Turbocharger with a double-vane nozzle system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment i

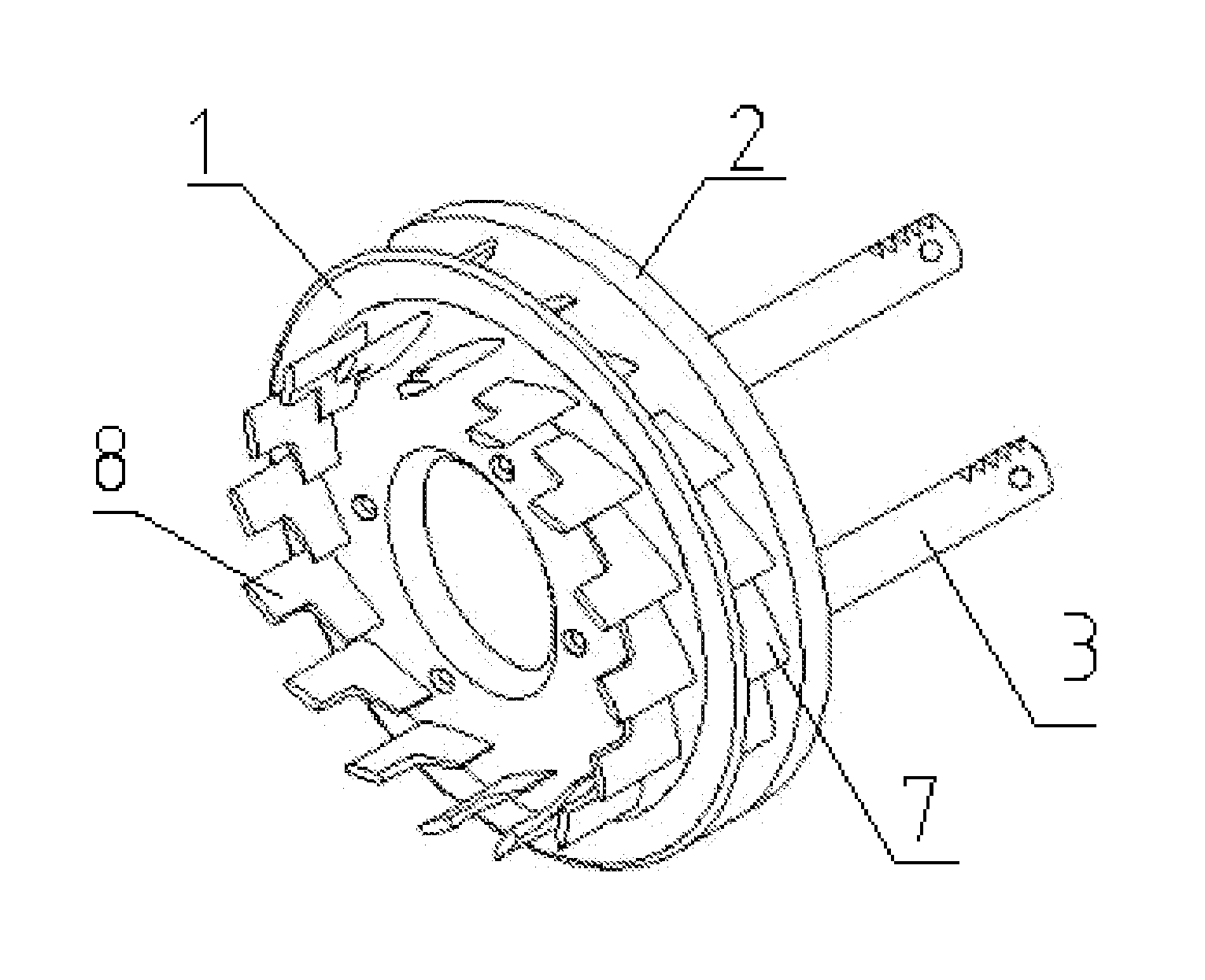

[0026]It is given that there are eight fixed vanes 8 and eight moving blades 7, and the intake angle of the blade, i.e. the blade incidence is 21 degree.

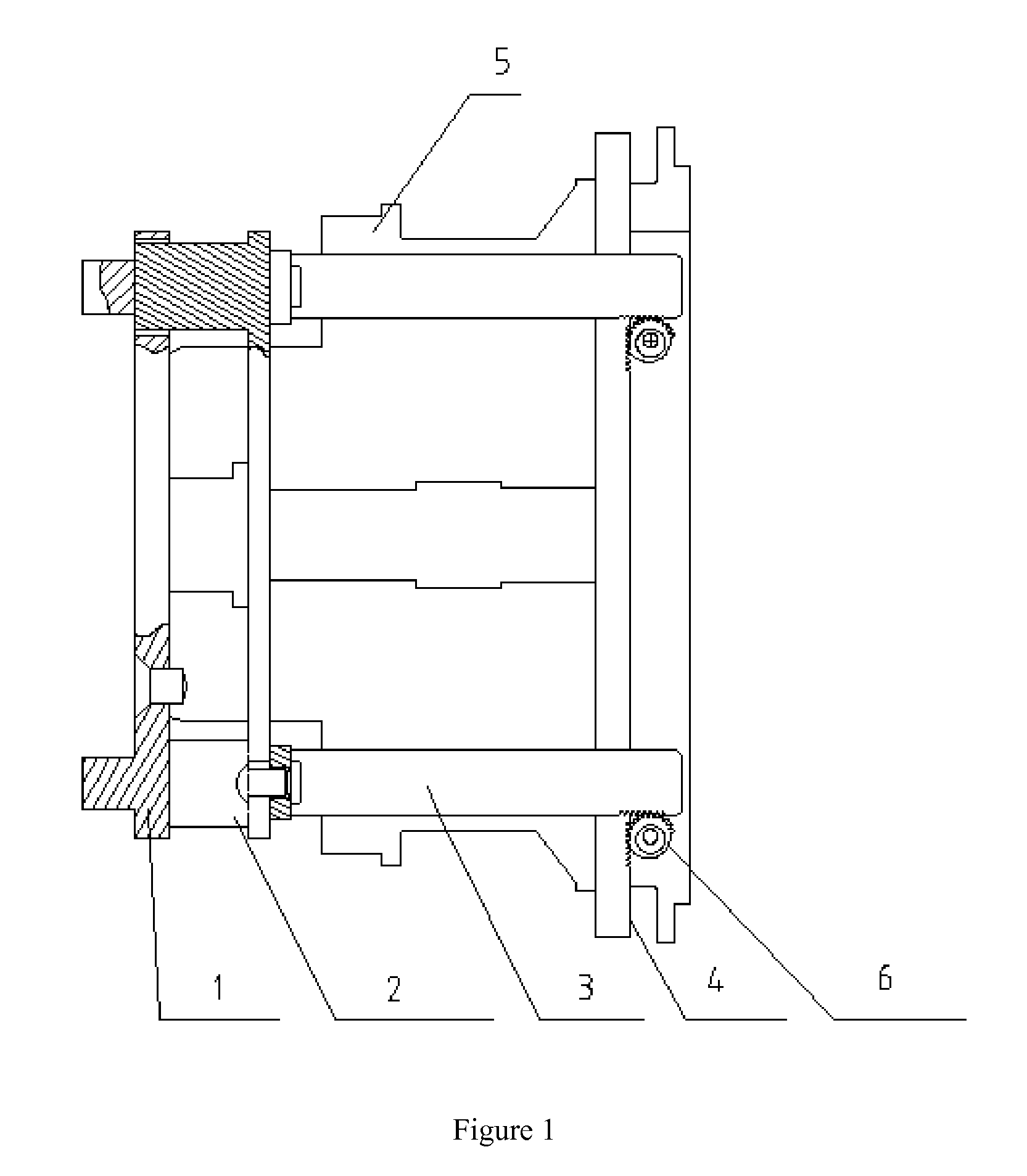

[0027]As shown in FIGS. 1, 4, and 10, a group of airfoil fixed vane 8 are provided on the front end face of the fixed nozzle ring 1, blade-shaped holes 9 are arranged between the fixed vanes 8, the fixed nozzle ring 1 is provided with a center hole at the center and sheathed around the circumference of the middle-housing 5 and fixed to the middle-housing 5 via screws, a linearly moving nozzle disk 2 is mounted on the rear end of the fixed nozzle ring 1.

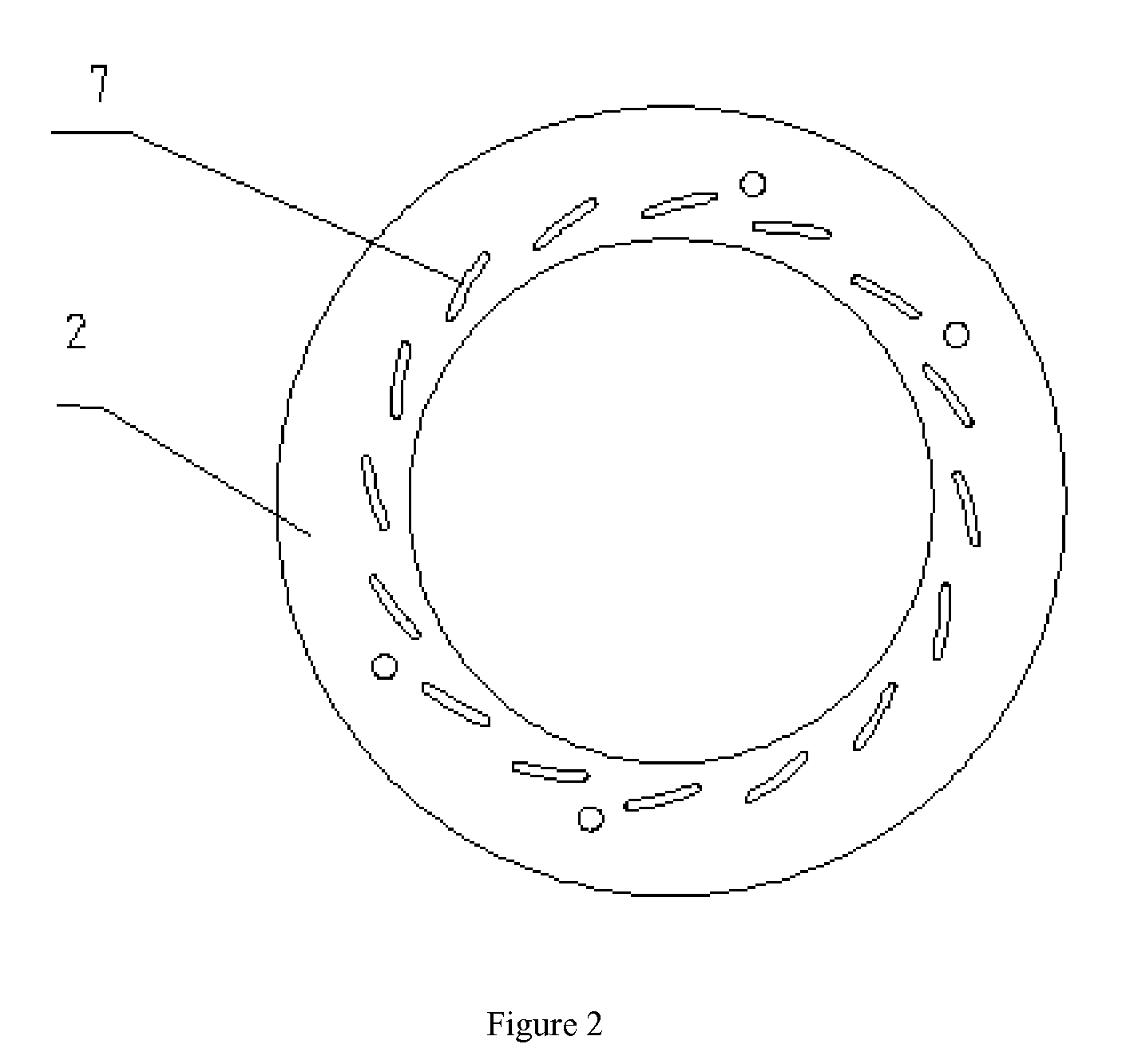

[0028]As shown in FIGS. 2 and 10, a group of moving blades 7 are provided on the front end face of the linearly moving nozzle disk 2, the shape of the moving blade 7 is consistent with that of the blade-shaped hole 9, the moving blades 7 are moveably inserted into the blade-shaped holes 9.

[0029]As shown as in FIGS. 1, 5, 6, and 10, two rocker arm rods 3 are fixed to the rear end face ...

embodiment ii

[0035]The difference between the present embodiment II and the embodiment I is that the driving device pushing the rack upward and downward is a solenoid valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com