Structured Packing

a structure and packing technology, applied in the direction of liquefaction, separation processes, lighting and heating apparatus, etc., can solve the problems of increasing the pressure drop through the column comprised of the packing, and achieve the effect of reducing cost saving, and increasing the efficiency of mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

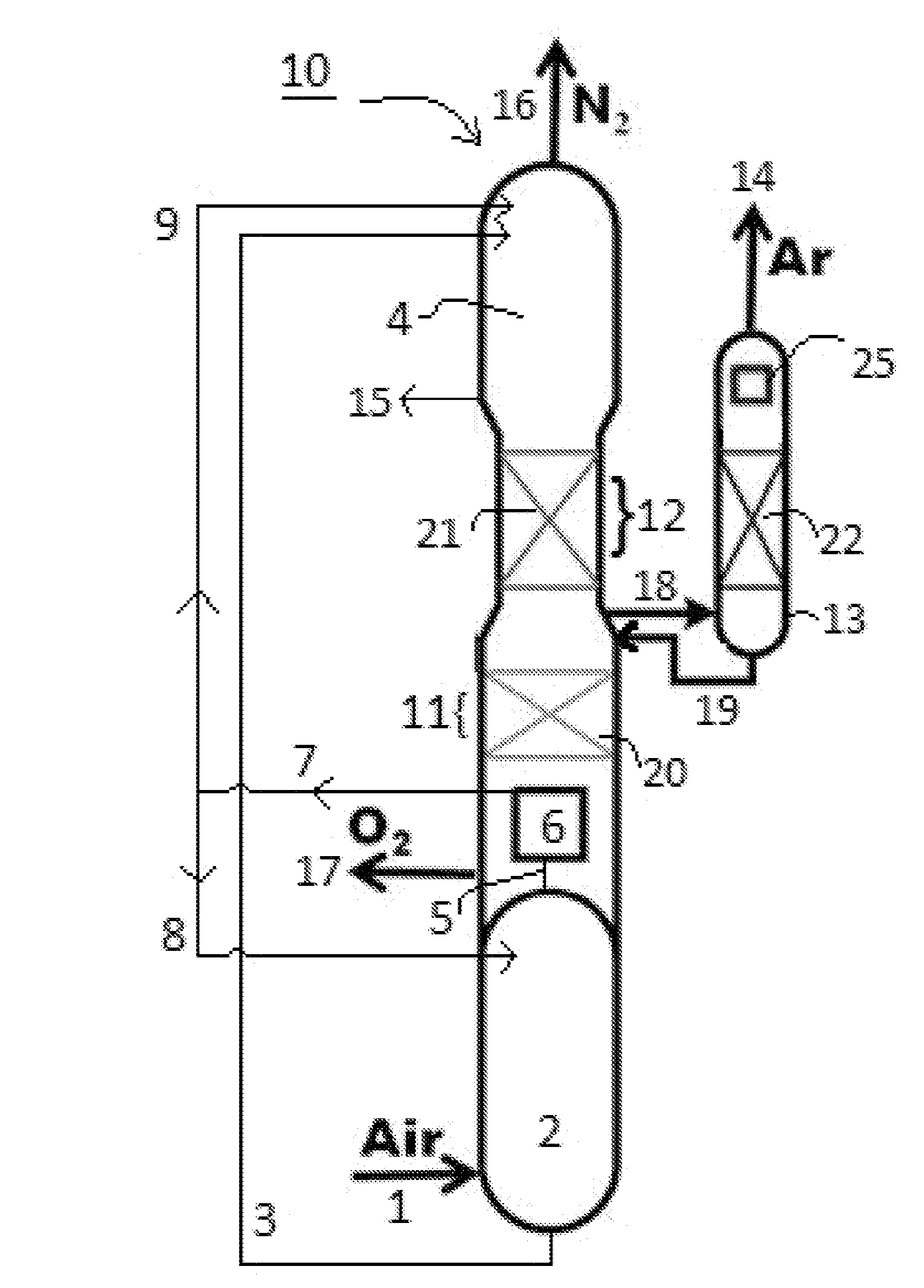

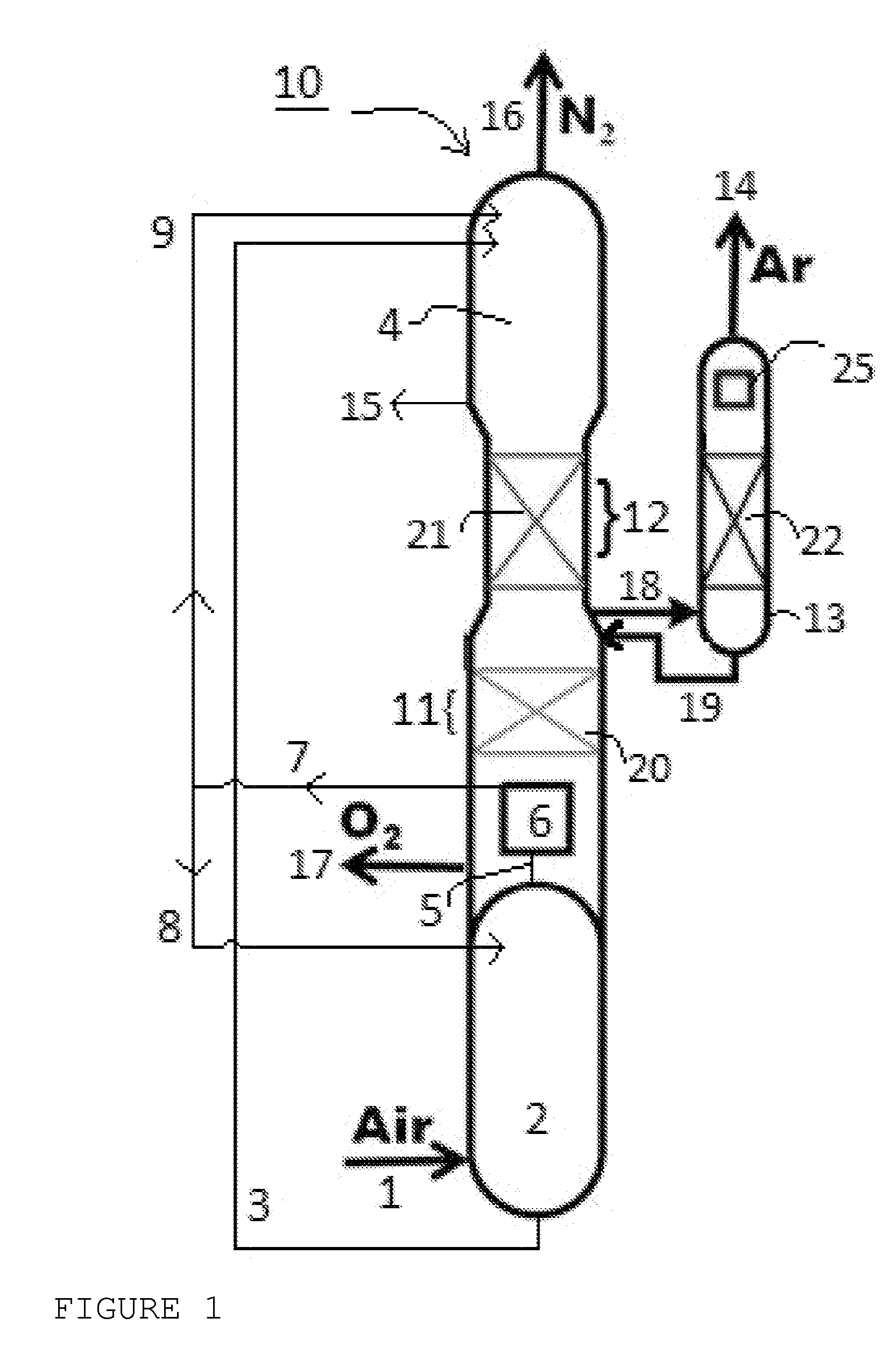

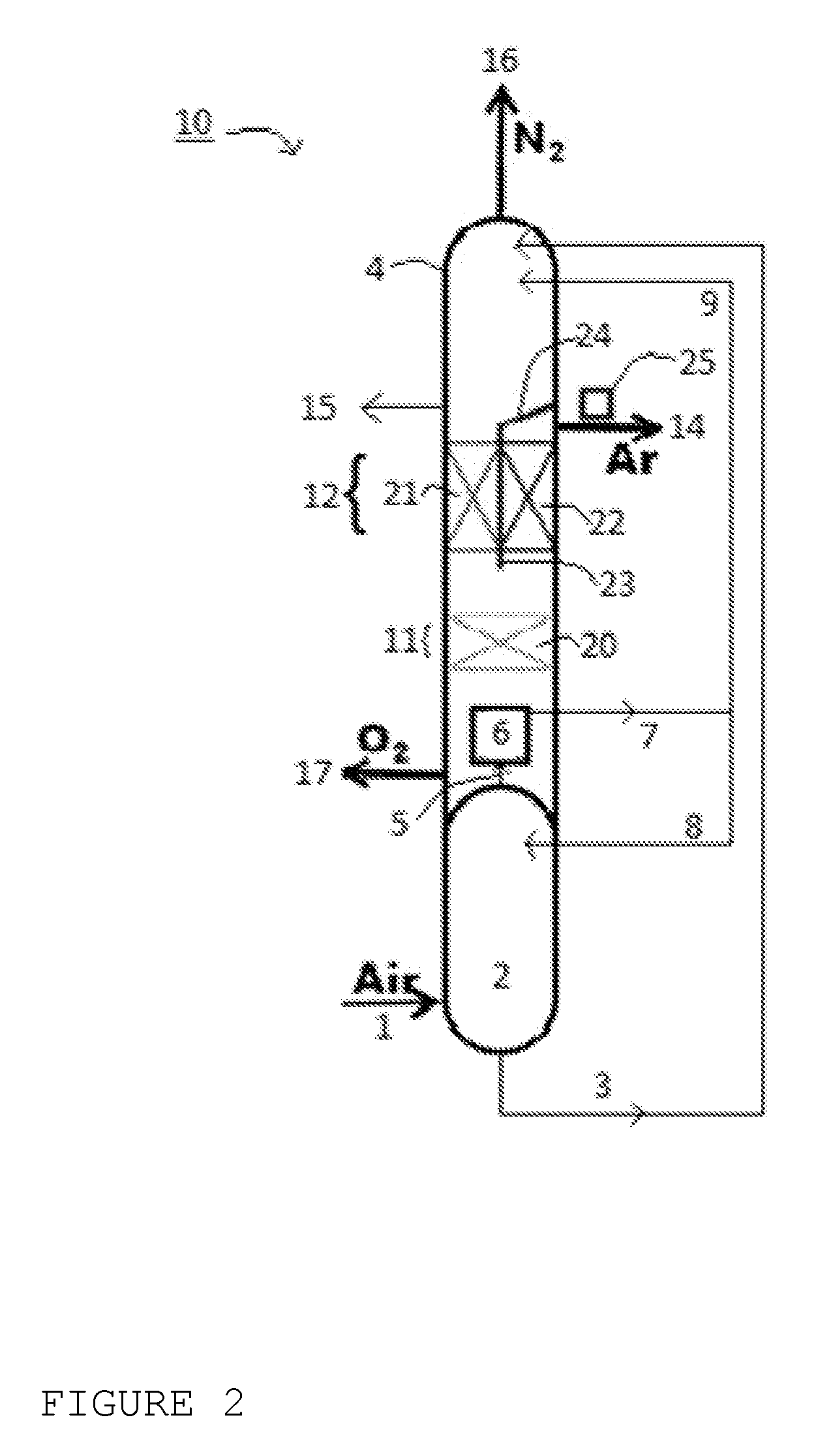

[0075]A comparison of the performance of structured packing according to the prior art with structured packing according to the invention was conducted in a cryogenic distillation apparatus including either a column with a D-shaped cross-section or a column with a circular cross section for the separation of argon from oxygen. For the column with a circular cross section, approximately 20 layers of packing, where each layer of packing is approximately 210 mm in height and 900 mm in diameter, are stacked on top of each other at 90° orientations inside a cryogenic distillation column. For the column with a D-shaped cross-section, approximately 20 layers of packing, where each layer of packing is approximately 210 mm in height and has a 900×450 mm semi-circular area, are stacked on top of each other at 90° orientations inside a cryogenic distillation column. All the comparisons were conducted under total internal reflux at a column pressure of 0.4 barg (40 kPa gauge). The separation of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrugation angle | aaaaa | aaaaa |

| internal angle | aaaaa | aaaaa |

| corrugation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com