Direct steam generation of boiler blowdown

a technology of direct steam and boiler, which is applied in the direction of steam generation using hot heat carriers, insulation, borehole/well accessories, etc., can solve the problems of limiting reuse as feedwater, blowdown presents a problem, and further expensive treatment or inefficient concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

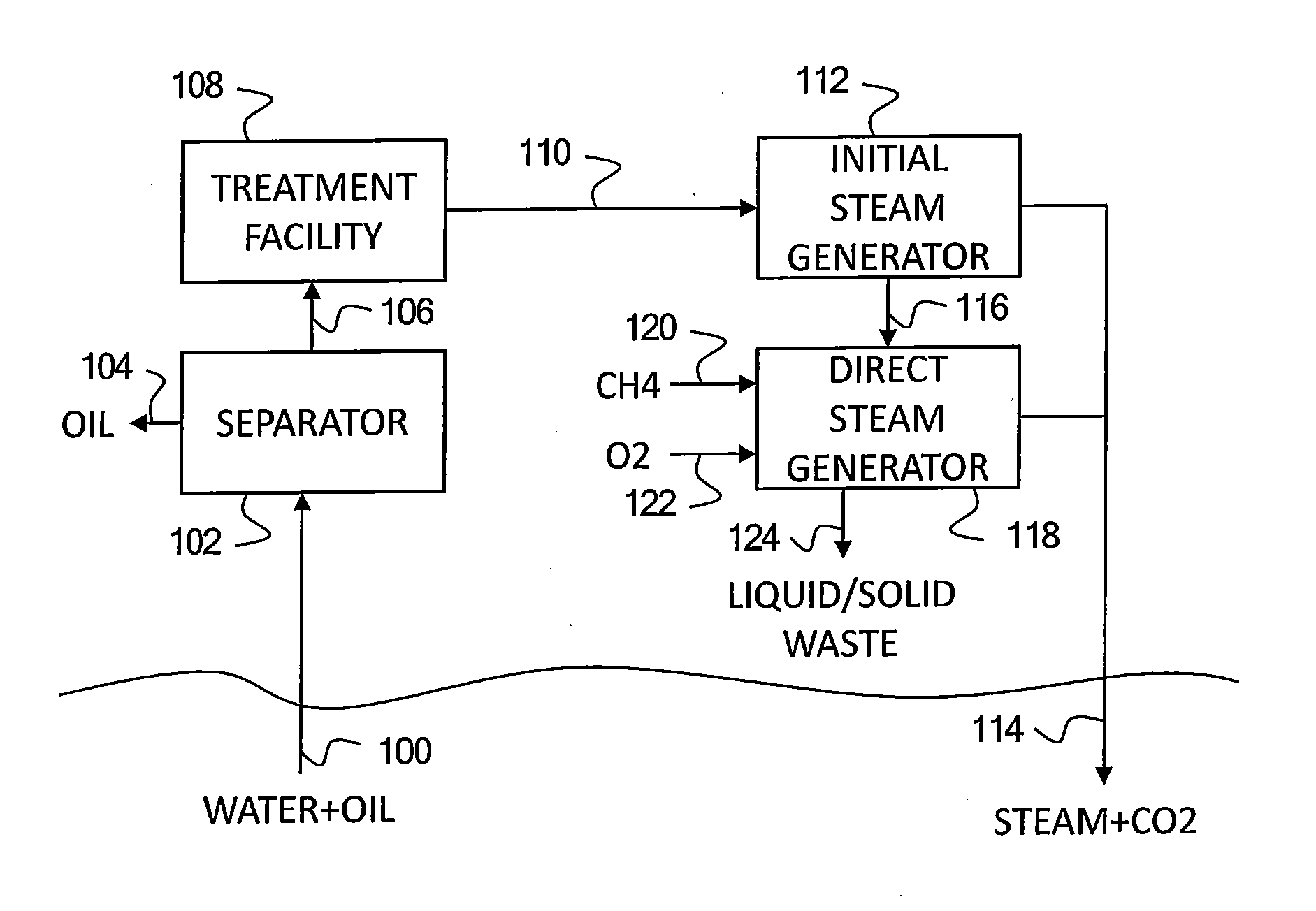

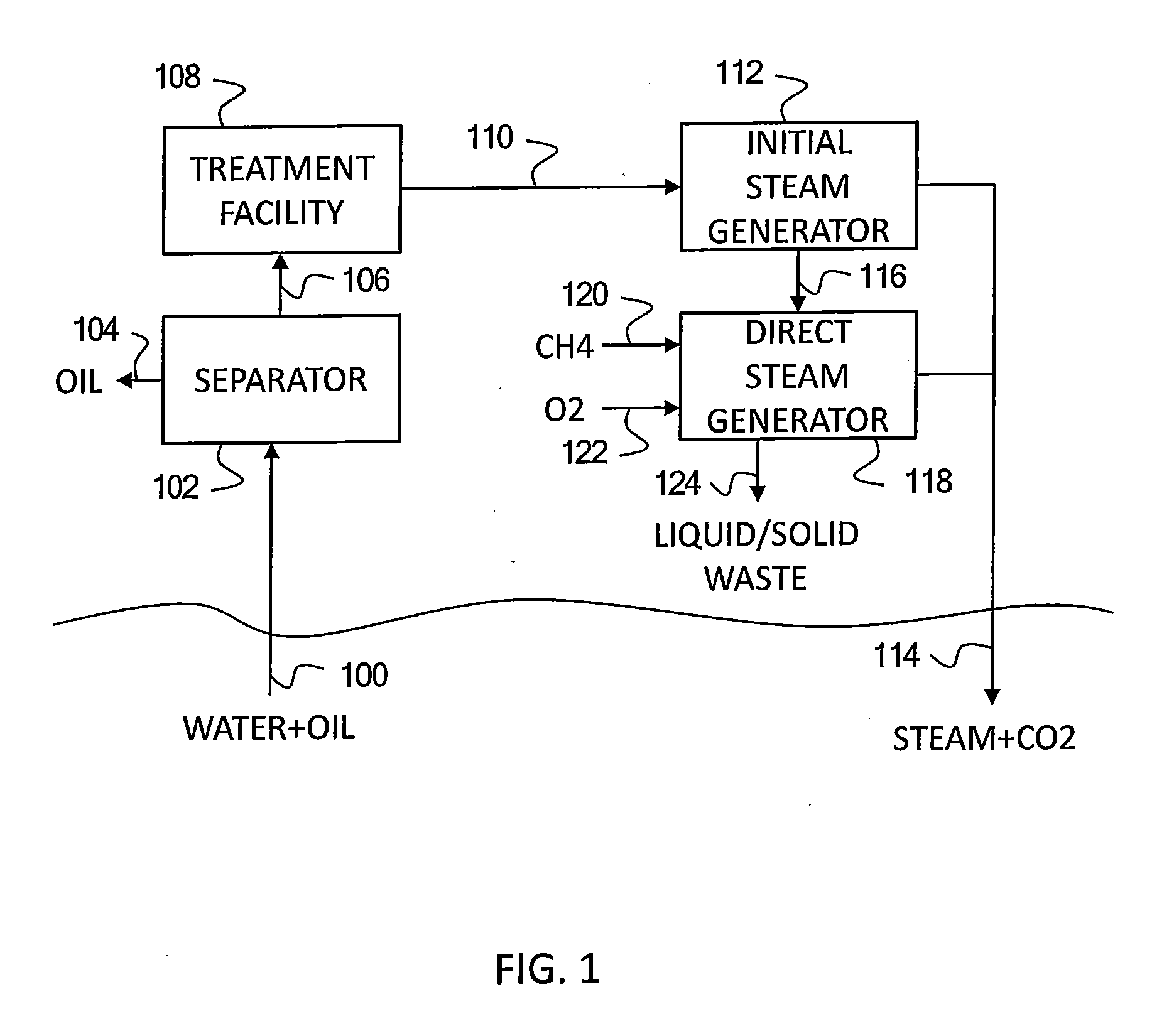

[0013]Embodiments of the invention relate to systems and methods of generating steam from produced water by passing the produced water through first and second steam generators coupled together. The first steam generator produces wet steam in which a liquid effluent with impurities of the produced water passes to the second steam generator. The second steam generator combusts fuel and oxidant in direct contact with the liquid effluent. The first and second steam generators limit fouling and waste while providing a combined steam output that may include combustion products from only the second steam generator.

[0014]FIG. 1 depicts a production well 100, a separator 102, a treatment facility 108, an initial steam generator 112, a direct steam generator 118 and an injection well 114 used in conjunction with heavy oil or bitumen extraction from a reservoir. During the extraction, steam injected into the reservoir through the injection well 114 increases the mobility of the sought after o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com