Burner for exhaust purifying device

a technology of exhaust purification device and burner, which is applied in the direction of combustion types, machines/engines, lighting and heating apparatus, etc., can solve the problems of increasing fuel consumption, difficult ignition of fuel and air mixture, etc., and achieves the effect of easy burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

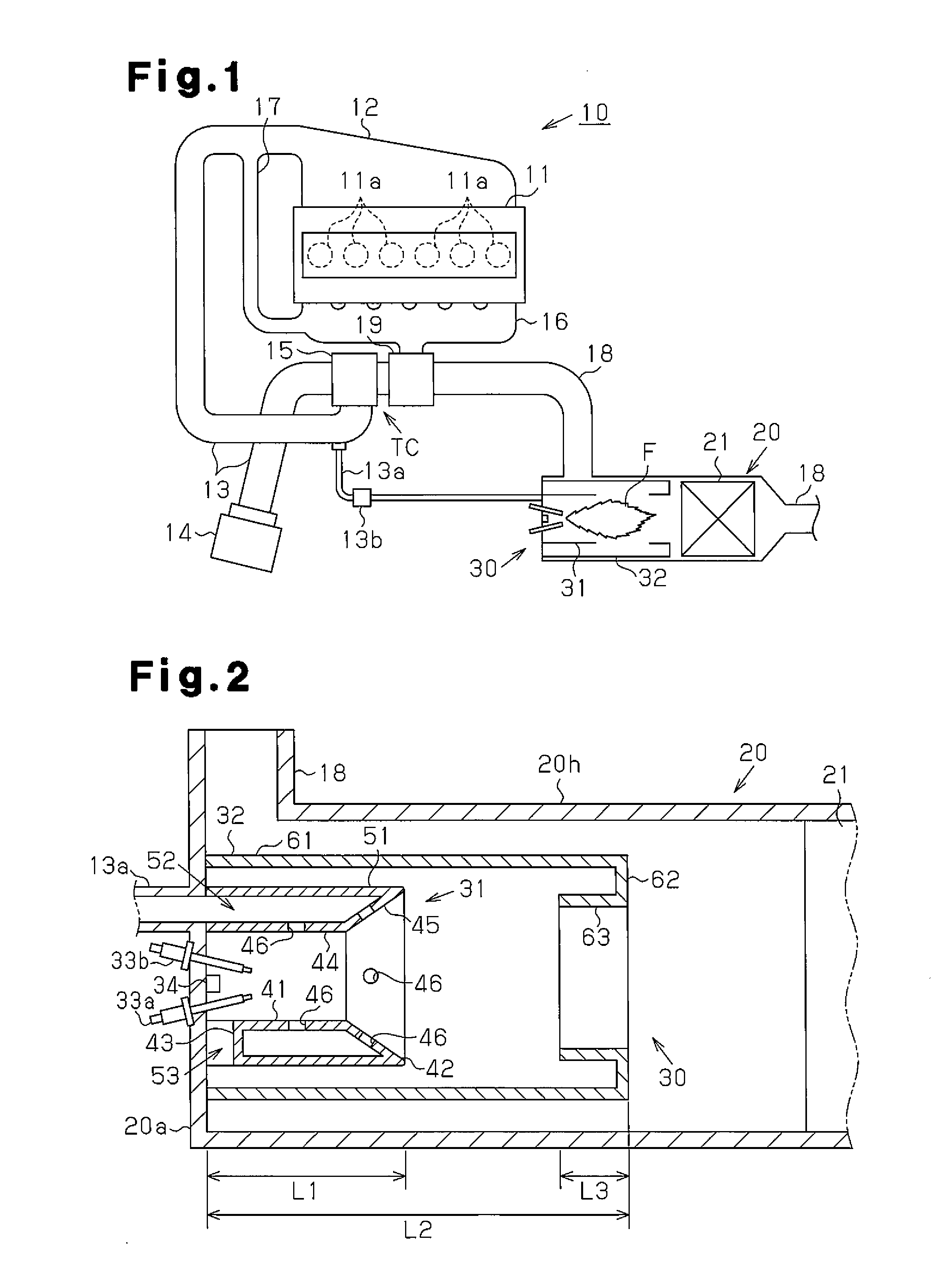

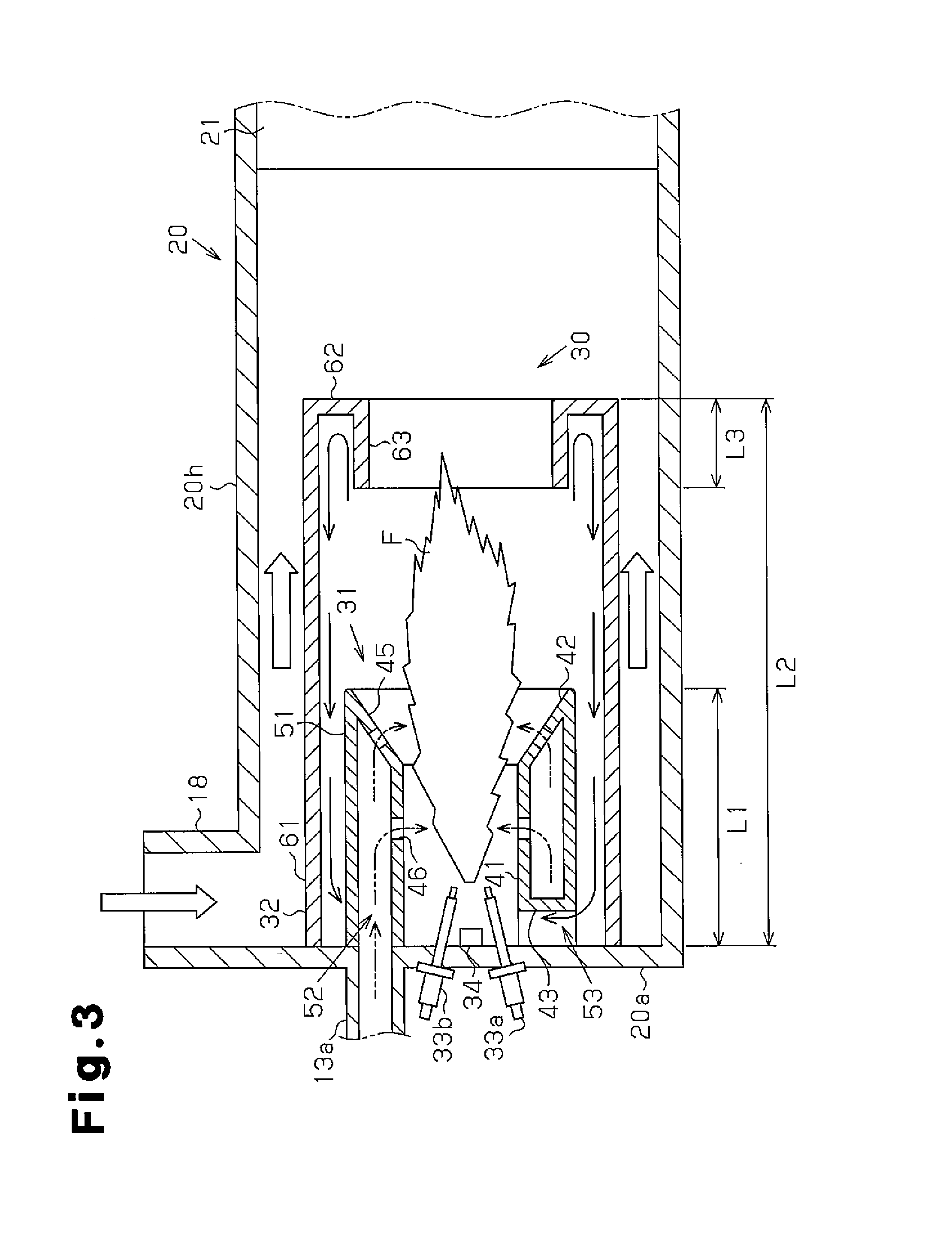

first embodiment

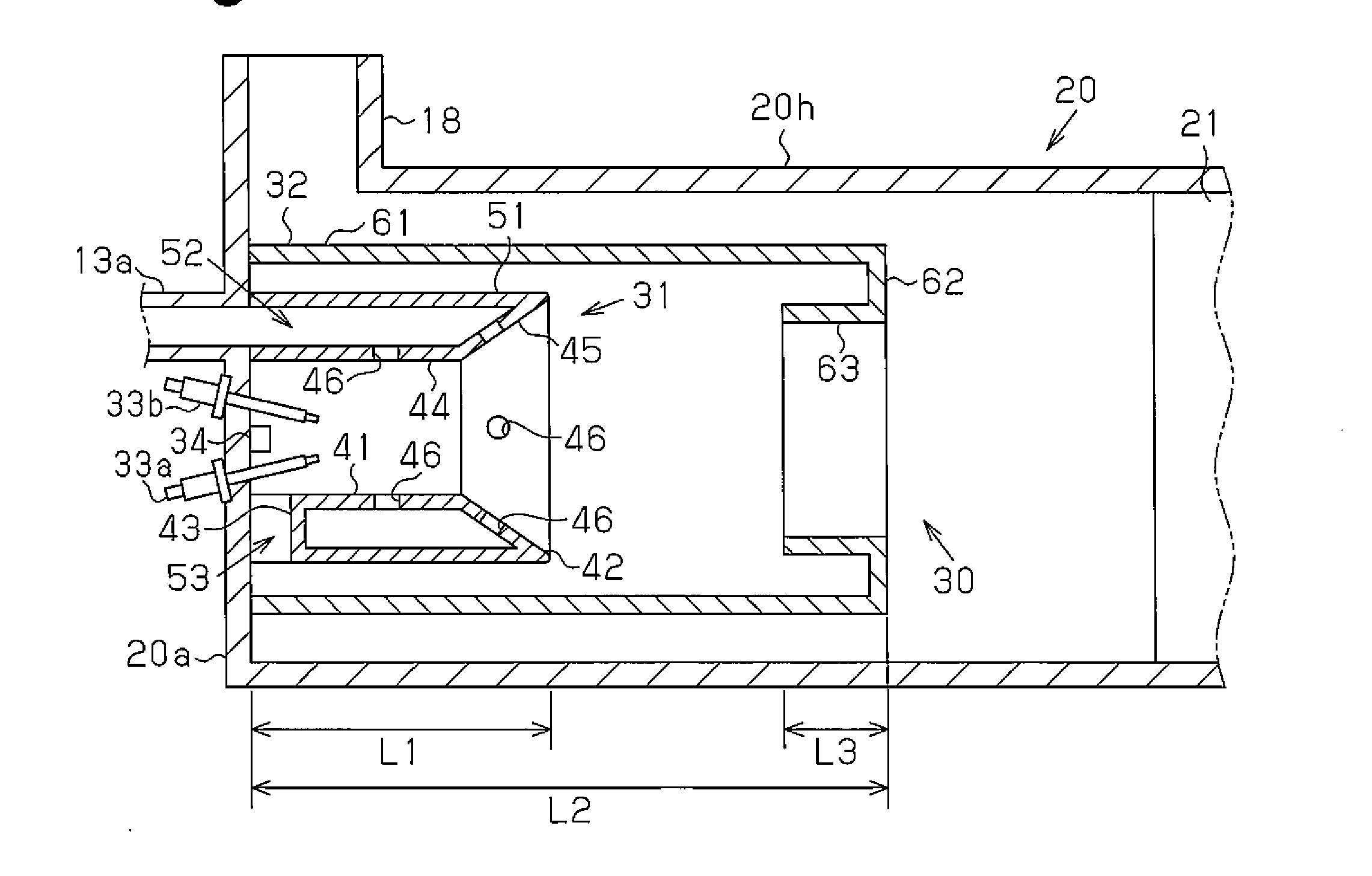

[0034]A first embodiment of a burner according to the present disclosure will now be described with reference to FIG. 1 to FIG. 3. First, the entire structure of a diesel engine including the burner will be described with reference to FIG. 1. The description will focus on a passage for the air drawn into the diesel engine and a passage of the exhaust discharged from the diesel engine, and other parts will not be described. Hereinafter, “upstream” and “downstream” are defined with respect to the direction in which air and exhaust flows in the diesel engine.

[0035][Schematic Structure of Diesel Engine]

[0036]As shown in FIG. 1, a cylinder block 11 of a diesel engine 10 includes six cylinders 11a arranging in a single row. An intake manifold 12, which supplies intake air to each cylinder 11a, and an exhaust manifold 16, into which the exhaust from each cylinder 11a flows, are connected to the six cylinders 11a.

[0037]An intake pipe 13, which is a passage for the intake air, is connected ...

second embodiment

[0078]A second embodiment of a burner according to the present disclosure will now be described with reference to FIG. 4 to FIG. 6. FIG. 5 shows a cross-sectional structure taken along line 5-5 in FIG. 4, and FIG. 6 shows a cross-sectional structure taken along line 6-6 in FIG. 4. The burner of the second embodiment differs from the burner of the first embodiment in the structure associated with the supply of fuel in the burner and the structure associated with the supply of air. Such differences will be described in detail below, and other parts will not be described.

[0079][Structure of Burner]

[0080]As shown in FIG. 4, a burner 70 includes a base body 70b formed to have the shape of a circular plate. The base body 70b is fixed to the basal end of the flame stabilizer 31, which is formed to be cylindrical. The recirculation unit 32 is arranged on the outer side of the flame stabilizer 31 with a gap formed with the flame stabilizer 31, and the basal end of the recirculation unit 32 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com