Emulsion explosive sensitising

a technology of emulsion explosives and sensitisation, which is applied in the direction of explosives, non-explosive/non-thermal compositions, weapons, etc., can solve the problems of uncontrollable gassing rate, increased cost, and required modification of equipmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

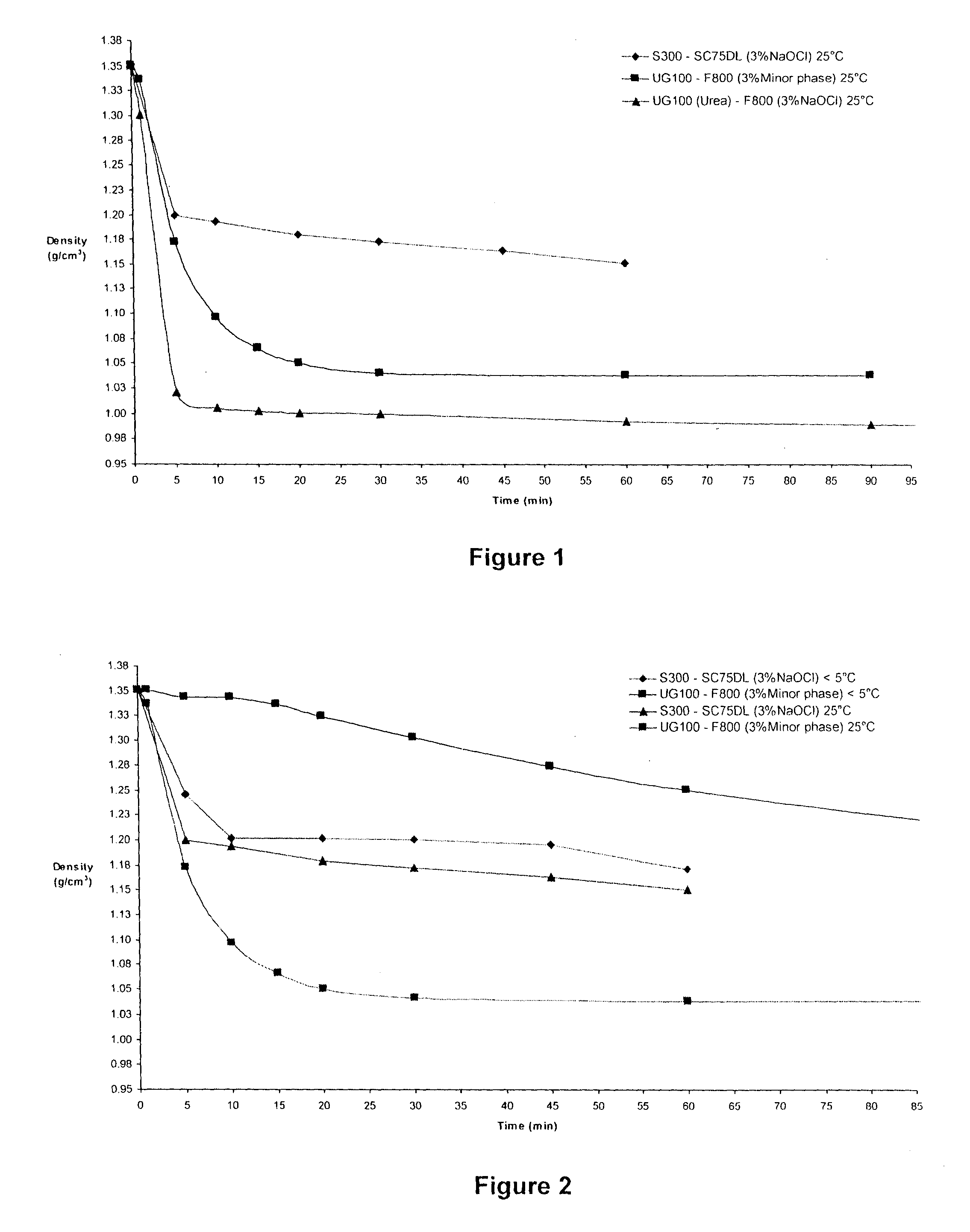

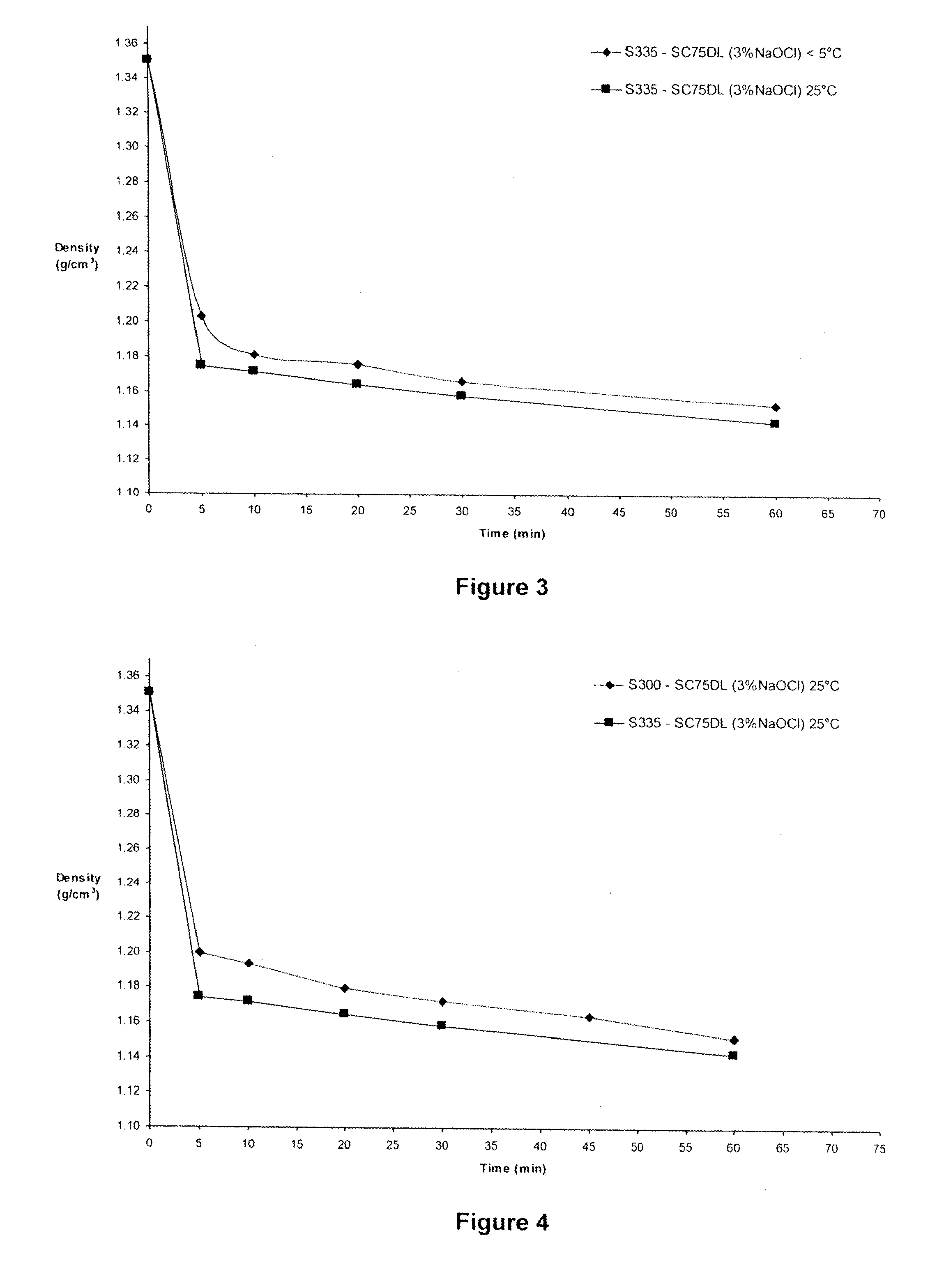

[0024]One aspect of the invention is based on the realisation that the fuel phase composition of the emulsion determines the gassing rate and performance of the final product. The surfactant constitutes approximately 20% of the fuel phase and forms an integral part in a barrier between the oxidising solution and the gassing solution.

[0025]Basic head groups on the PIBSA (poly-isobutylene succinic anhydride) surfactant have been used successfully in providing additional stability to the emulsion when oxidiser quality is a problem. These surfactants however have drawbacks in that a sodium nitrite gassing system does not provide sensitisation under normal operating conditions. The independence of a sodium hypochlorite gassing system to pH provides a suitable alternative for sensitising an emulsion system without requiring fundamental changes to operating procedures or equipment.

[0026]In the present invention use is made of a surfactant composition that contains a different surfactant he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com