Cane and Cylindrical Body

a cylindrical body and cane technology, applied in the field of canes, can solve the problems of unsatisfactory strength, unsatisfactory conventional wooden canes, and heavy burden on users, and achieve the effects of reducing the cost of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

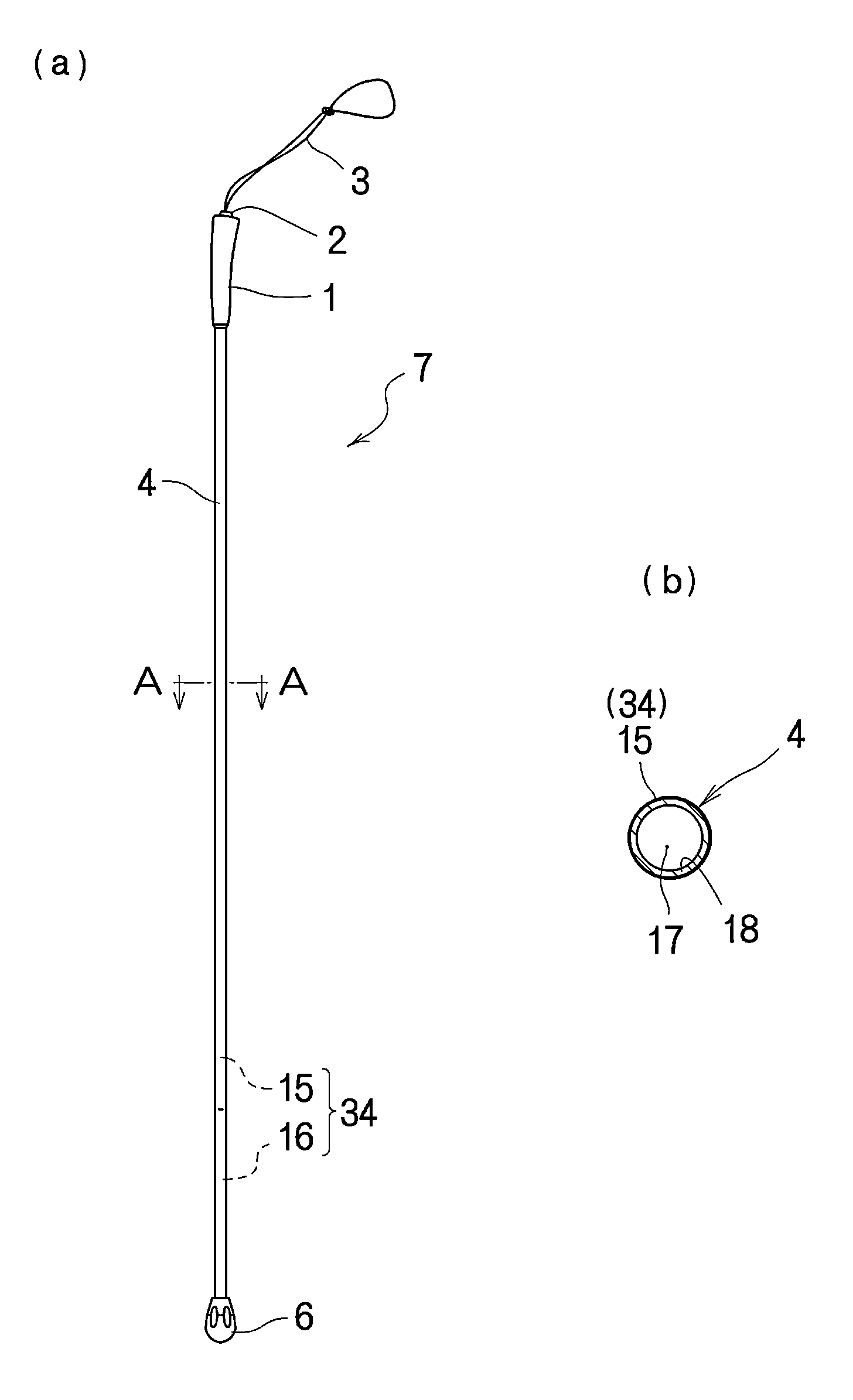

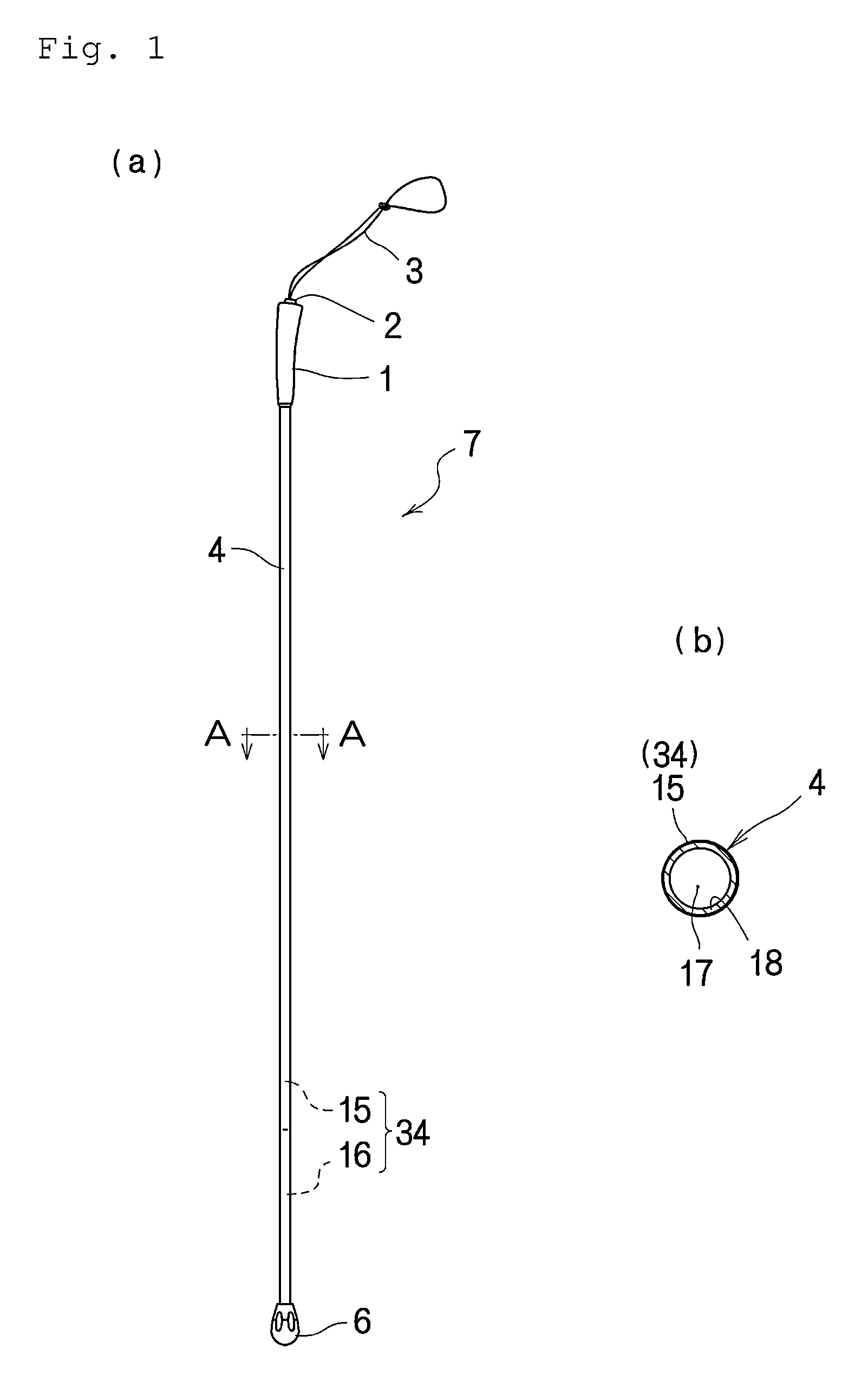

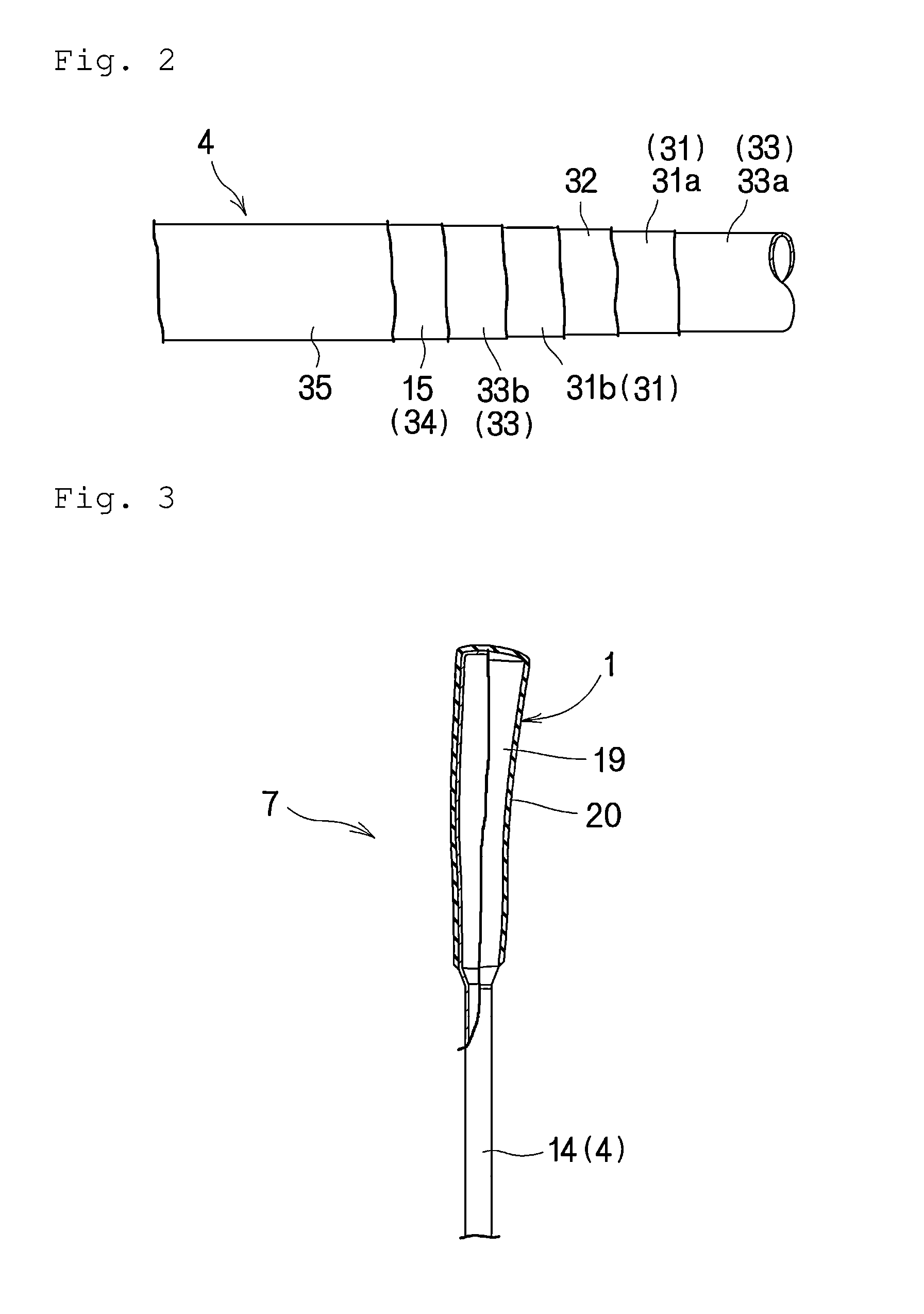

Image

Examples

example 1

[0116]As a high-strength organic fiber, a poly(p-phenylene terephthalamide) fiber, KEVLAR K-29 1670 dtx (manufactured by DU PONT-TORAY CO., LTD.) was used. From this organic fiber, a unidirectional (UD) sheet with a fiber areal weight of 73 g / m2 was prepared, and the sheet was impregnated with an epoxy resin by a hot melt method in such a manner that the fiber-resin content ratio might be 67:33. In this way, a high-strength organic fiber prepreg with a fiber areal weight of 110 g / m2 was obtained. As a carbon fiber prepreg, TORAYCA (registered trademark) prepregs (type: 9052S-17 and 3252S-05, manufactured by Toray Industries, Inc.) were used. Each of these prepregs is a carbon fiber prepreg with a fiber areal weight of 330 g / m2 and is produced by impregnating a UD sheet with a fiber areal weight of 220 g / m2 with an epoxy resin in such a manner that the fiber-resin content ratio may be 67:33.

[0117]As a glass fiber, a glass fabric, WPA-240D (manufactured by Nitto Boseki Co., Ltd.), whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com