Aluminum electrolytic cell having cathode carbon block with columnar protrusions embedded on its upper surface

a technology cathode carbon block, which is applied in the direction of electrolytic process, electrolytic capacitor, electrolytic components, etc., can solve the problems of high material consumption, poor strength and erosion resistance of cathode carbon block to aluminum liquid in the electrolytic cell, and inability to meet the requirements of aluminum electrolytic, etc., to improve the working ability of cathode carbon block, reduce the effect of filtrate fluctuation ability and increasing the life of the cathode carbon block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

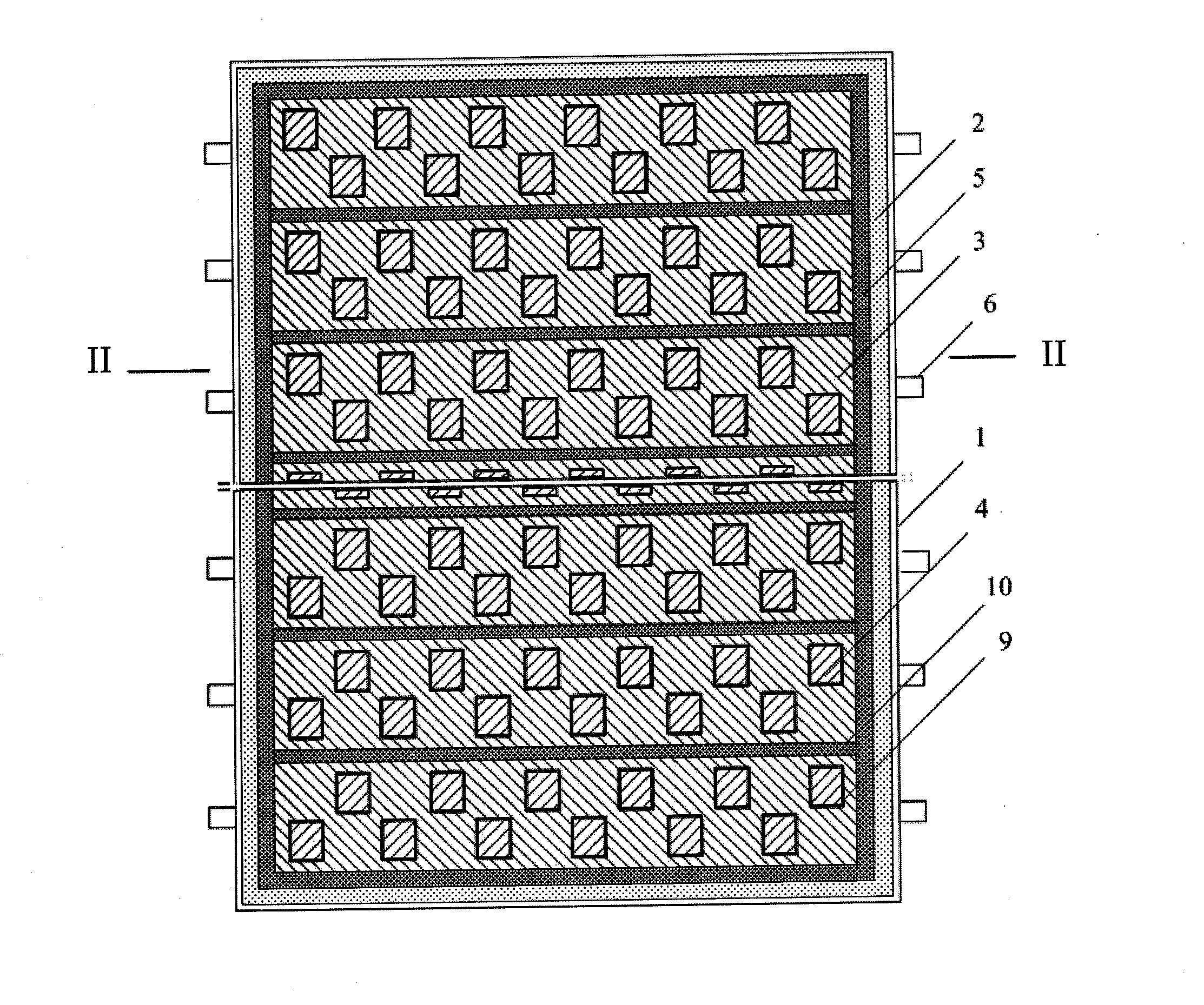

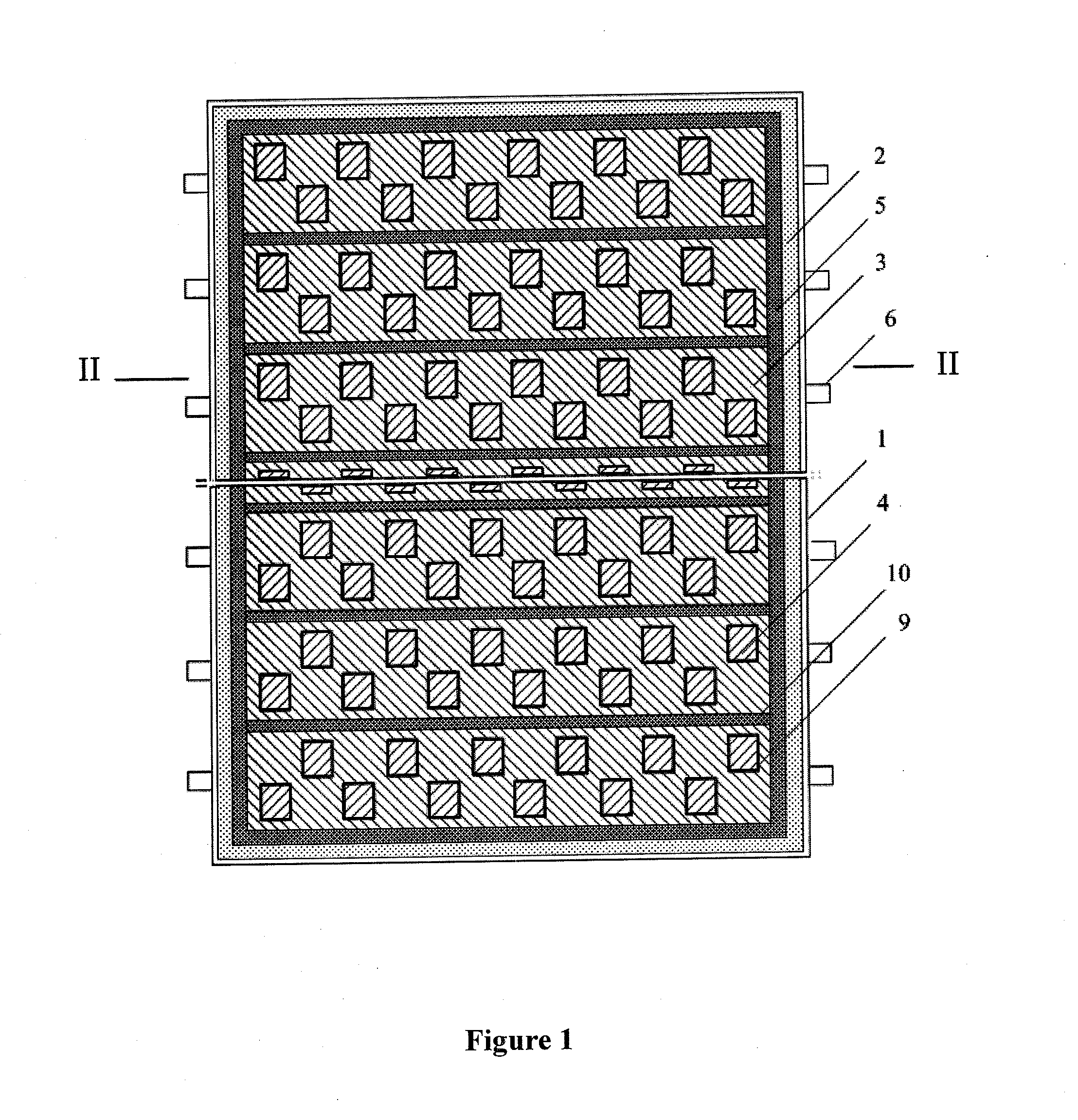

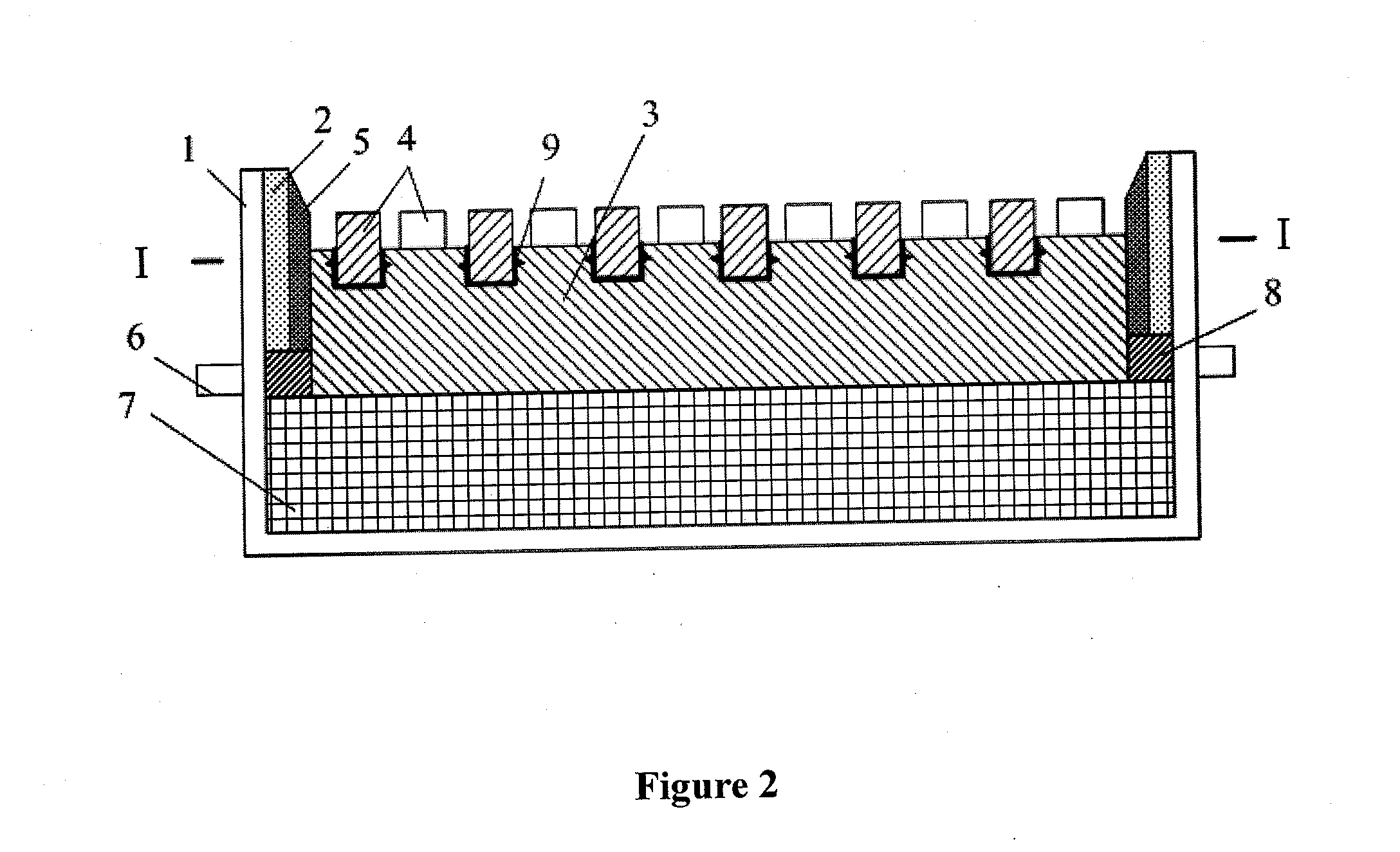

[0044]The aluminum electrolytic cell having cathode carbon block with columnar protrusions embedded on its upper surface is shown in FIG. 1, and the sectional view taken along line II-II in FIG. 1 is shown in FIG. 2. The electrolytic cell comprises a cell shell 1, a cell lining refractory insulation material, side carbon bricks 2, cathode carbon blocks and cathode steel bars 6. Carbon ramming paste between cathode carbon blocks 10 is filled between two cathode carbon blocks, and each cathode carbon block is rammed with each side carbon brick by the carbon paste 5; wherein the cathode carbon block consists of a cathode carbon block substrate 3 and columnar protrusions 4 on the upper surface of the cathode carbon block substrate 3, and the columnar protrusions 4 are embedded on the upper surface of the cathode carbon block substrate 1. The cell lining refractory insulation material comprises a cell bottom refractory insulation material 7 and a cell side refractory insulation material ...

example 2

[0050]The aluminum electrolytic cell having cathode carbon block with columnar protrusions embedded on its upper surface is shown in FIG. 3, and the sectional view taken along line IV-IV in FIG. 3 is shown in FIG. 4. The structure of the electrolytic cell is consistent with that of the electrolytic cell in example 1, and is differentia from that of the electrolytic cell in example 1 in that:

[0051]The columnar protrusions are arranged in three rows in the length direction of the upper surface of the cathode carbon block substrate, the length of the columnar protrusions is 21 cm, the width of the columnar protrusions is 19 cm, and the height difference between the columnar protrusions and the upper surface of the cathode carbon block substrate is 10 cm. The distance between two adjacent columnar protrusions of the columnar protrusions of the same row is 25 cm, the distance between two adjacent columnar protrusions of the columnar protrusions of different rows on the same cathode carbo...

example 3

[0054]The aluminum electrolytic cell having cathode carbon block with columnar protrusions embedded on its upper surface is shown in FIG. 5, and the sectional view taken along line VI-VI in FIG. 5 is shown in FIG. 6. The structure of the electrolytic cell is consistent with that of the electrolytic cell in example 1, and is differentia from that of the electrolytic cell in example 1 in that:

[0055]Under the condition that the columnar protrusions are cylindrical and the width of the cathode carbon block substrate is 50-70 cm, the diameter of the columnar protrusions is 25 cm, the height difference between the columnar protrusions and the upper surface of the cathode carbon block substrate is 11 cm, the distance between two adjacent columnar protrusions of the columnar protrusions of the same row is 30 cm, the distance between two adjacent columnar protrusions of the columnar protrusions of different rows on the same cathode carbon block is 20 cm, and the distance between two columnar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com