Exhaust heating apparatus for internal combustion engine and control method for the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

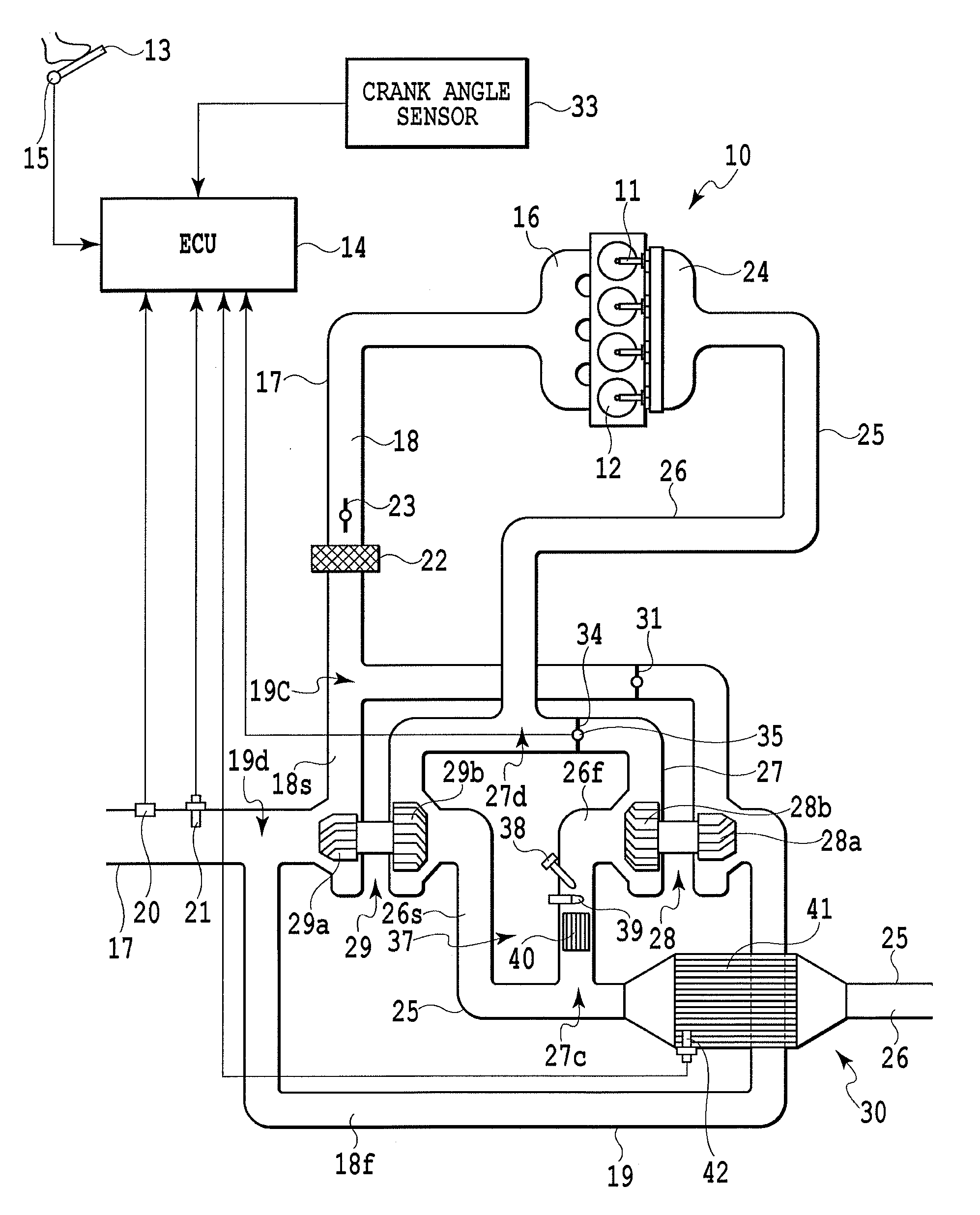

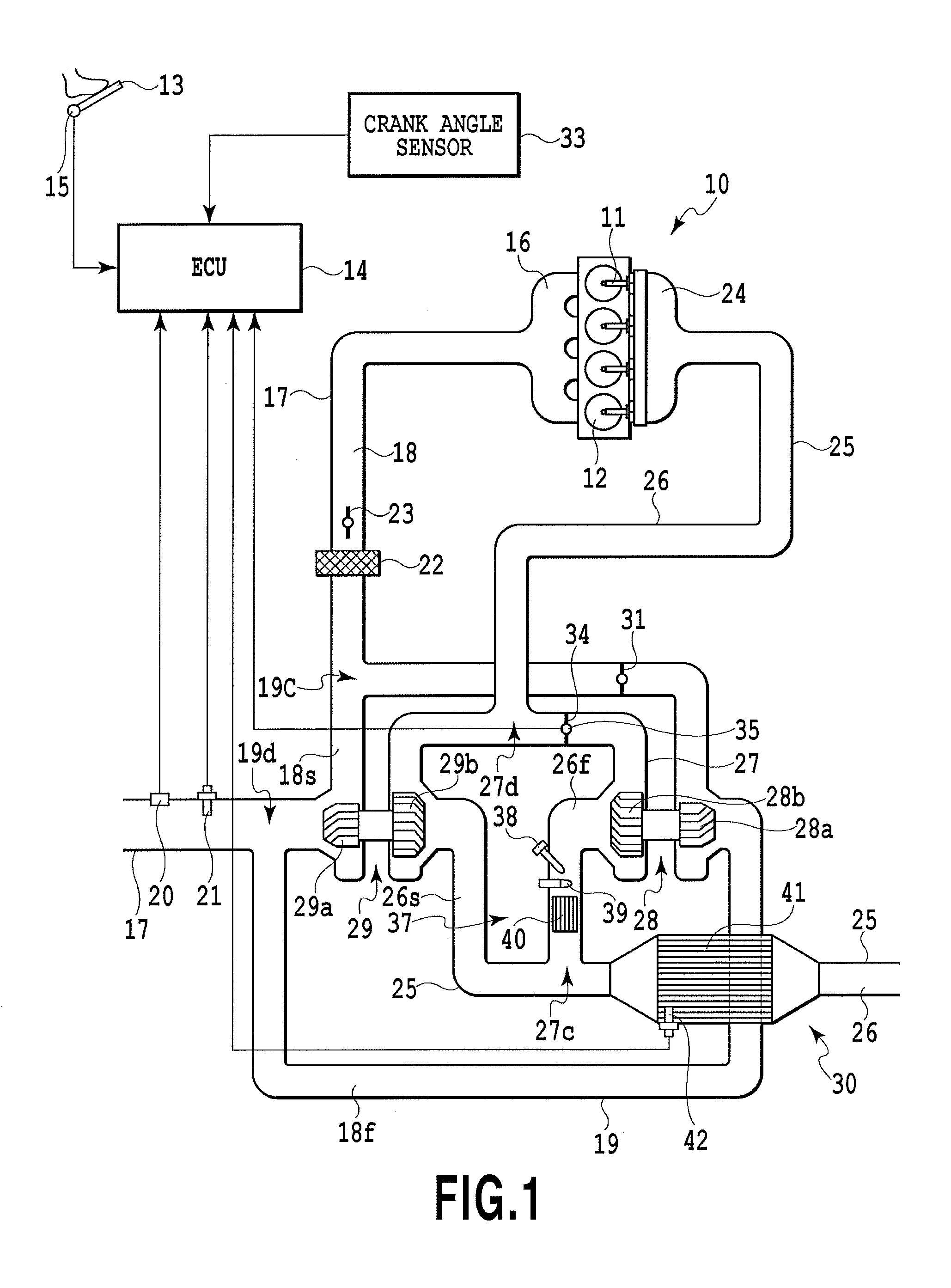

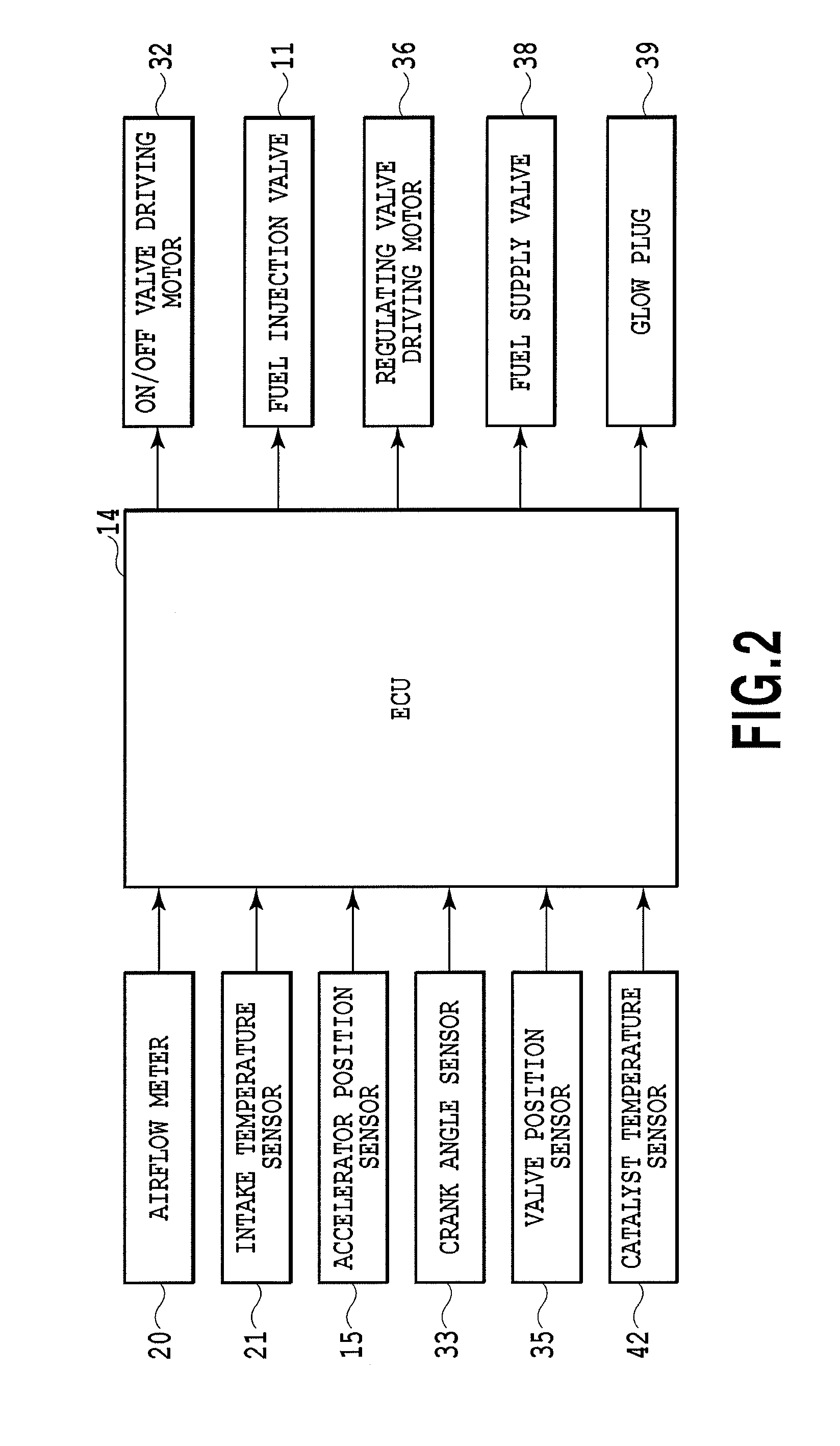

[0028]An embodiment in which the present invention is applied to a compression ignition type internal combustion engine in which parallel-type 2-stage exhaust turbochargers are incorporated will be explained in detail with reference to FIGS. 1 to 4. The present invention is not, however, limited to the embodiment, and the construction thereof may be freely modified corresponding to required characteristics. The present invention is effectively applied to a spark ignition type internal combustion engine in which gasoline, alcohol, LNG (Liquefied Natural Gas) or the like is used as fuel to be ignited by a spark plug, for example.

[0029]Main components of an engine system of the embodiment are illustrated schematically in FIG. 1, and a control block thereof is illustrated in FIG. 2, however, a valve mechanism for intake and exhaust, an EGR system, and the like are omitted for convenience. The engine 10 according to the present embodiment is a compression-ignition multicylinder (four cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com