Golf ball

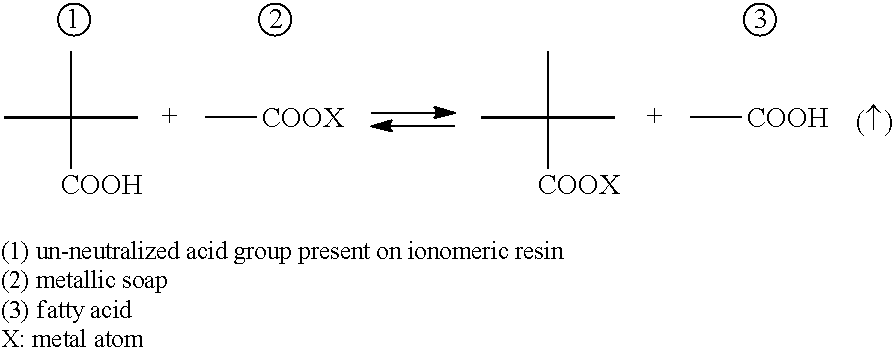

a golf ball and ball technology, applied in the field of golf balls, can solve the problems of reducing the spin rate of the approach shot, unable to achieve durability and a good feel, and unable to meet all of these attributes with only one type of material, and achieves excellent flight performance, good controllability, and suitable spin rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0118]Examples of the invention and Comparative Examples are given below by way of illustration, and not by way of limitation.

examples 1 to 5

, Comparative Examples 1 to 3

Formation of Core

[0119]Solid cores were fabricated by preparing the rubber compositions shown in Table 1 below, then molding and vulcanizing at 155° C. for 15 minutes.

TABLE 1MaterialNo. 1No. 2No. 3FormulationBR 730100100100(pbw)Organic peroxide1.21.21.2Zinc oxide27.1927.8527.47Antioxidant0.10.10.1Zinc acrylate28.2026.4727.62Organosulfur compound0.100.200.00

[0120]Details on each of the ingredients mentioned in Table 1 are given below.[0121]BR730: A polybutadiene rubber synthesized with a neodymium catalyst, available from JSR Corporation under the trade name “BR 730”[0122]Organic peroxide: Available from NOF Corporation under the trade name “Perhexa 3M”[0123]Zinc oxide: Zinc oxide, available from Sakai Chemical Co., Ltd.[0124]Antioxidant: Available from Ouchi Shinko Chemical Industry Co., Ltd. under the trade name “Nocrac NS-6”[0125]Zinc acrylate: vailable from Nihon Jyoryu Kogyo Co., Ltd.

Organosulfur compound:

[0126]The zinc salt of pentachlorothiophenol

F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com