Variable displacement pump

a variable-discharge, pump technology, applied in the direction of pump control, positive-discharge liquid engine, rotary piston liquid engine, etc., can solve the problems of large electric energy loss, inability to obtain high pressure characteristic in the low engine speed region, etc., to reduce electric energy loss, high pressure characteristic, high pressure characteristic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

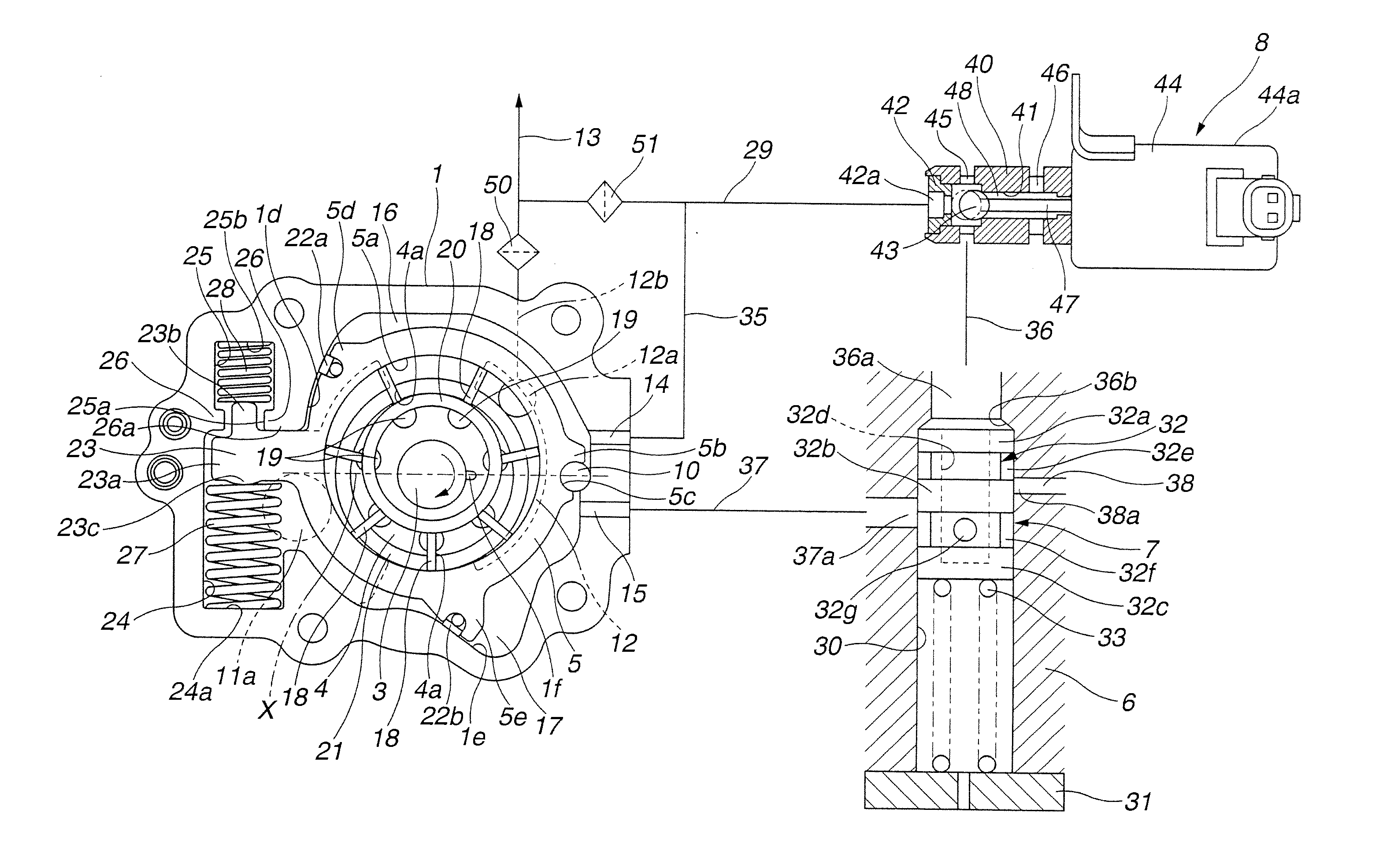

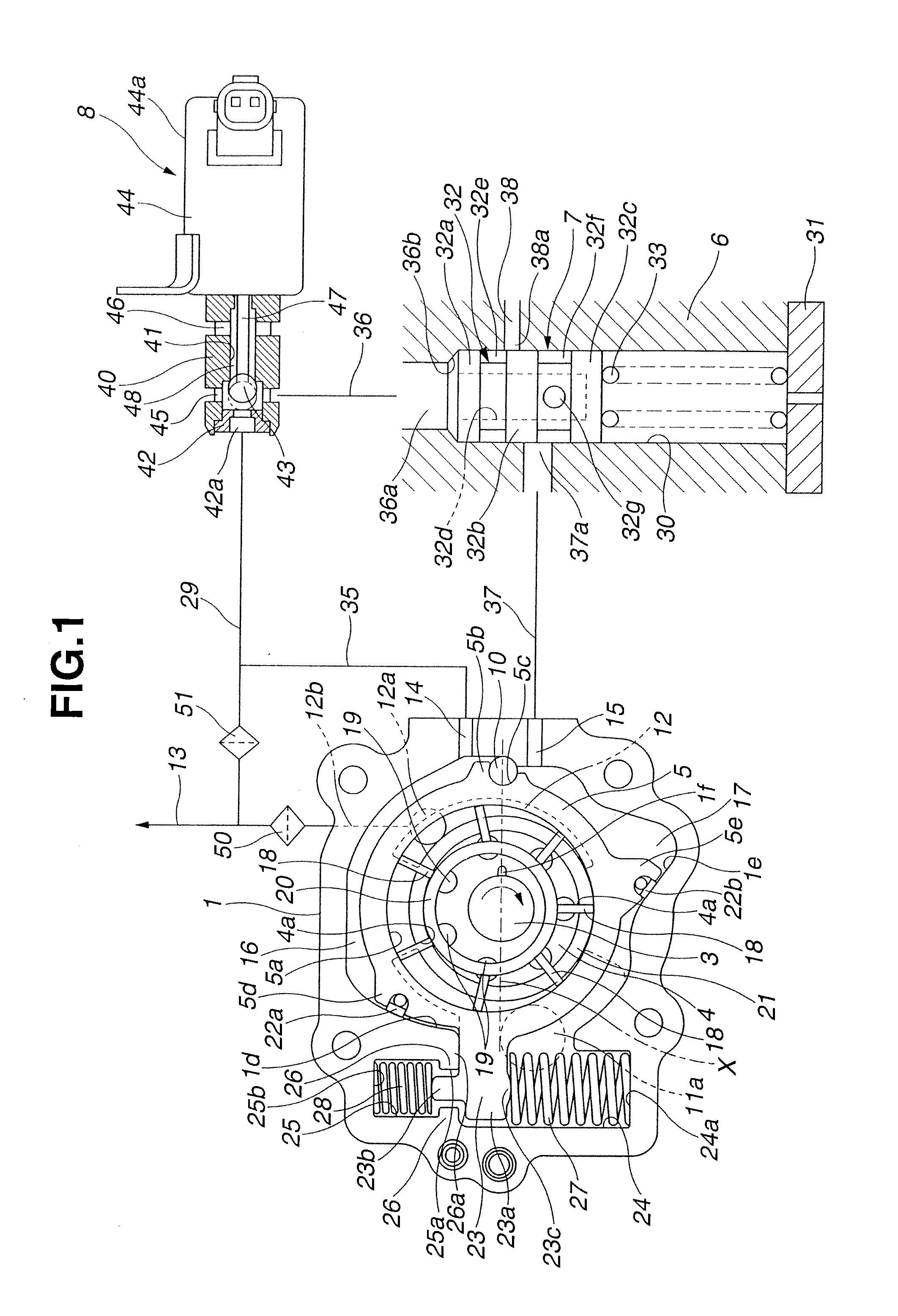

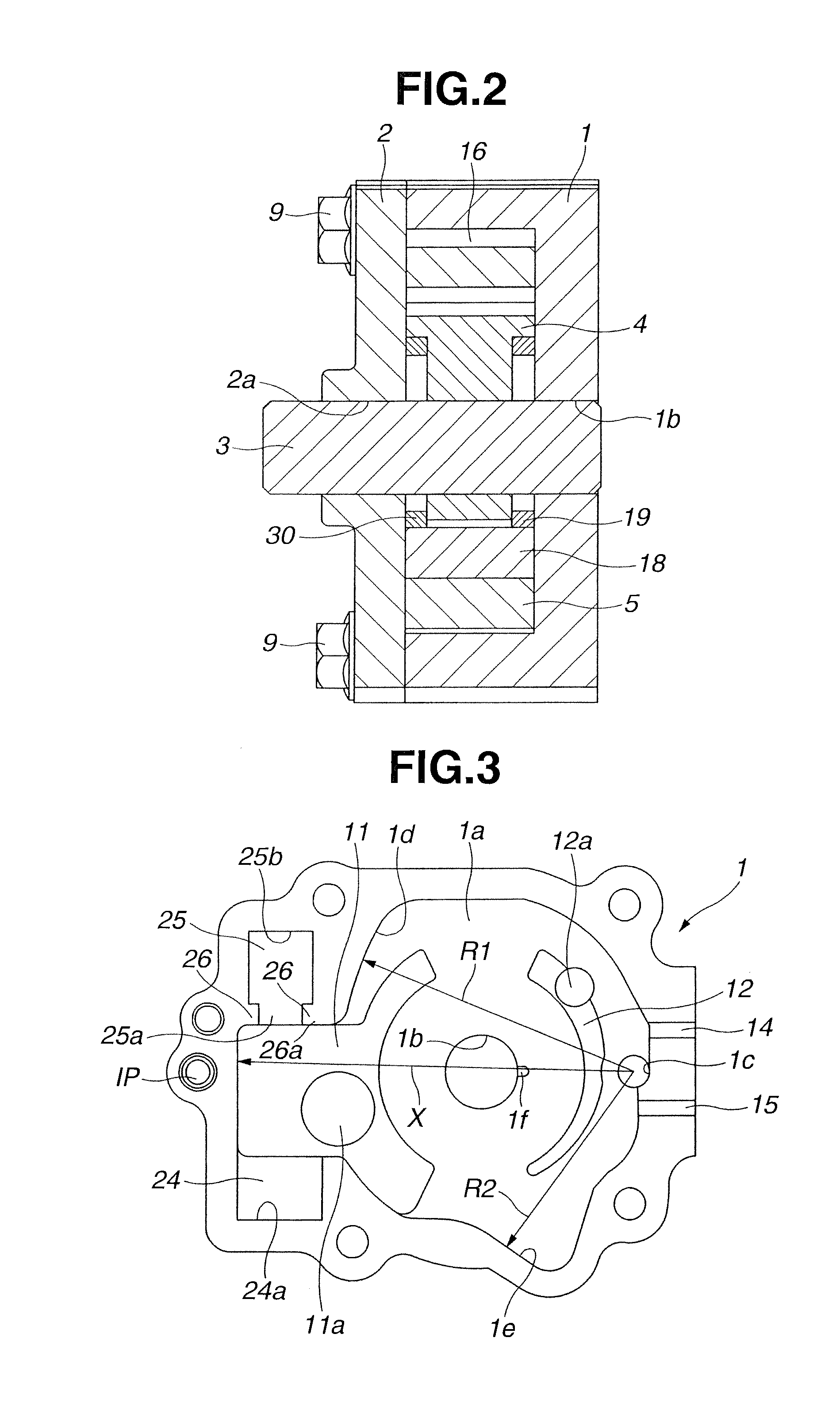

[0027]The variable displacement pump according to the first embodiment of the present invention includes a pump main body of a vane type. The variable displacement pump is provided to a front end portion of a cylinder block of an internal combustion engine. As shown in FIGS. 1 and 2, the variable displacement pump includes a pump housing 1 which includes one end opening that is closed by a pump cover 2, and the other bottomed end portion; a drive shaft 3 which penetrates through a substantially center portion of pump housing 1, and which is driven by the crank shaft of the engine; a rotor 4 which has a substantially H-shaped cross section, which is rotationally received within pump housing 1, and which includes a center portion connected with drive shaft 3; and a cam ring 5 which is a movable member that is swingably disposed radially outside rotor 4.

[0028]Moreover, the variable displacement pump includes a control housing 6 which is made from an aluminum alloy, and which is dispose...

second embodiment

[0131]FIG. 9 shows a variable displacement pump according to a second embodiment of the present invention. The structure of the pump main body and the structure of electromagnetic switching valve 8 in the variable displacement pump according to the second embodiment of the present invention are substantially identical to those of the variable displacement pump according to the first embodiment in most aspects as shown by the use of the same reference numerals. Accordingly, the repetitive illustrations are omitted. In the variable displacement pump according to the second embodiment of the present invention, a structure of pilot valve 7 and structures of the passages are different from those of the variable displacement pump according to the first embodiment. Therefore, hereinafter, these are illustrated.

[0132]That is, in pilot valve 7, sliding hole 30, and drain passage 38 having one end opening 38a formed in sliding hole 30 are formed within control housing 6. Siding hole 30 is for...

third embodiment

[0146]FIGS. 11-14 show a variable displacement pump according to a third embodiment of the present invention. In this third embodiment, first control hydraulic chamber 16 and a second control hydraulic chamber 57 do not sandwich pivot pin 10. First control hydraulic chamber 16 and second control hydraulic chamber 57 are disposed in parallel with each other on the upper side of pivot pin 10 in FIG. 11. Accordingly, when the hydraulic pressure is introduced into either of control hydraulic chambers 16 and 57, the eccentric amount of cam ring 5 is decreased, and the pump capacity is decreased.

[0147]Moreover, main oil gallery 13 is constantly connected through connection passage 35 to first control hydraulic chamber 16, and connected through first branch passage 29 to solenoid opening port 42a of electromagnetic switching valve 8. Furthermore, main oil gallery 13 is connected through a second branch passage 59 to a downstream side opening end 59a of pilot valve 7.

[0148]Arm 23 of cam rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com