Laser Sight Firing Device Mountable To An Air Gun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]Before the present invention is described in greater detail in connection with the preferred embodiments, it should be noted that similar elements and structures are designated by like reference numerals throughout the entire disclosure.

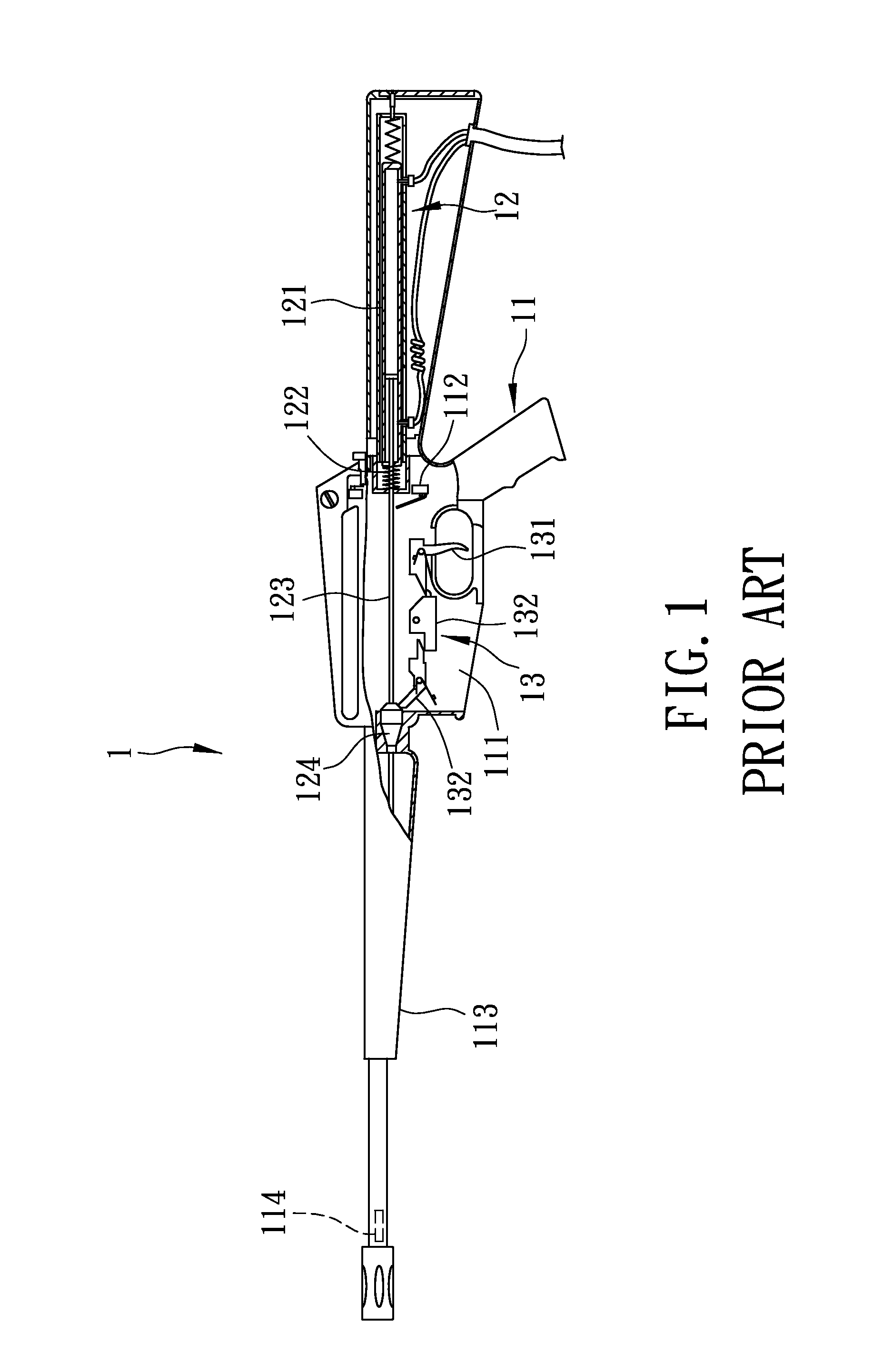

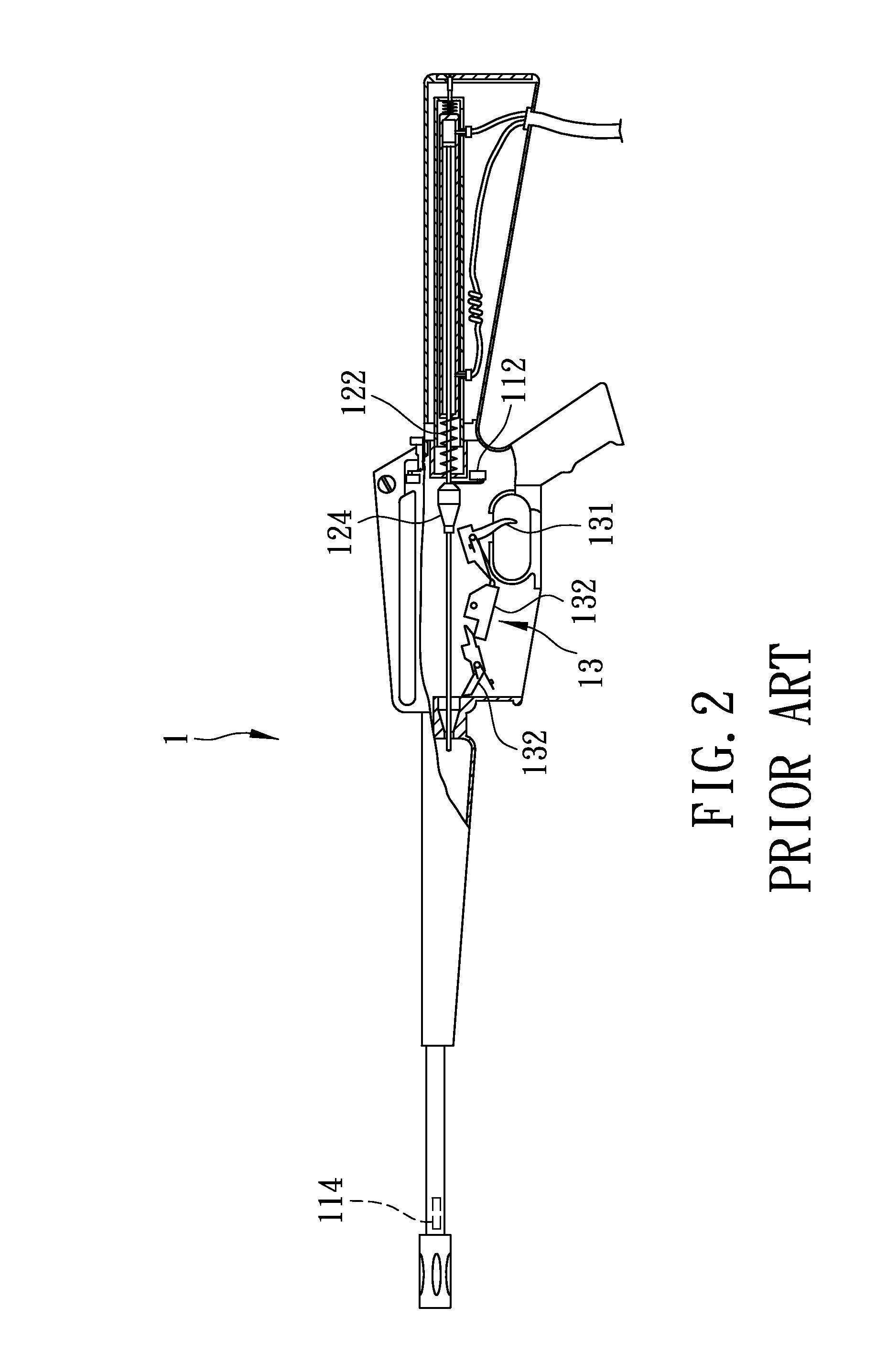

[0033]Referring to FIGS. 3 and 4, the first preferred embodiment of a laser sight firing device 2 according to this invention is disposed on an air gun 3 for simulating a real shooting. In this embodiment, the air gun 3 is configured as a rifle. The air gun 3 includes a main body 31, a gun barrel 32 connected to the main body 31, and a trigger 33 connected to the main body 31 and operable for driving emission of a high-pressure air current from the main body 31 and through the gun barrel 32. The gun barrel 32 is formed with a muzzle 321 at an end thereof distal from the main body 31.

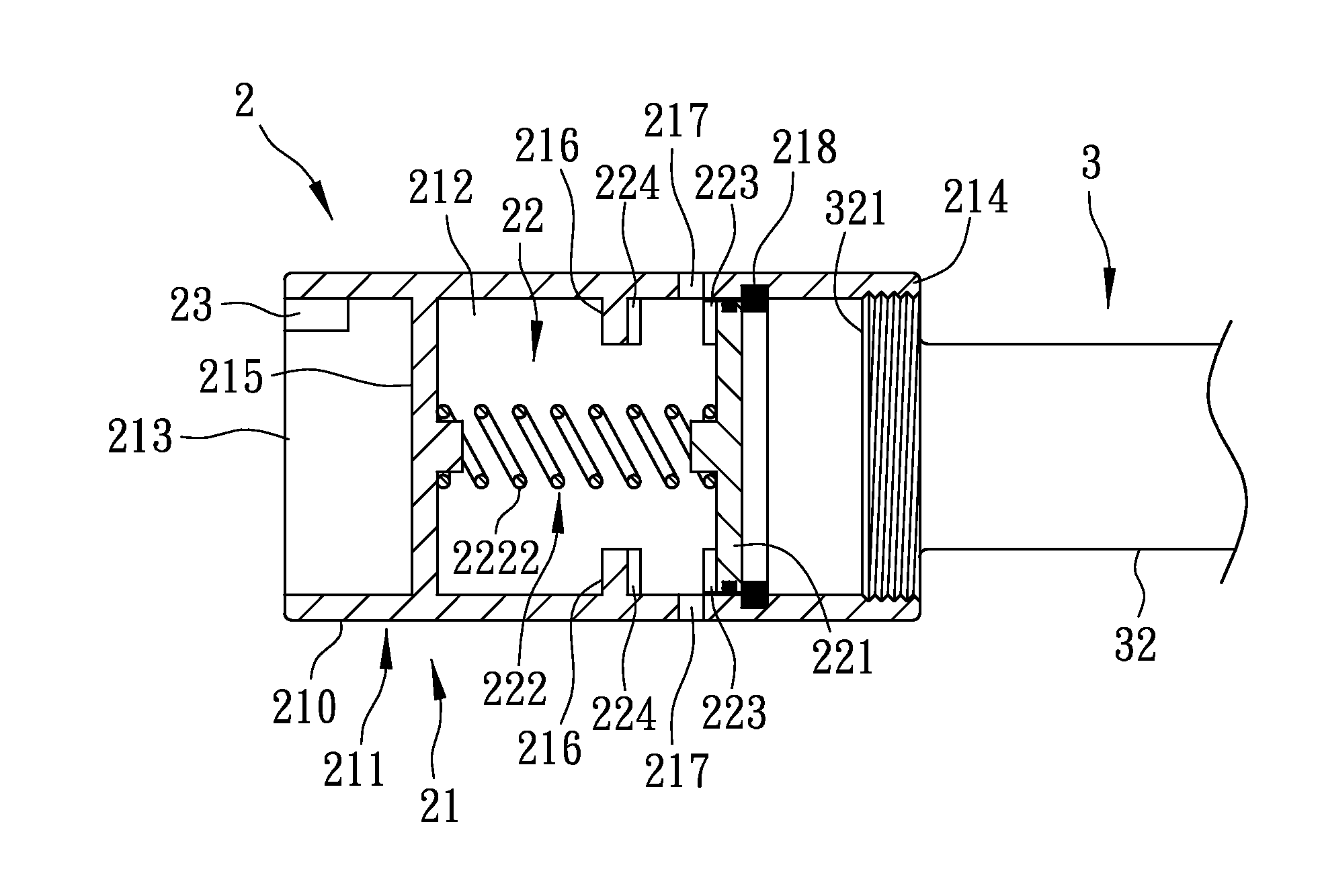

[0034]With further reference to FIG. 5, the laser sight firing device 2 includes a firing unit 21 disposed on the gun barrel 32, a sensing unit 22 disposed in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com