Multi-mode filter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

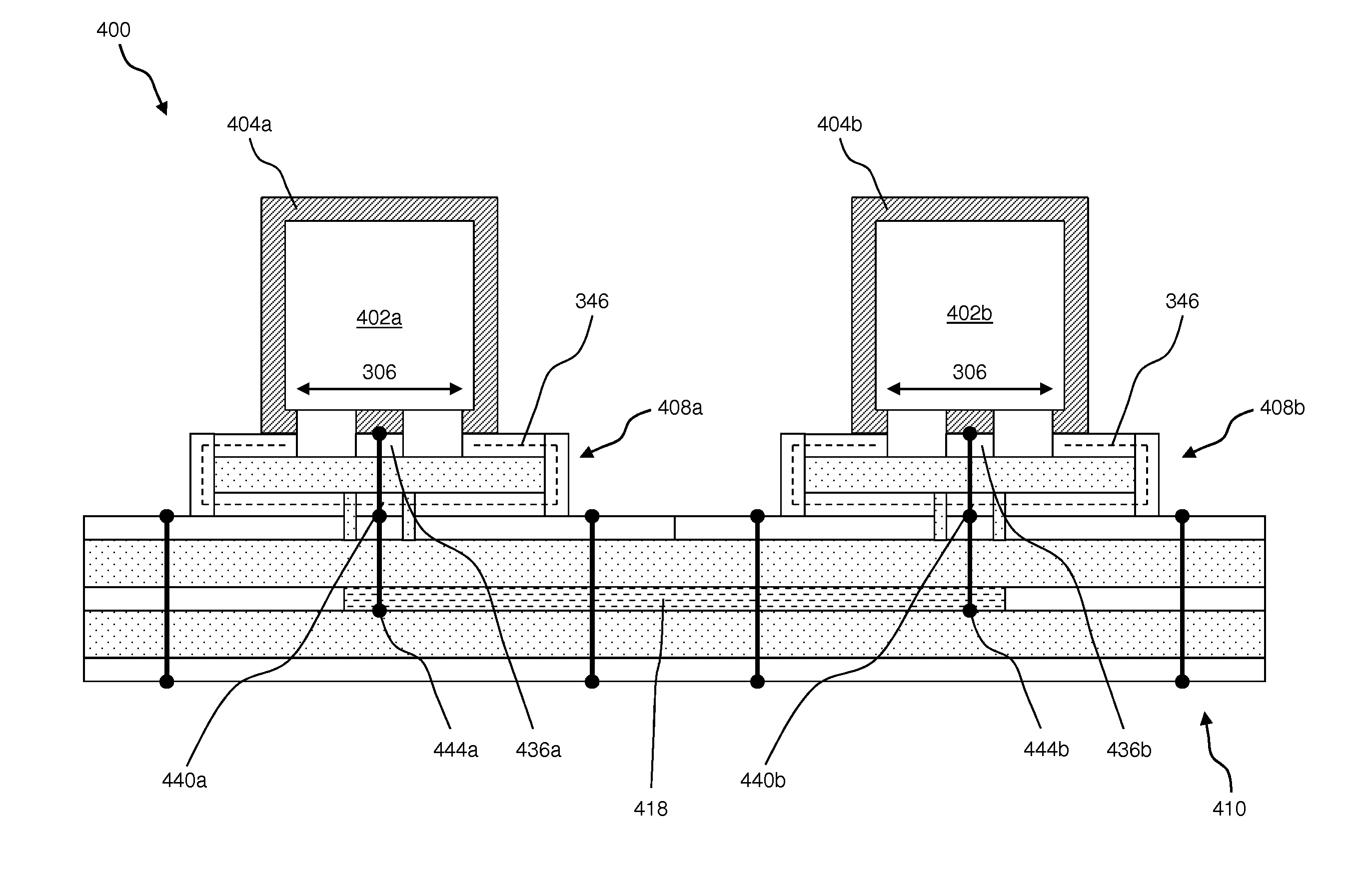

[0030]FIG. 1 is a schematic cross-sectional representation of a multi-mode dielectric filter. In the example illustrated in FIG. 1, the multi-mode filter (shown generally at 10) comprises a dielectric resonator 12, which in the example is in the form of a generally cuboidal “puck” of dielectric material such as a ceramic material having a high dielectric constant. The cuboidal puck of dielectric material 12 is provided on five of its six faces with a coating or covering 14 of an electrically conductive material such as silver or another electrically conductive metal. The coating 14 extends also partially over a sixth face 16 of the dielectric material 12, thereby defining an aperture 18 in the coating 14 on the sixth face 16. One or more coupling structures 20 are provided on the sixth face 16 of the dielectric material to permit a signal to be filtered to be input to the dielectric material 12 and / or to permit filtered output signals to be extracted from the dielectric material 12....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com