Modular Building System

a modular building and building technology, applied in the field of modular building systems, can solve the problems of inability to offer the flexibility of open space design, finish and precision, and prefab buildings are container-based,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

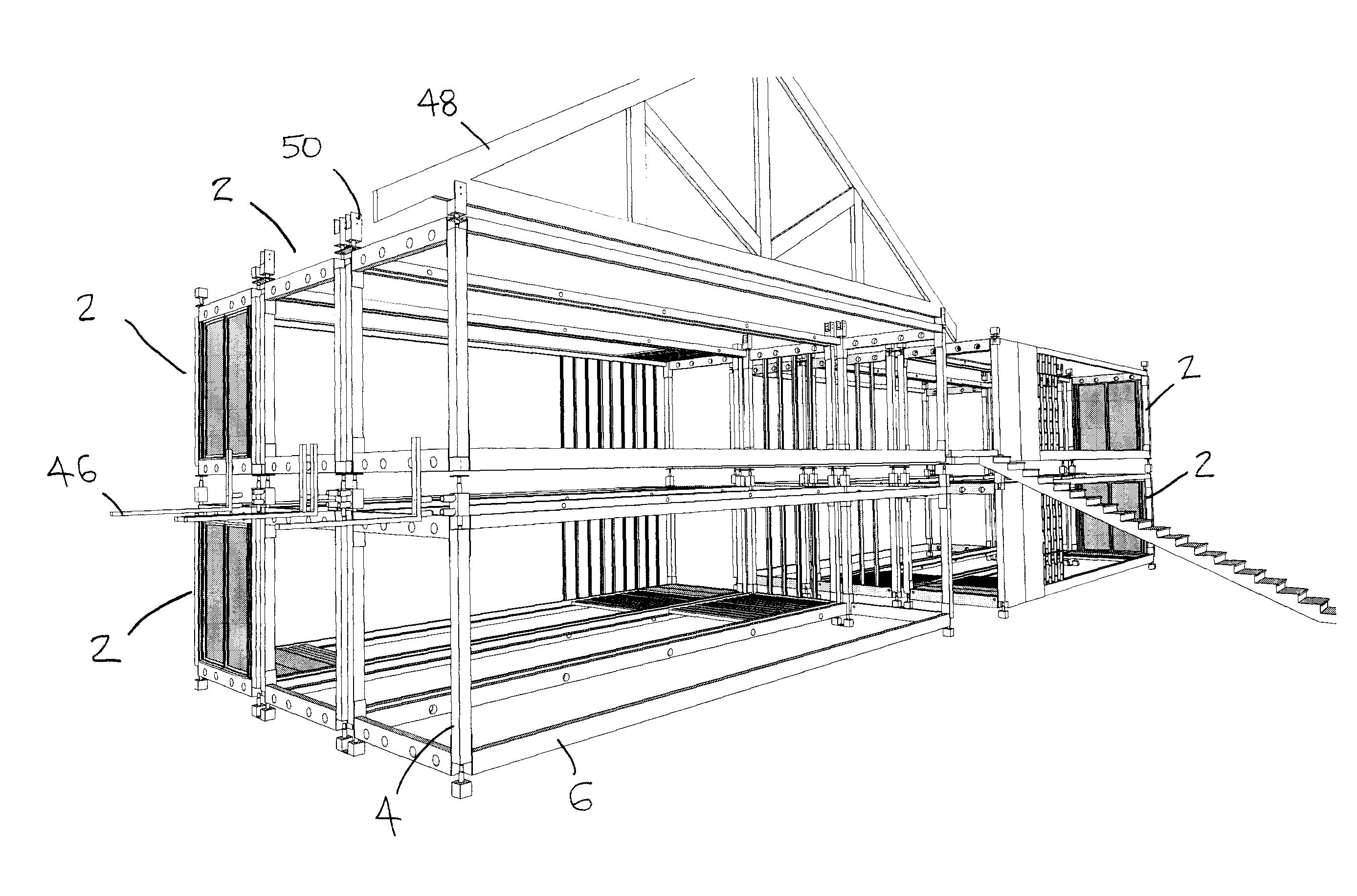

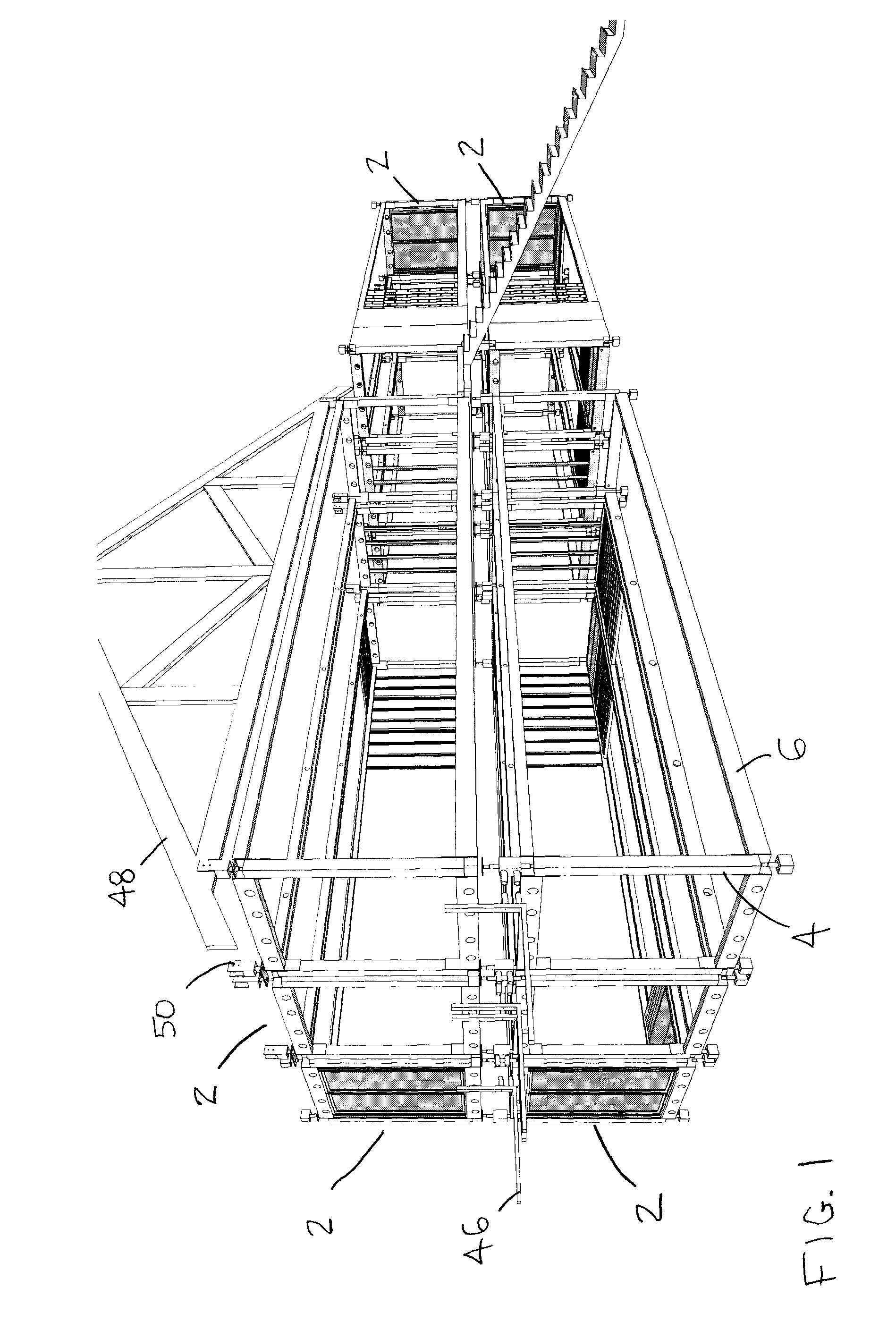

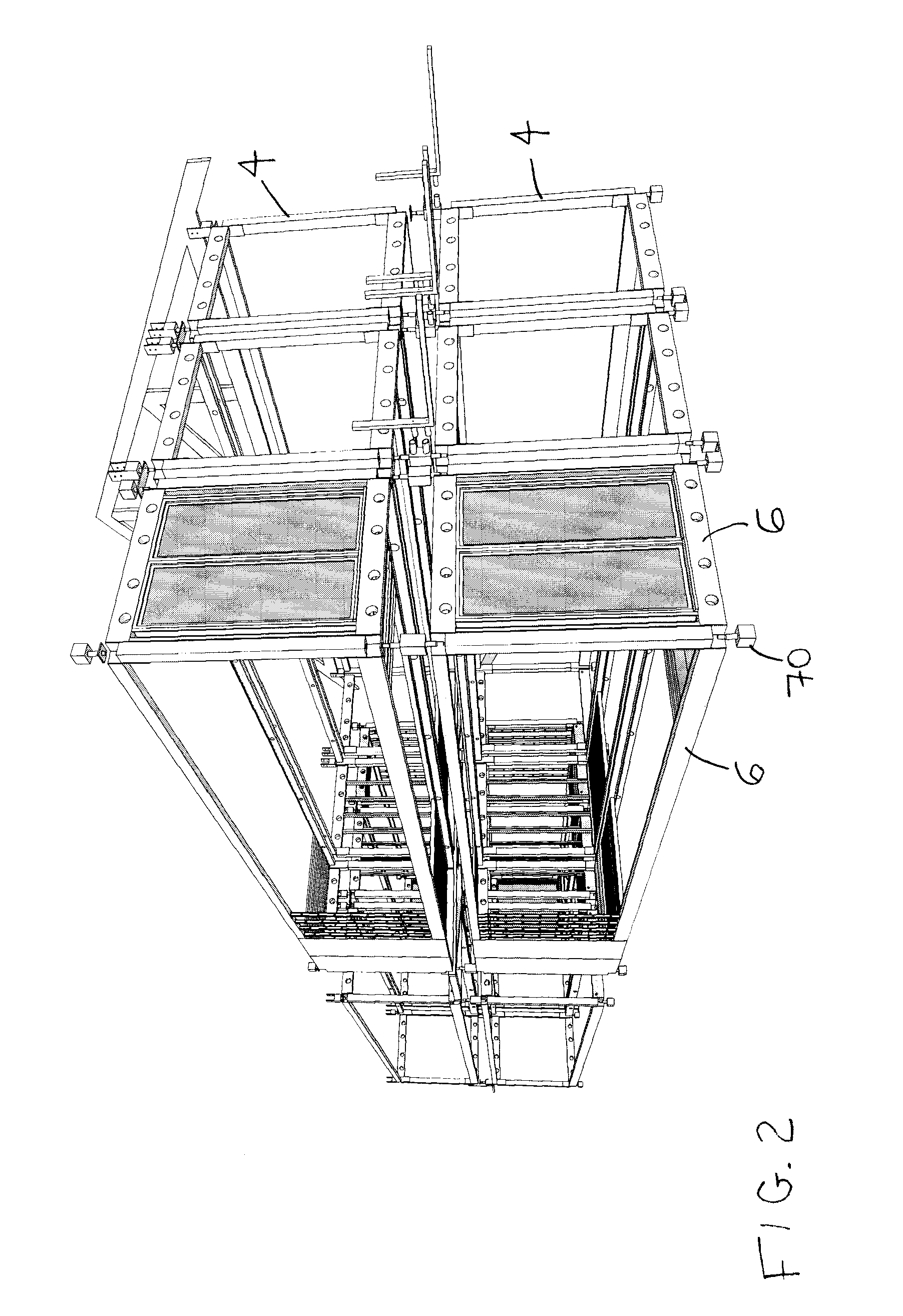

[0095]According to one embodiment of the present invention, there is provided a modular building system comprising individual building modules manufactured and assembled at a manufacturing facility. The modules and related modular components are optimized for transportation, and are transported to a building site by conventional ocean, rail, air and truck delivery systems using temporarily attached standard ISO shipping adaptors. Once on site, the modules may be modularly assembled into conventional-looking buildings.

[0096]The individual modules are the core units of the modular building system of the present invention. Buildings may be assembled by attaching together a plurality of the structurally self-supporting modules. The modules may be attached horizontally adjacent to one another, stacked vertically above and below one another, or both horizontally attached and vertically stacked using a variety of specialized, interchangeable adaptors between adjacent and stacked modules. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com