Thermal receptacle with phase change material

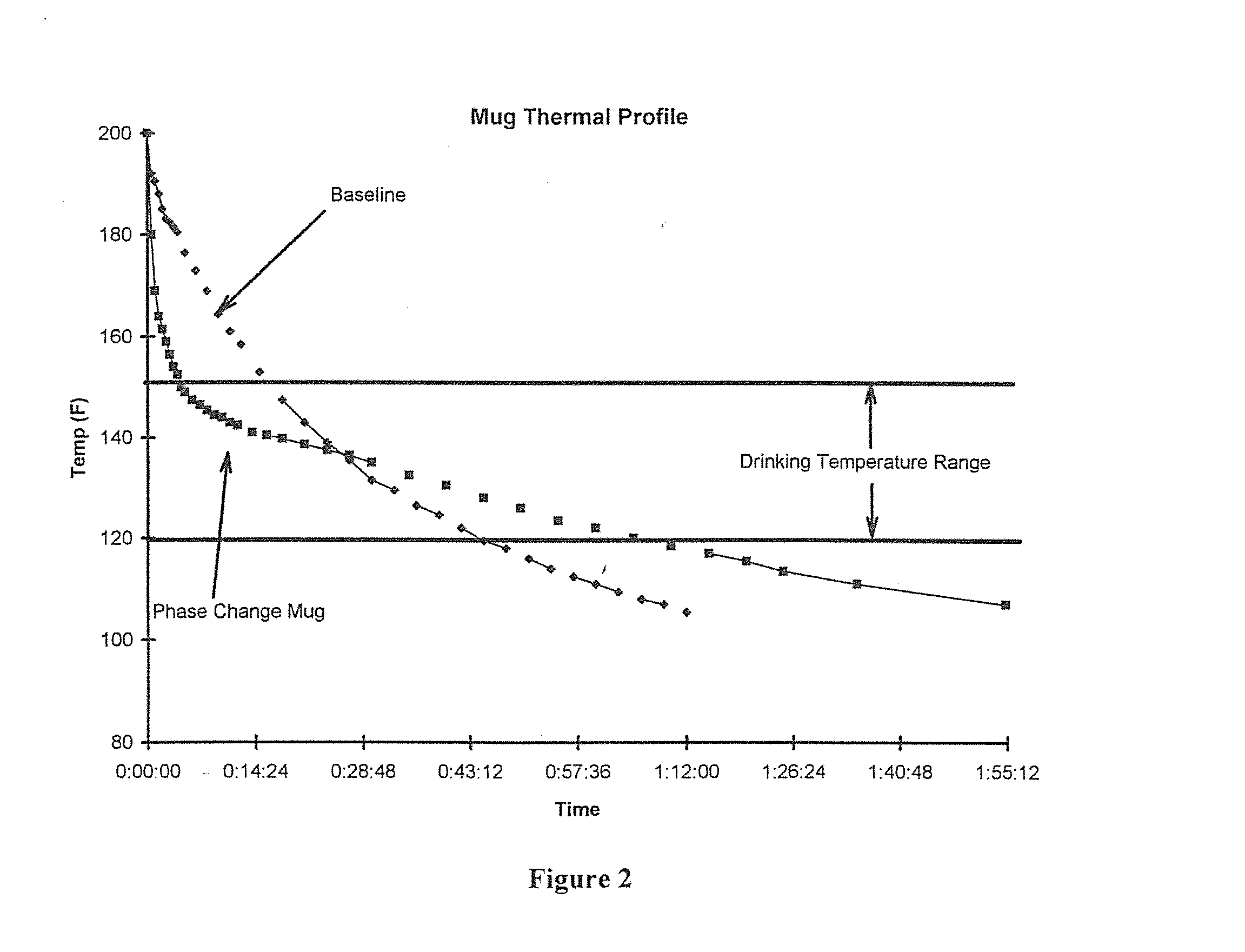

a technology of phase change material and thermal receptacle, which is applied in the direction of indirect heat exchanger, lighting and heating apparatus, domestic cooling apparatus, etc., can solve the problems of reducing the temperature of hot beverages, burning to the mouth, and skin burns,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

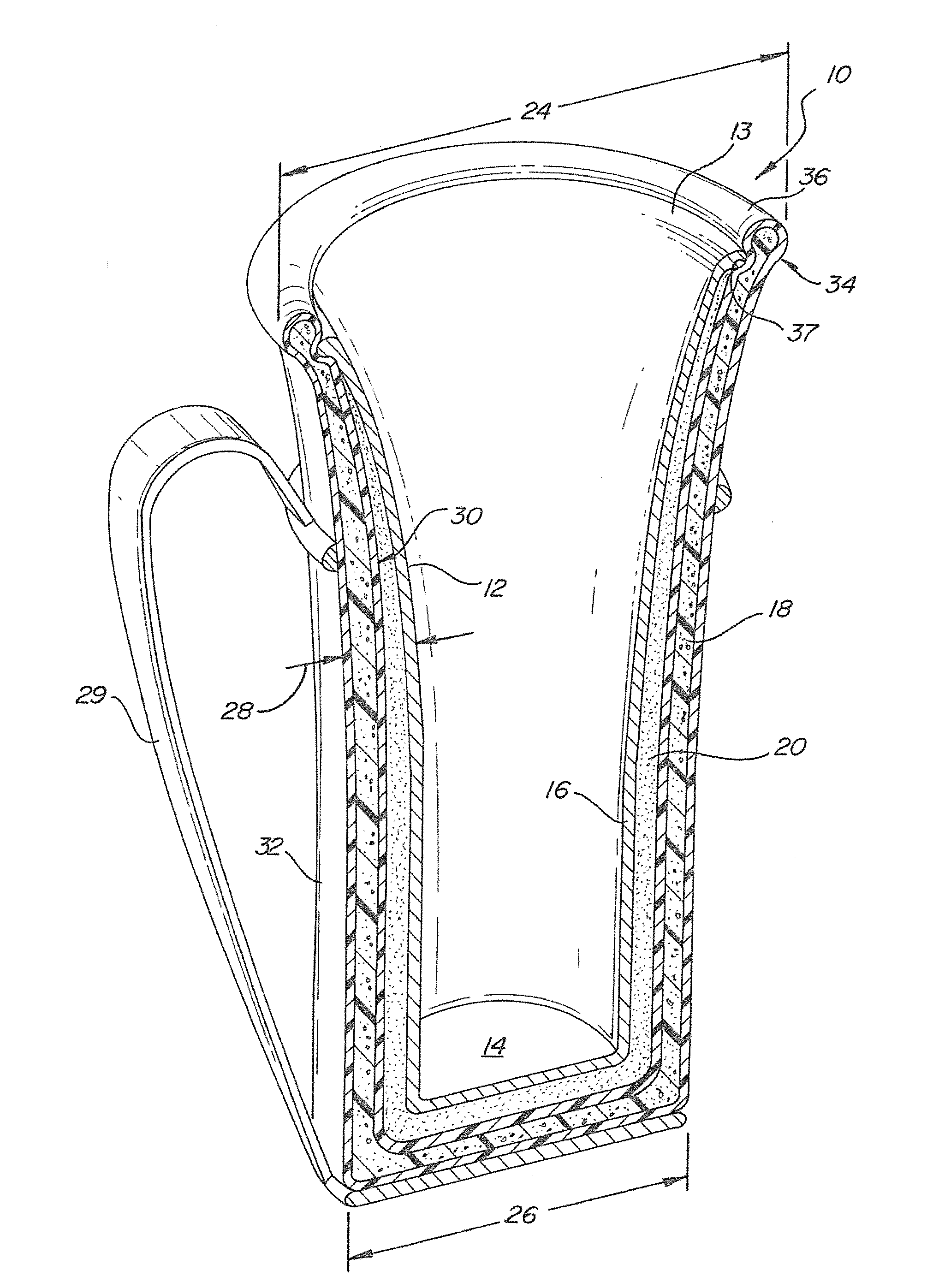

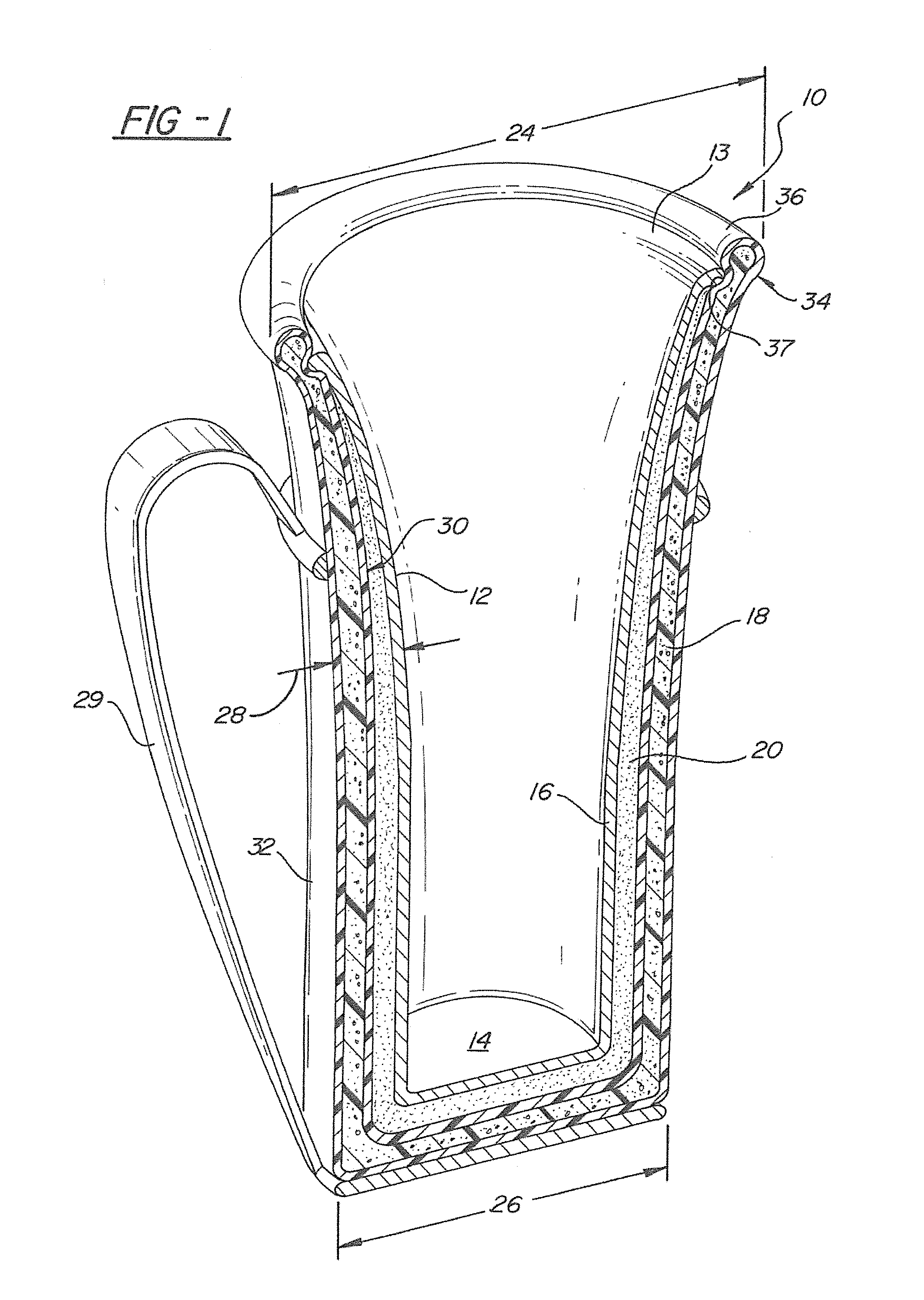

[0049]Referring to the Figures, wherein like numerals indicate like or corresponding parts throughout the several views, a liquid receptacle is generally indicated at 10. The receptacle 10 includes a inner vessel 12 with an open upper end 13 and a closed lower end 14 and a wall 16 connecting the upper 13 and lower 14 ends. An insulated outer shell 18 is spaced from the inner vessel 12 defining an interstitial chamber 20 therebetween. Phase change material is disposed within the chamber 20.

[0050]Preferably, the inner vessel 12 is either wholly or partially formed of a material having a high thermal conductivity such as aluminum, copper or alloys thereof. Pure aluminum has a thermal conductivity of 237 Watts / meter-degree Kelvin when measured at 300 degrees Kelvin. Most aluminum alloys have a thermal conductivity above 150 Watts / meter-degree Kelvin. Pure copper has a thermal conductivity of 401 Watts / meter-degree Kelvin. Most alloys of copper have thermal conductivities significantly l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com