Method for Improving Rheological Properties of Mineral Slurry

a technology of mineral slurry and rheological properties, which is applied in the direction of silicon compounds, grain treatment, silicates, etc., can solve the problems of reducing the yield and operation efficiency, the difficulty of separation of nickel minerals from serpentinite-containing gangue, and the cost of nickel recovery losses, so as to reduce the viscosity of the slurry and increase the flotation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

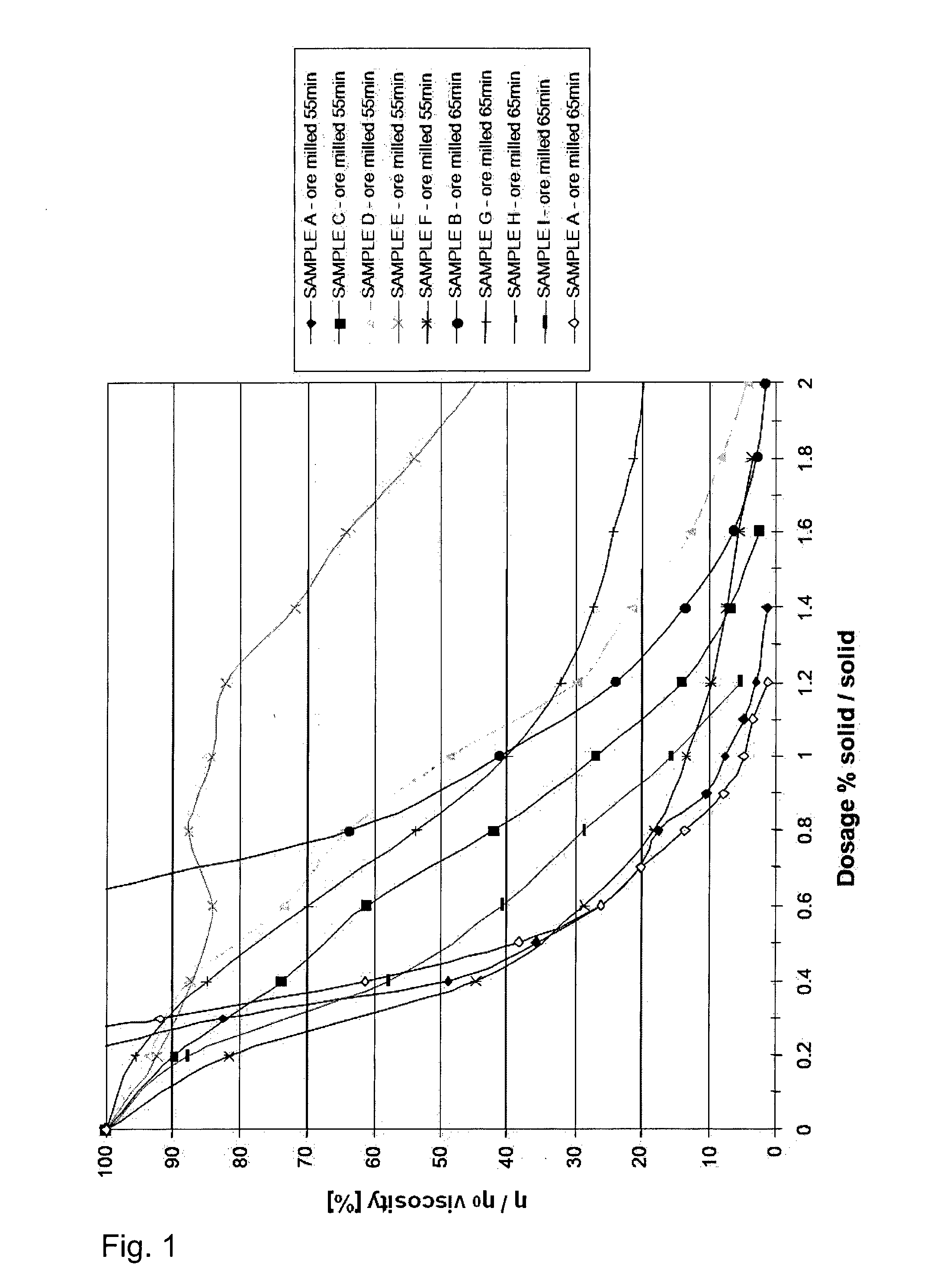

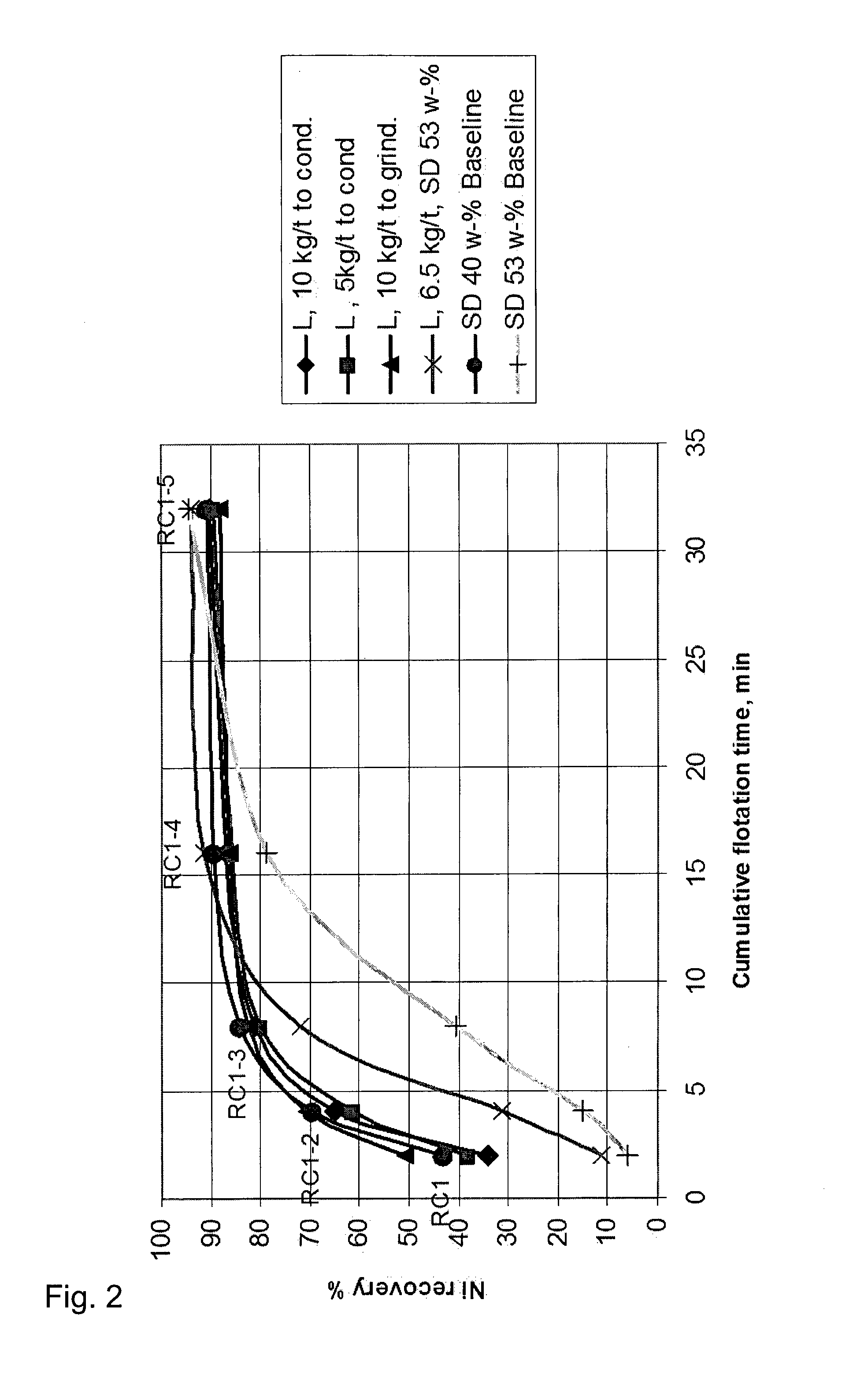

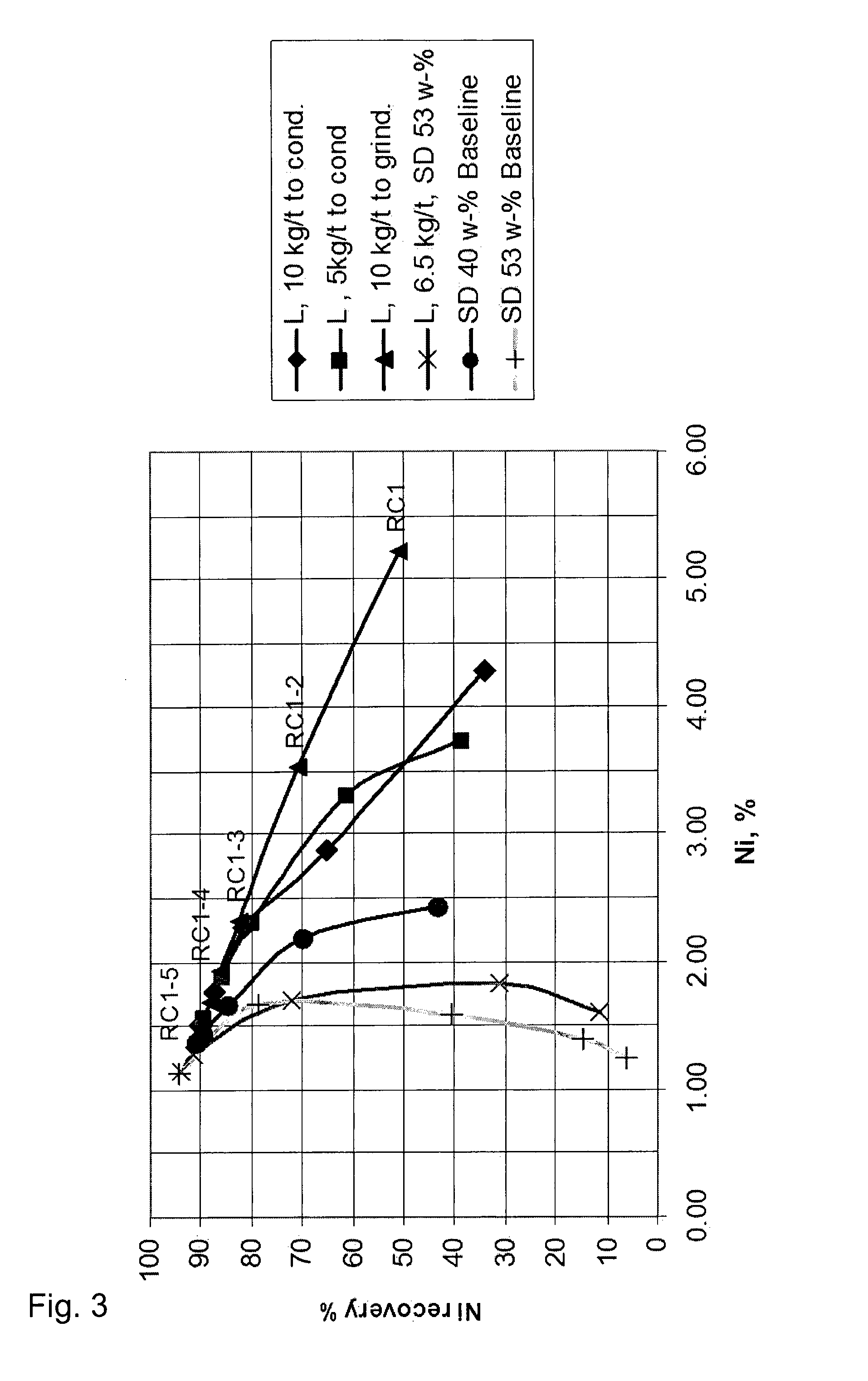

[0043]The test program consisted of viscosity measurements and flotation tests. Hitura serpentinite sample (Ni 0.73%) was the main test material of the study. Totally nine dispersive reagents were selected for the rheological studies and flotation tests were done using four the most effective reagents (A, F, I and L).

[0044]Viscosity measurements were done with Brookfield viscometer RVDV-I. Temperature was recorded, but not controlled. Temperature varied between 21-23t. Viscosity was measured with two spindle speed (50 rpm and 100 rpm) according to internal laboratory method used for mineral pastes i.e. coating pastes having solid content up to 60-65 w-%. Slurry volume in measurements was constant 250 ml. Slurry preparation was done with DIAF 20VH mixer.

[0045]Milled ore and ion-exchanged water was mixed for 10 min before addition of dispersant. After the dosage slurry was mixed for 5 min before viscosity measurement.

[0046]The dispersants tested were the following:

[0047]A—AA / AMPS

[0048...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com