Cellulose Based Recyclable Container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

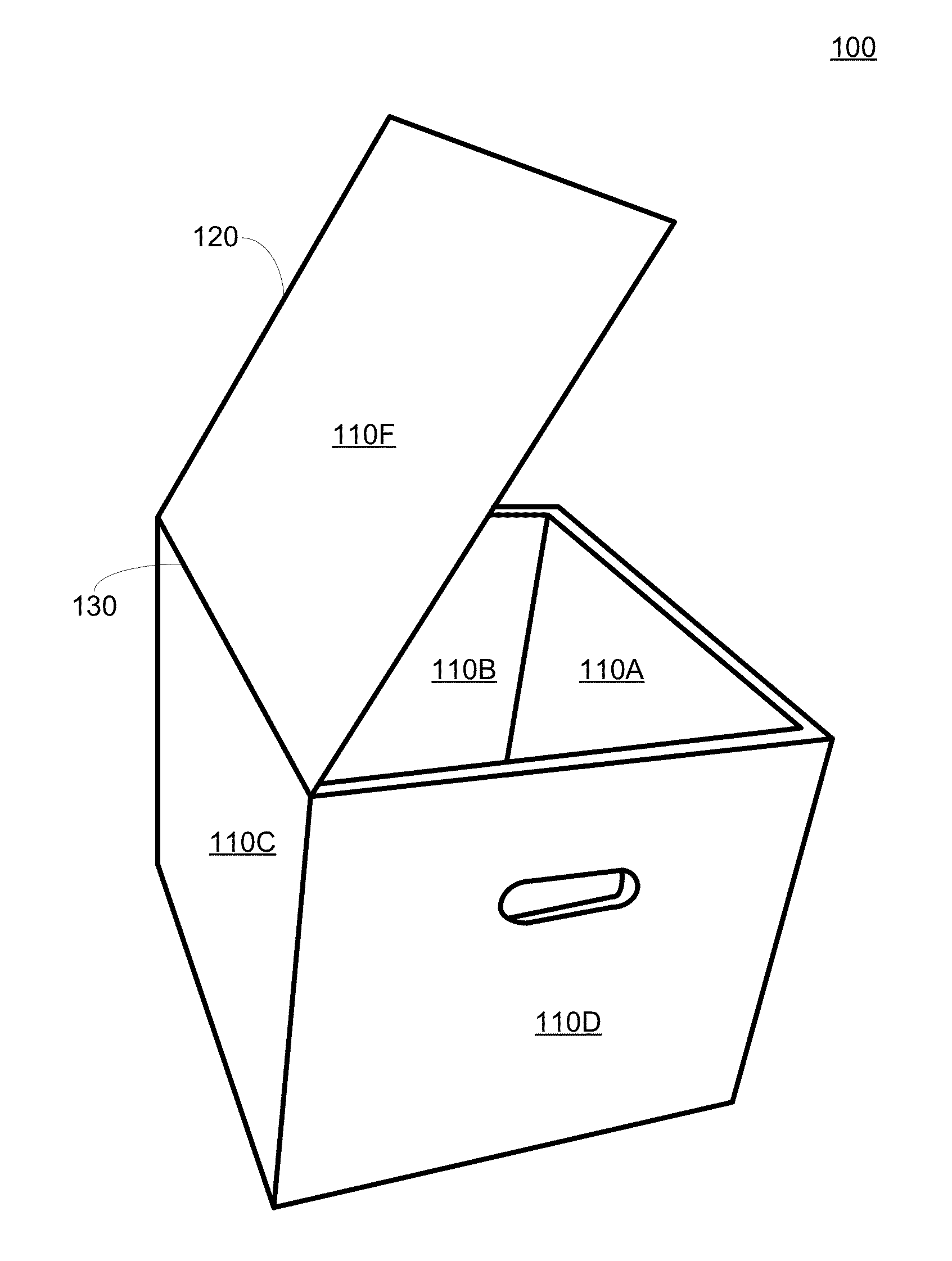

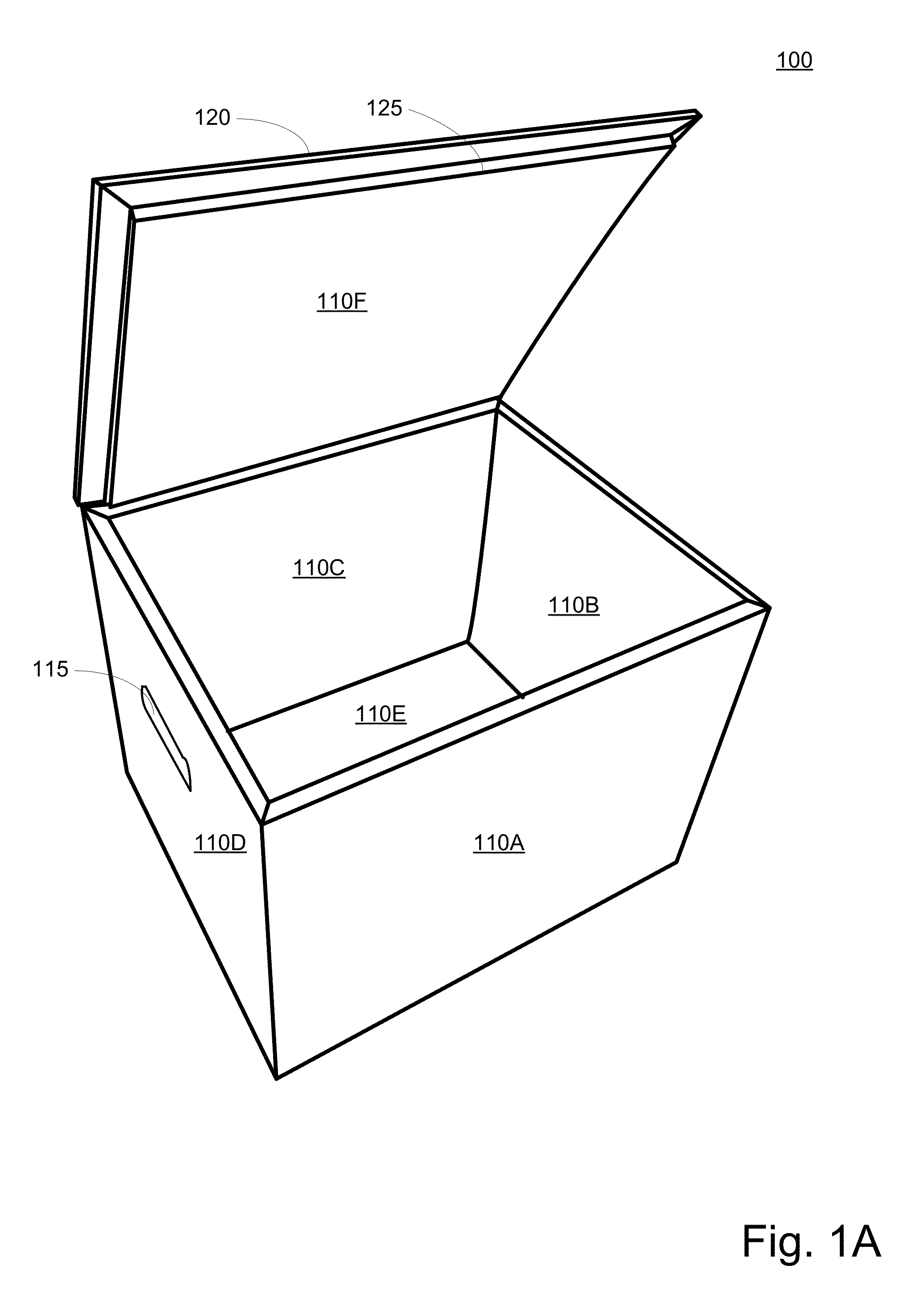

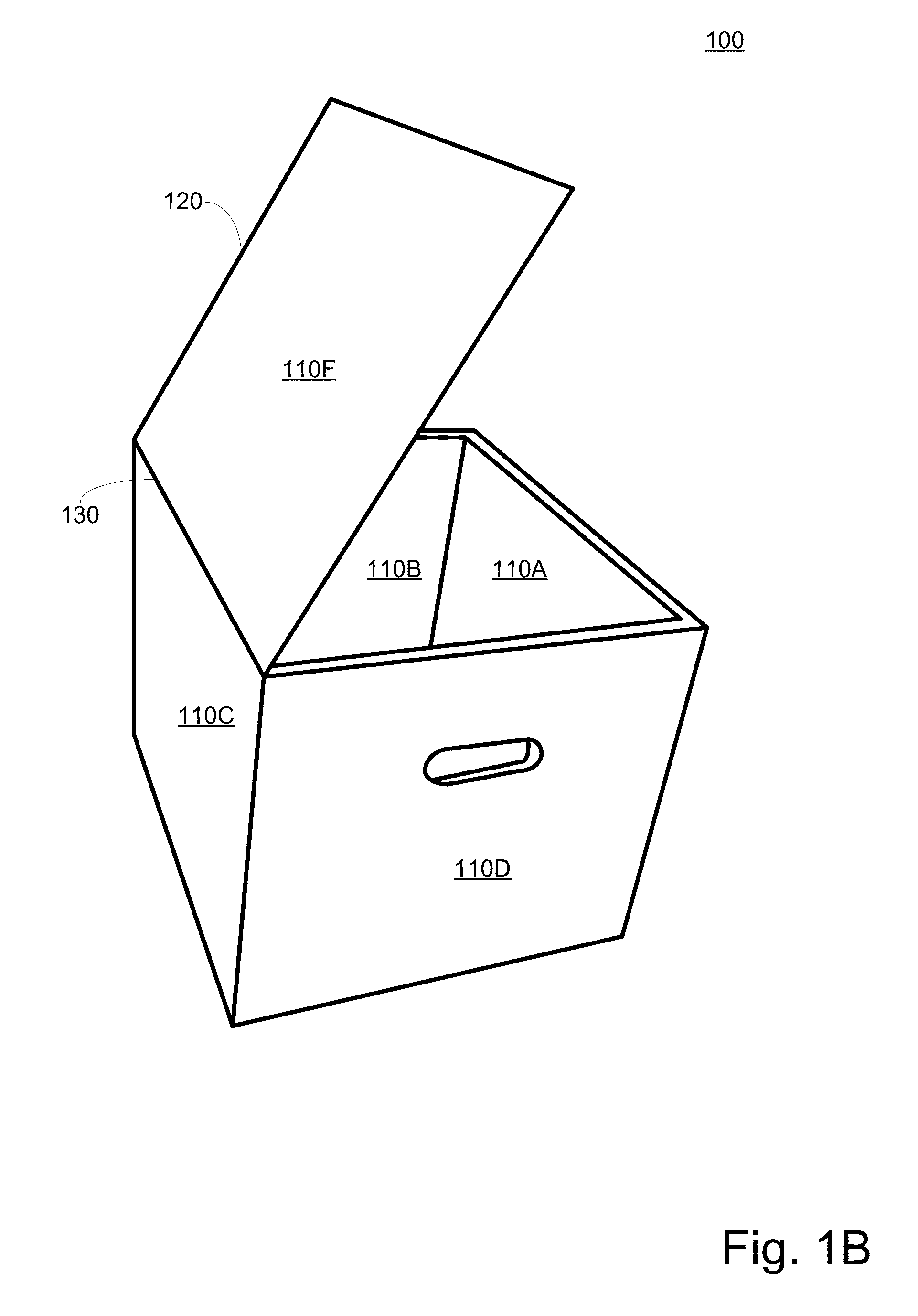

exemplary embodiment 100

[0062]FIGS. 9A-9B depict the exemplary embodiment 100, shown closed in FIG. 9A and open in FIG. 9B. As can be seen in FIG. 9B, the portable container 100 may contain items 905. Advantageously, the temperature of the items 905 may be maintained or regulated by virtue of the restricted heat transfer attributable to the portable container 100. It is envisioned that certain embodiments of a portable cellulose container 100, may be prepackaged for retail to include items 905, such as canned beverages. As one of ordinary skill in the art would recognized, a prepackaged embodiment of a portable cellulose container 100 may be bought by a consumer, opened and filled with ice around the items 905.

[0063]FIGS. 10A-10B depict exploded views of the exemplary embodiment 100. In the FIG. 10 illustrations, he various insulating boards 201 can be seen positioned relative to corresponding walls 705 of the inner shell. Also, the position of the extensions 720 and tabs 715 of the inner shell component c...

exemplary embodiment 1300

[0066]FIGS. 13A-13B depict an exemplary embodiment 1300 of a cellulose based portable container configured to contain a wine bottle or other item of similar size. Advantageously, a cellulose based portable container such as the exemplary embodiment 1300 will be suitable for maintaining or regulating the temperature of an item contained within it. Because the inner and outer shell components and insulating components may retard the transfer of thermal energy, the temperature of an item within the container may be controlled.

exemplary embodiment 1400

[0067]FIG. 14 depicts an exemplary embodiment 1400 of a cellulose based portable container configured with an insulated chamber 1405 and a non-insulated chamber 1410. Advantageously, for items in need of temperature regulation such as, for example, a chilled bottle of white wine, the insulated chamber 1405 may substantially retard thermal energy transfer to such an extent that the temperature of the item may be controlled. By contrast, for items that do not require much if any temperature regulation such as, for example, a room temperature bottle of red wine, the non-insulated chamber 1410 may serve as a convenient means for containing, protecting and transporting the item.

[0068]FIG. 15 depicts exemplary embodiments 1500 of a cellulose based portable container with octagonal outer shell components.

[0069]FIG. 16 illustrates an exemplary outer shell pattern that may be folded along the various creases to form an outer shell component of an exemplary portable container according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com