Fiber composite component assembly having at least two plate-shaped composite structures and processes for preparing same

a composite component and plate-shaped technology, applied in the field of fiber composite component assemblies, can solve the problems of increasing production expenditure and requiring additional reinforcement of connections, and achieve the effect of high load and damage toleran

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

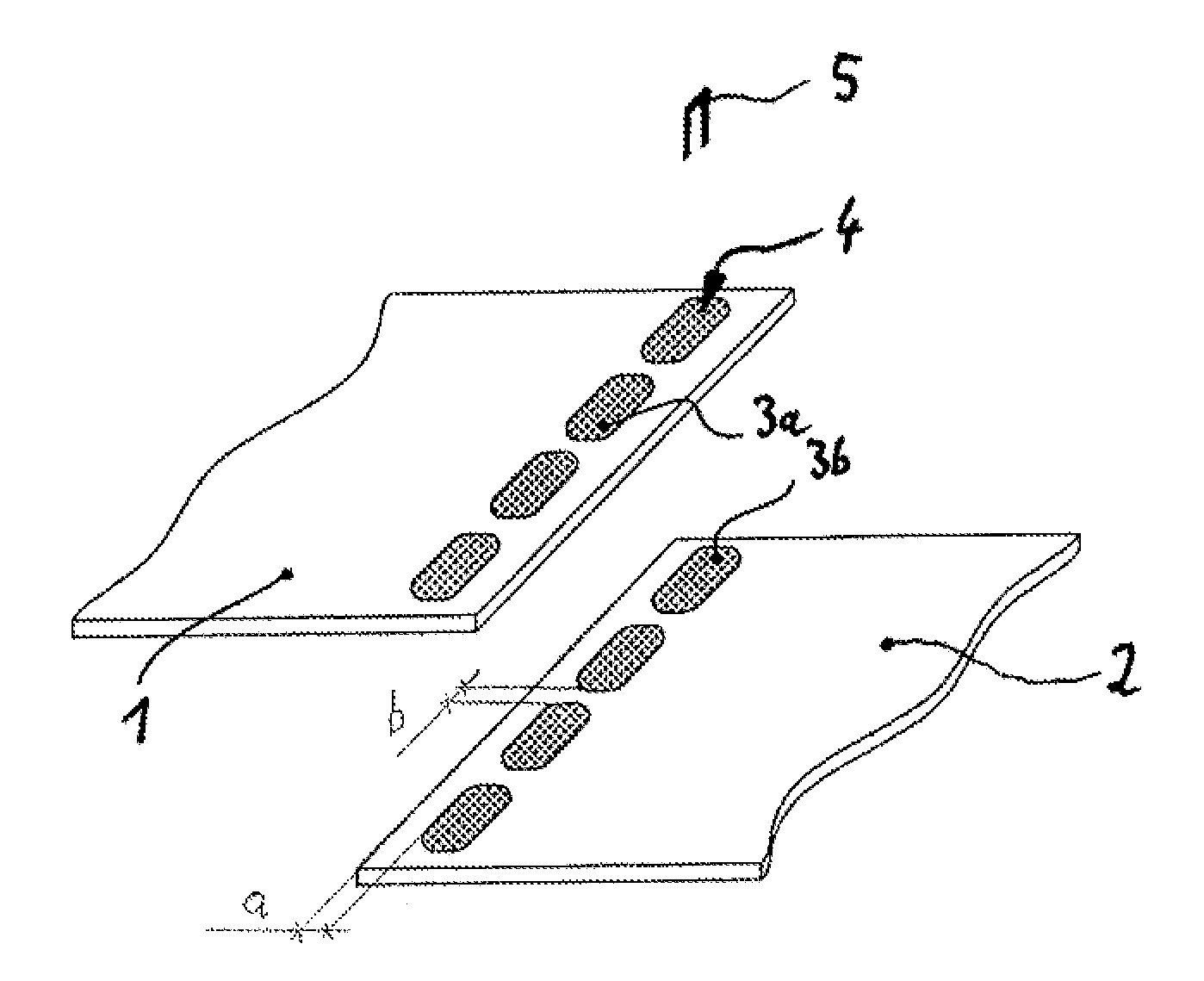

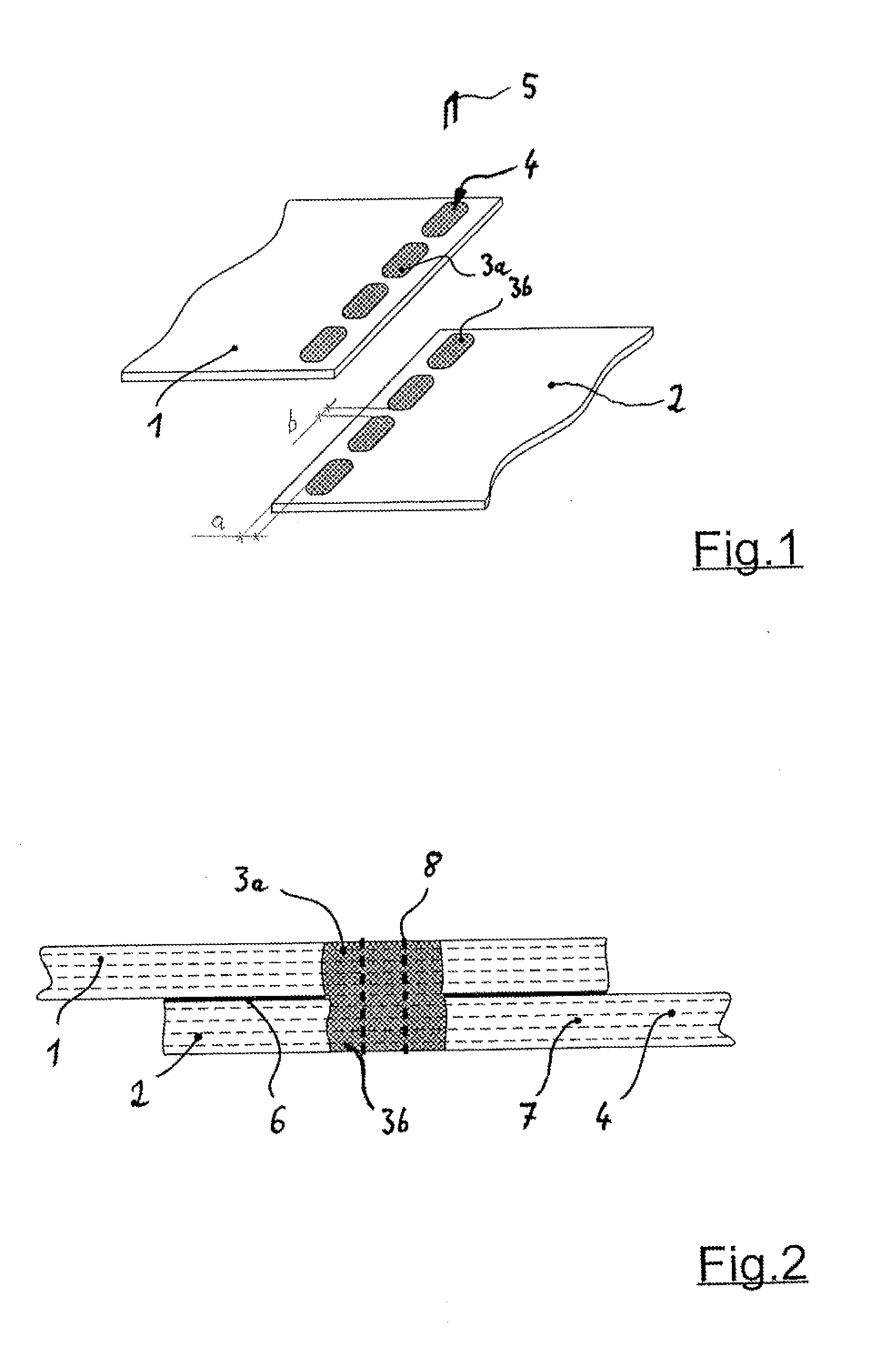

[0024]According to FIG. 1 two plate-shaped composite components 1 and 2 of an aircraft structure (not shown in detail) in the edge region comprise several partial regions 3a or 3b which can be brought to flush conformity with each other and which are arranged so as to be spaced apart from each other. While the fiber composite components 1 and 2 outside these partial regions 3a and 3b are cured, only fibers 4 without a plastic matrix extend through the partial regions 3a and 3b.

[0025]This forms a prerequisite for the two plate-shaped fiber composite components 1 and 2 to be interconnected during installation, by way of additional mechanical reinforcement means in the form of pins 5, in addition to bonding. In this embodiment each partial region 3a, 3b that does not contain synthetic resin is completely enclosed by a cured region of the fiber composite component 1 or 2, thus in each case forming an essentially rectangular region. The partial regions 3a and 3b that do not contain synt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

| mechanical reinforcement | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com