Nonwoven melamine fiber surface preparation and cleaning material

a technology of melamine fibers and cleaning materials, which is applied in the field of preparation of nonwoven surfaces and cleaning materials comprising melamine fibers, can solve problems such as difficult to meet, and achieve the effect of reducing breakage of melamine fibers and much better cleaning materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

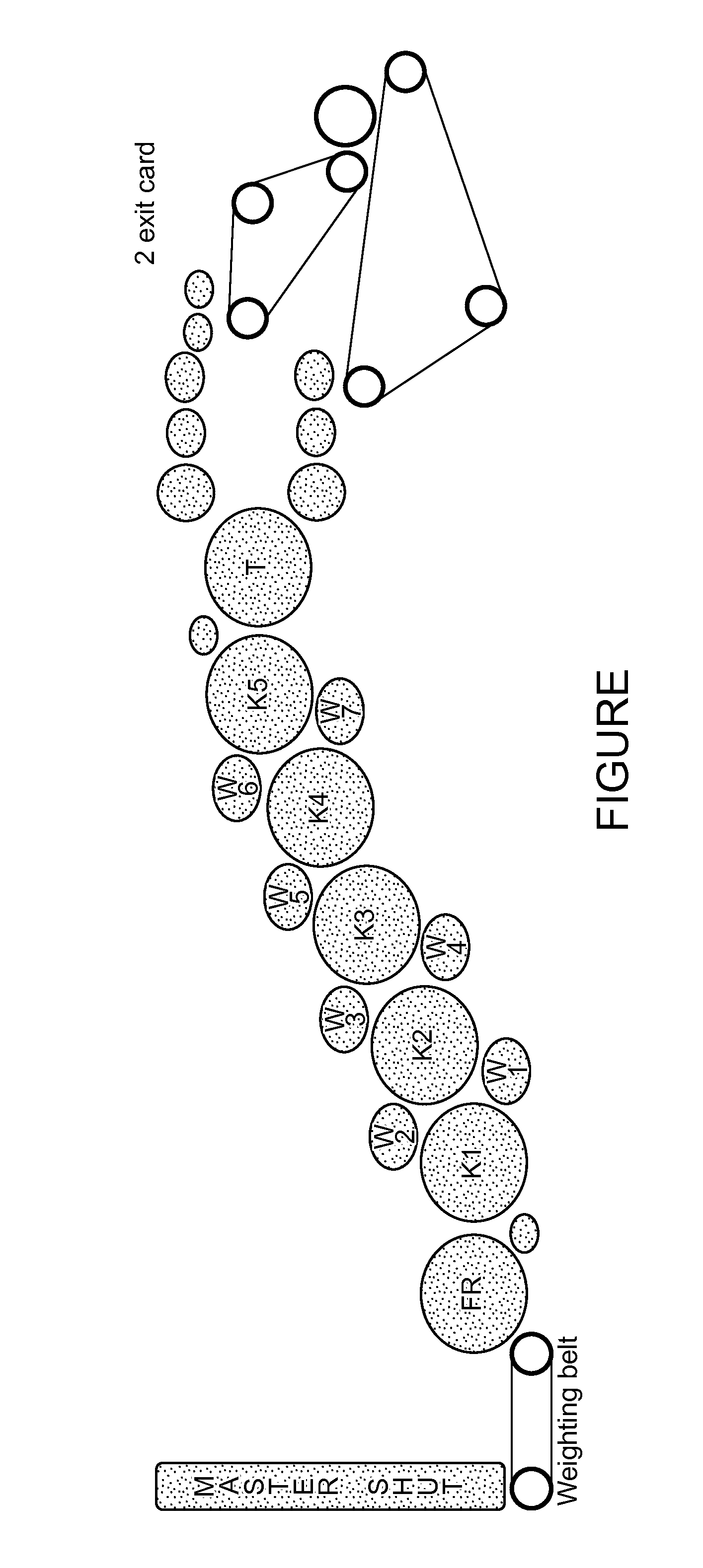

Method used

Image

Examples

Embodiment Construction

[0018]The invention relates to a cleaning or surface preparation substrate containing melamine fibers combined with other fibers in a spunlace needlepunch or wet laid nonwoven process. Fibrous melamine is well suited for use in a wide variety of surface preparation, scrubbing, cleaning and wiping applications including household, janitorial, food service, industrial, medical, dental, automotive, flooring or any other end uses where a pliable and effective removal or cleaning substrate is needed. While this substrate can be produced from a variety of fabric formations including airlaid, wetlaid, stitch bond, melt blown and others, a preferred needlepunch nonwoven configuration comprises melamine fibers blended with fibers like viscose rayon, Tencel®, polyester, nylon, wood pulp, polypropylene, bicomponents and others.

[0019]Melamine is an organic base and a trimer of cyanamide, with a 1,3,5-triazine skeleton. Melamine fiber is a manufactured fiber in which the fiber-forming substance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| lengths | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com