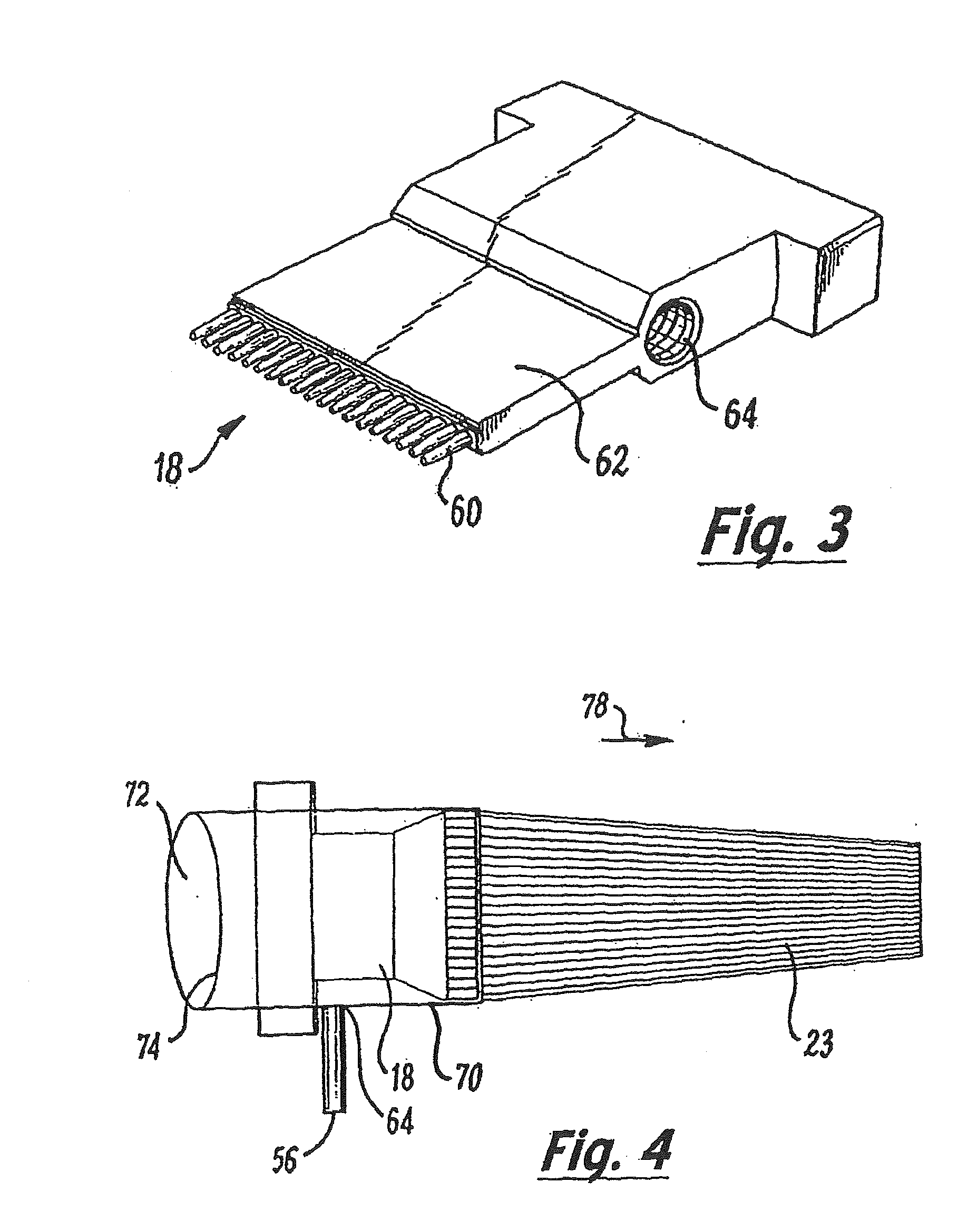

[0226]Phase one concerned the extrusion of candy using a capillary die attached to a small-scale extruder, in order to confirm that candy having capillaries with both low and high voidage values could be formed in accordance with the present invention.

[0227]The materials that were trialled during this investigation are shown in Table 1.

TABLE 1Materials tested.MaterialnumberMaterial nameMajority ingredientsApplication1CustomSugar (40%) GlucoseExtruded matrixrecipe 1Syrup (60%)2CustomMaltitol syrup (96%) GumExtruded matrixrecipe 2Arabic (2%) Water (2%)3Cocoa butterCocoa butter (100%)Capillary filler

[0228]Materials 1 and 2 were supplied as large solid blocks. All materials were crushed prior to extrusion to yield a fine granular powder, with grain sizes ranging between 1 mm and 5 mm. Material 3 was supplied as a tub of solidified cocoa butter; the required quantity was broken up into a fine powder containing only small lumps before being fed into the heated cocoa butter reservoir.

[0229...

example 2

[0251]The third phase built upon the first two phases described in Example 1 and recreated the working environment with food grade equipment in a food grade environment. This food-grade setup extruded hard candy, chocolate and chewing gum with air, liquid and solid centres. This range of filled extrudates were made in a food grade environment and were consumed to investigate their edible properties.

[0252]The following edible materials were used in these experiments:

[0253]Chewing gum (uncoated Peppermint-Spearmint Higher flavour chewing gum pellets); hard candy, mint candy (Extra Strong Mints®, Jakemans® Old Favourites), fruit candy (Summer Fruits, Jakemans® Old Favourites), chocolate (milk chocolate (with 0, ½, 1, 2% added water), Cadbury® Dairy Milk® Buttons—when used molten, 2% PGPR was added to lower the melt viscosity for ease of use (c.f. legal limit of ½%)), compound chocolate (Plain Belgian Chocolate, SuperCook®), 72% Cook's Chocolate, Green & Black's®. Liquid fillings used i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com