Apparatus and method for generating a layer system

a layer system and apparatus technology, applied in the direction of molten spray coating, coating, plasma technique, etc., can solve the problems of laborious additional processes, limited method specificity of known techniques, and reduced protective effect of reactive media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

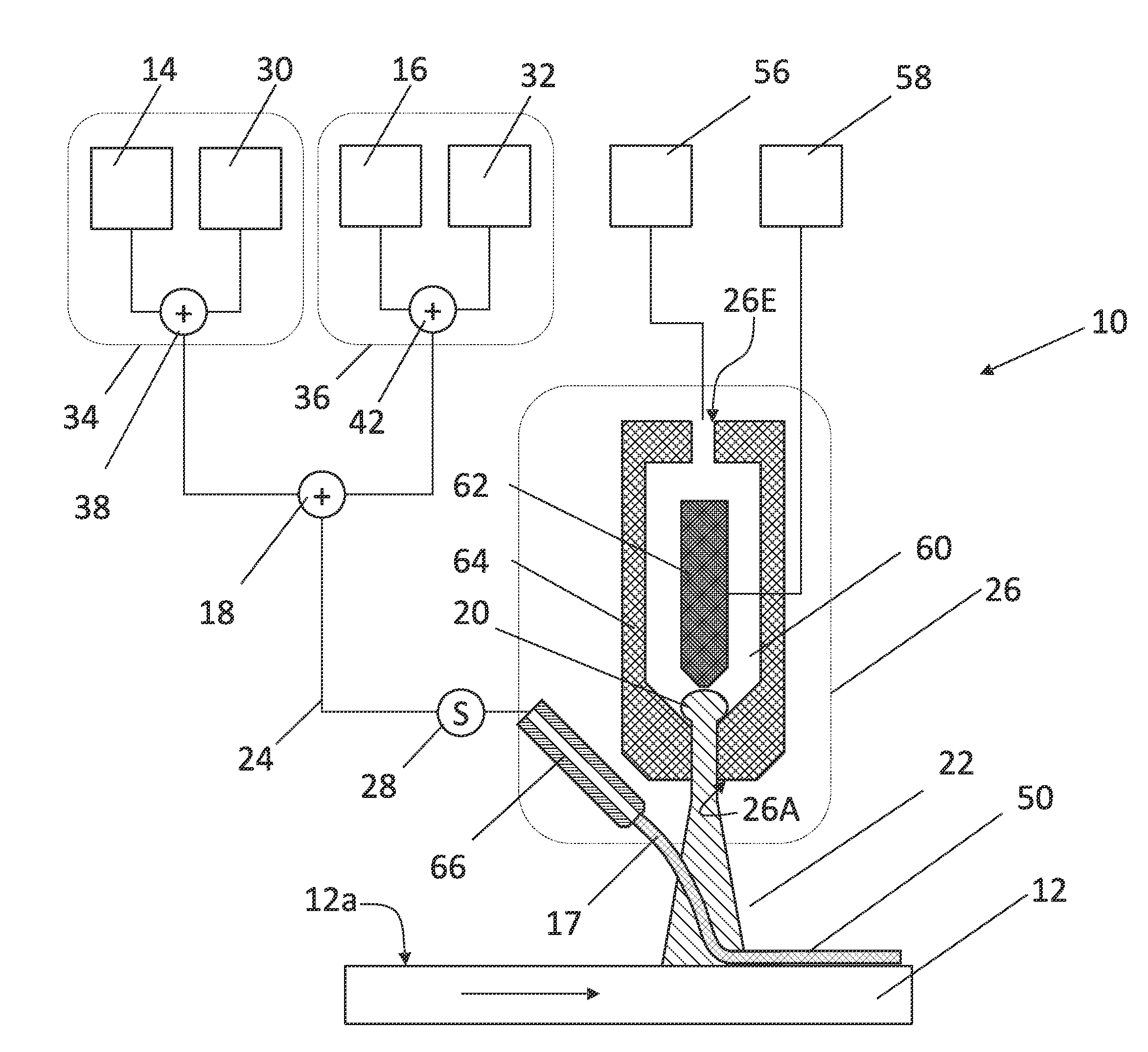

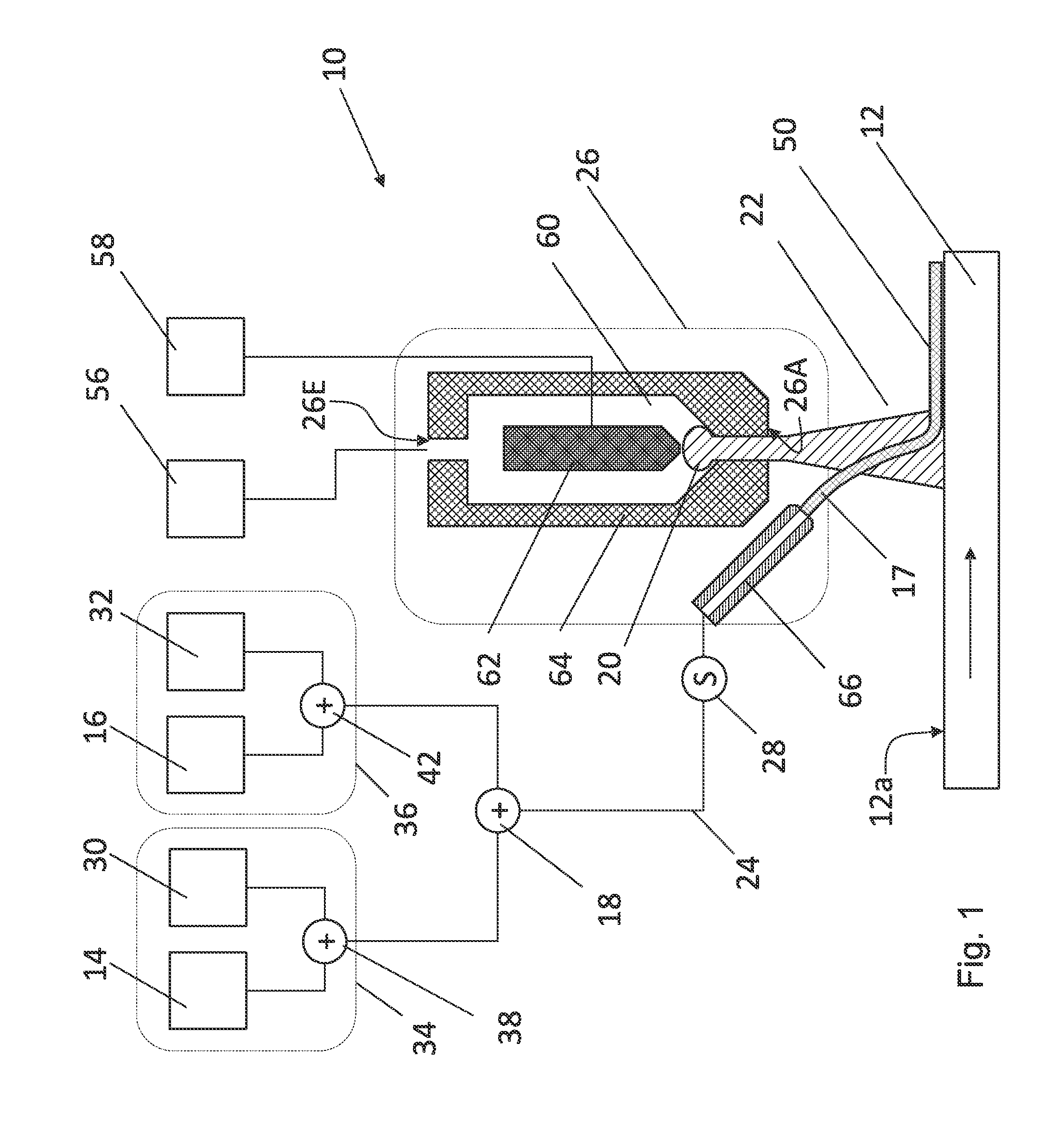

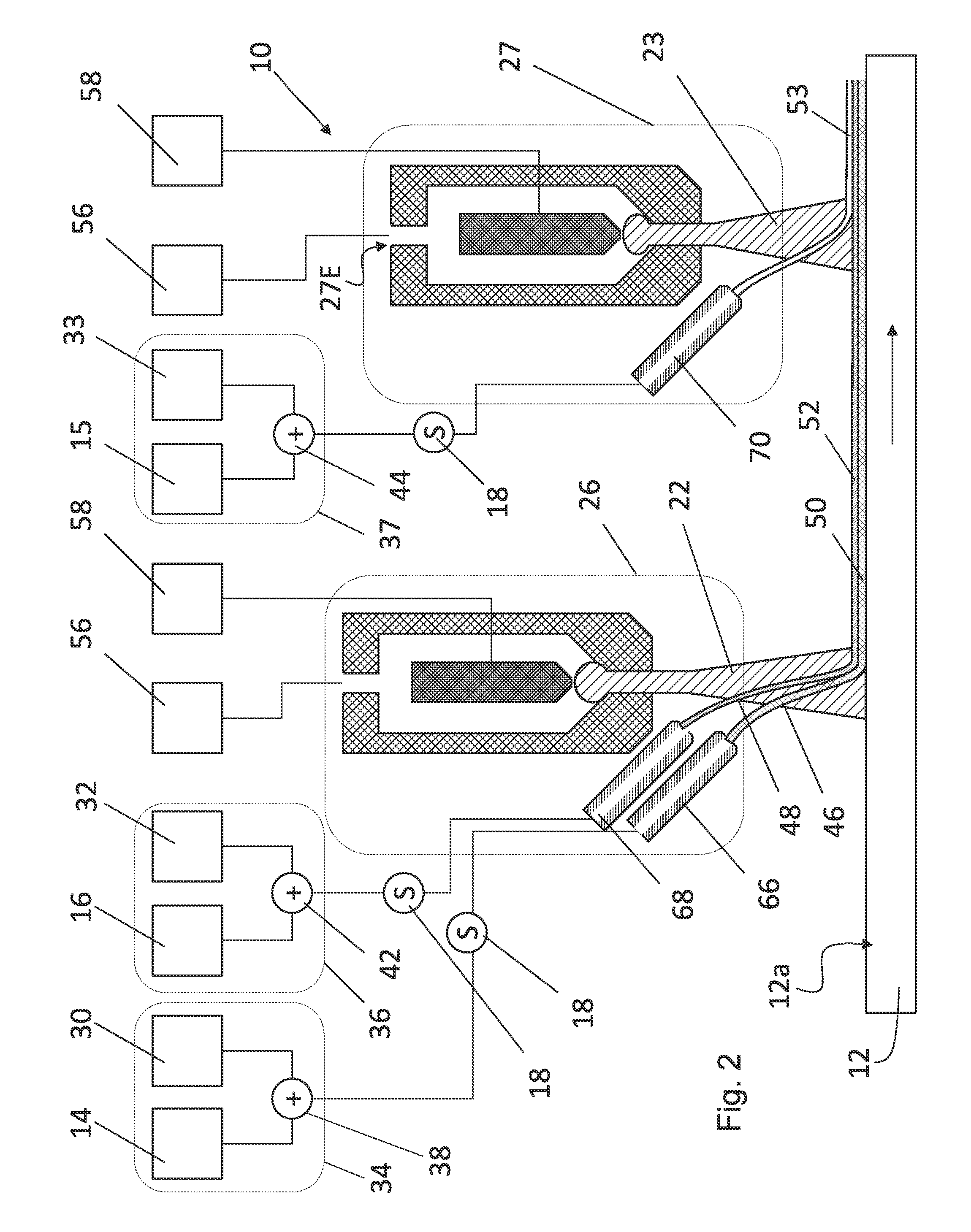

[0039]FIG. 1 schematically shows a coating apparatus 10 for coating a substrate The coating apparatus 10 has a plasma module with a coating head 26, a source for a plasma process gas 56 and a power supply 58.

[0040]The coating head 26 has a plasma chamber 60 in which an electric arc 20 is started between two electrodes 62 and 64. Electrical energy is supplied to this electric arc 20 from the power supply 58 for sustaining it, so that, depending on the modulation of the power supply 58, a continuous plasma jet 22 or a pulsed plasma jet 22 is generated, which exits on the exit side 26A of the coating head 26. At the feed side 26E of the coating head 26 a plasma process gas 56 may be supplied, so that the plasma process gas 56 streams through the plasma chamber 60 in a controlled manner. A mixture of process gas 30, 32 and particles may be supplied to the plasma jet 22 via an injector 66, which here is shown as an external injector. The particles may be partially molten by the high ener...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| corrosive | aaaaa | aaaaa |

| thermal | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com