Pattern fortification for HDD bit patterned media pattern transfer

a technology of patterned media and pattern transfer, which is applied in the direction of patterned record carriers, different record carrier forms, instruments, etc., can solve the problems of affecting and reducing the detection efficiency of soft masking materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]The inventors have discovered a new class of processes for creating a pattern of magnetic properties on a substrate, and apparatus for performing the processes. A structural substrate with a magnetically susceptible layer formed thereon is coated with a metal nitride film, which is patterned to form a mask. The substrate is then treated by exposure to a plasma, which alters magnetic properties of the magnetically susceptible layer according to the pattern of the mask. The mask is then stripped away, leaving a substrate with a magnetically susceptible layer having a pattern of magnetic properties.

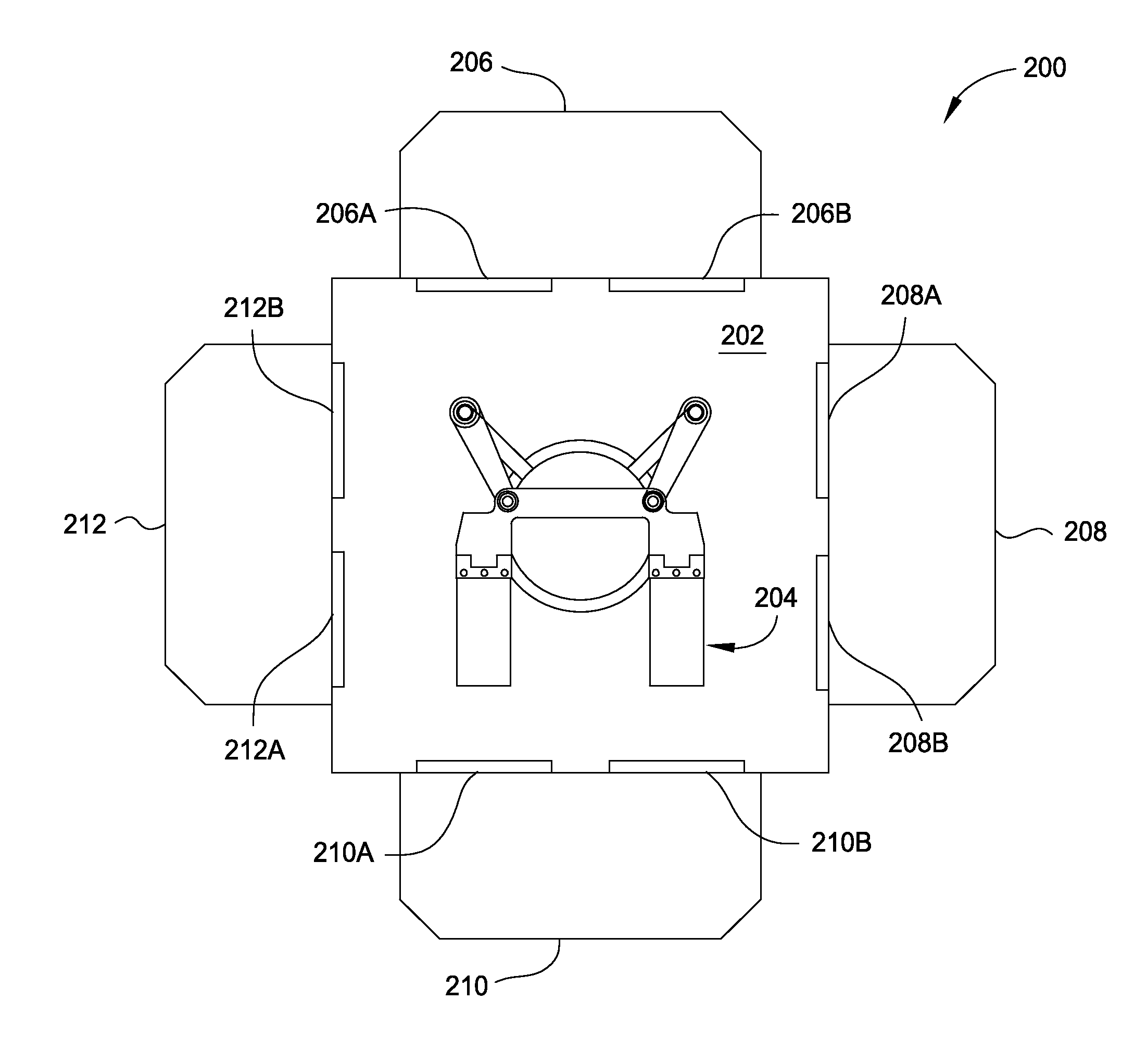

[0016]FIG. 1 is a flow diagram summarizing a method 100 according to one embodiment. The method 100 may be used to form a substrate having a pattern of magnetic properties consisting of a first plurality of domains having a first value of a magnetic property separated by a second plurality of domains having a second value of the magnetic property detectably different from the first val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com