Seawater infiltration method and water infiltration intake unit

a technology of water infiltration and intake unit, which is applied in the direction of water cleaning, filtration treatment, and membranes, can solve the problems of increased turbidity, high initial cost, and water intake must be stopped, so as to prevent clogging, reduce the scale of construction during installation, and facilitate maintenance. effect of system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0045]An embodiment of the present invention is described in detail below, using FIG. 1 to FIG. 13.

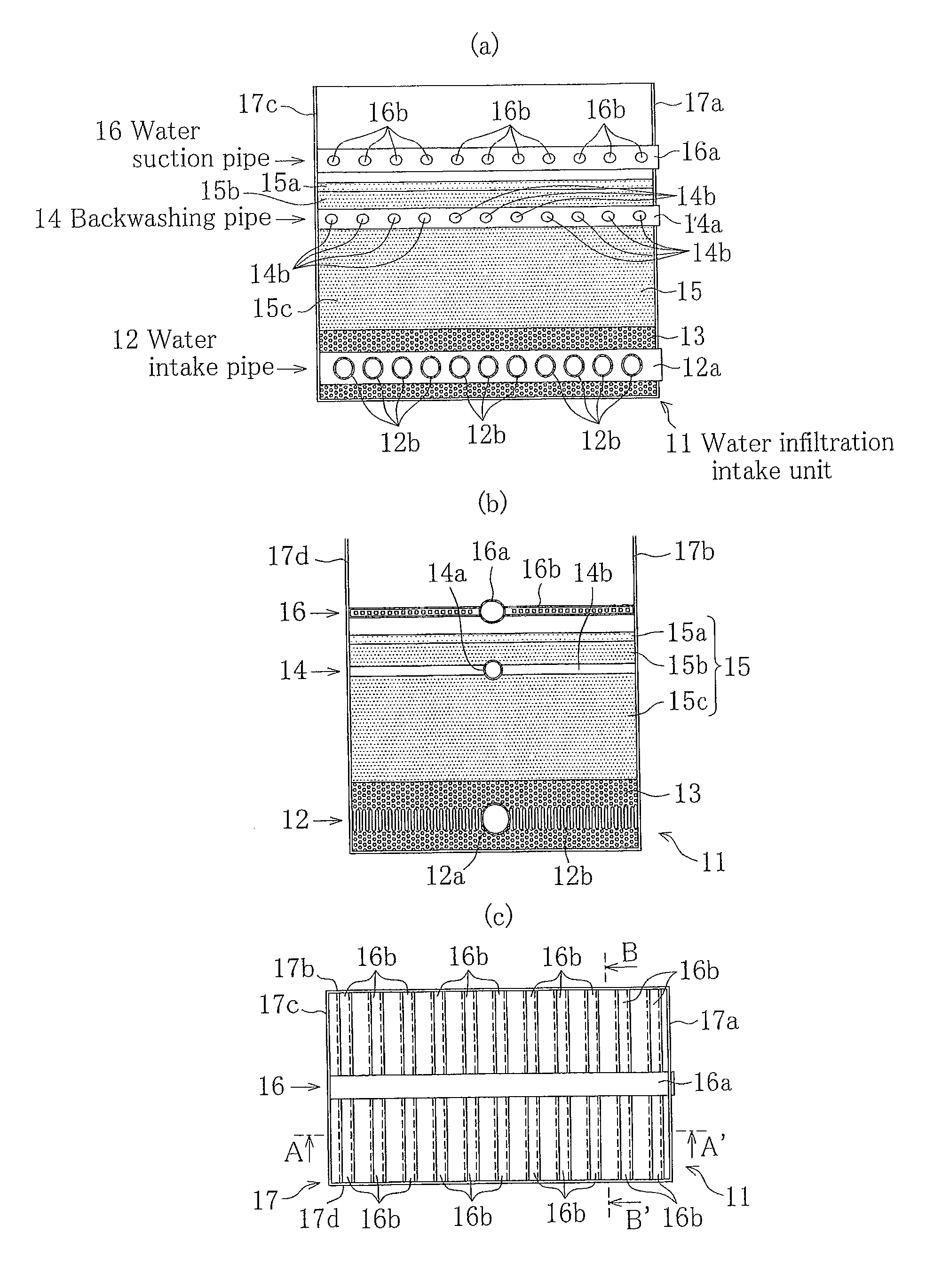

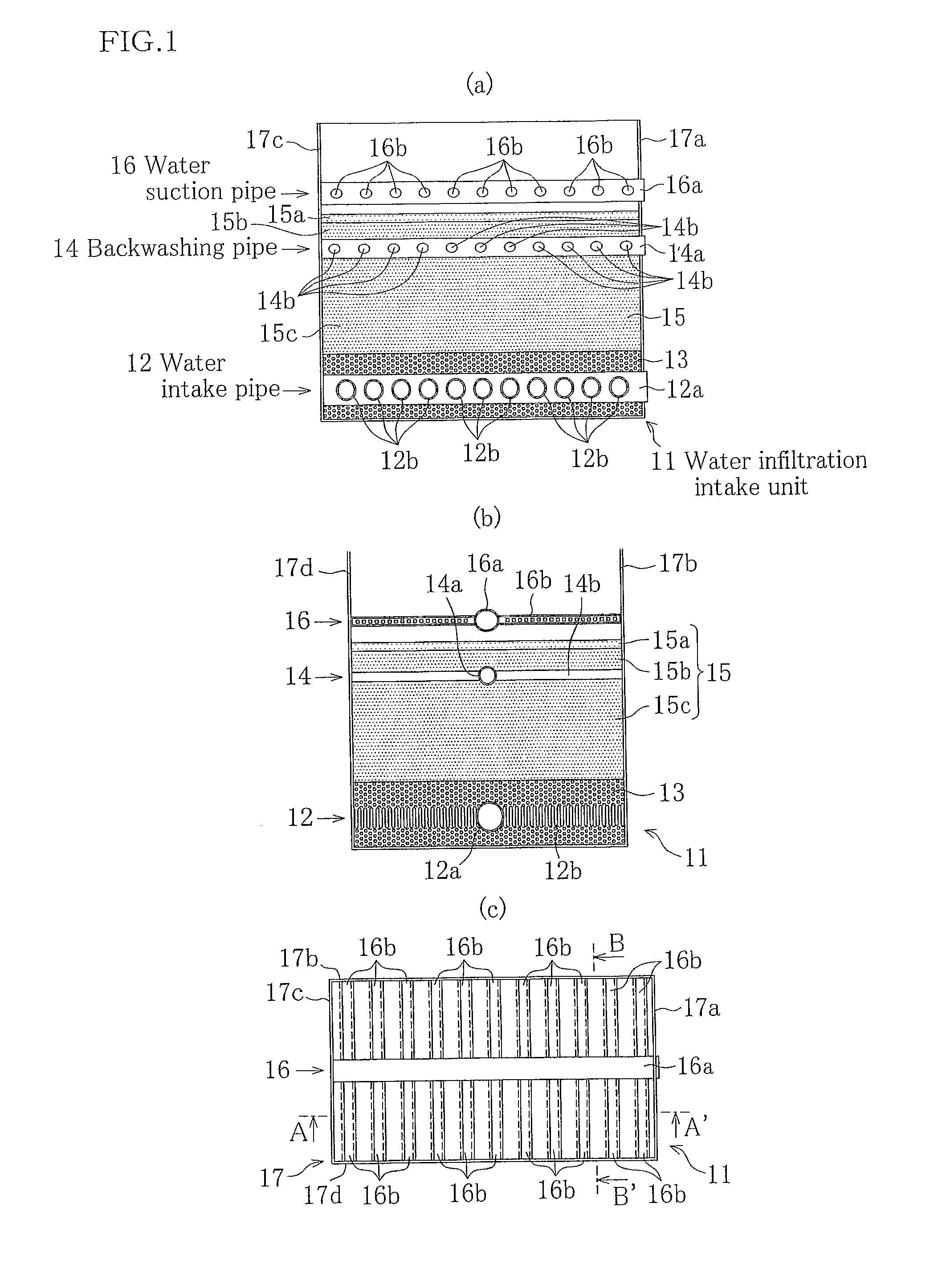

[0046]FIG. 1 is a drawing illustrating an example of a water infiltration intake unit 11 used in the seawater infiltration method of the present invention.

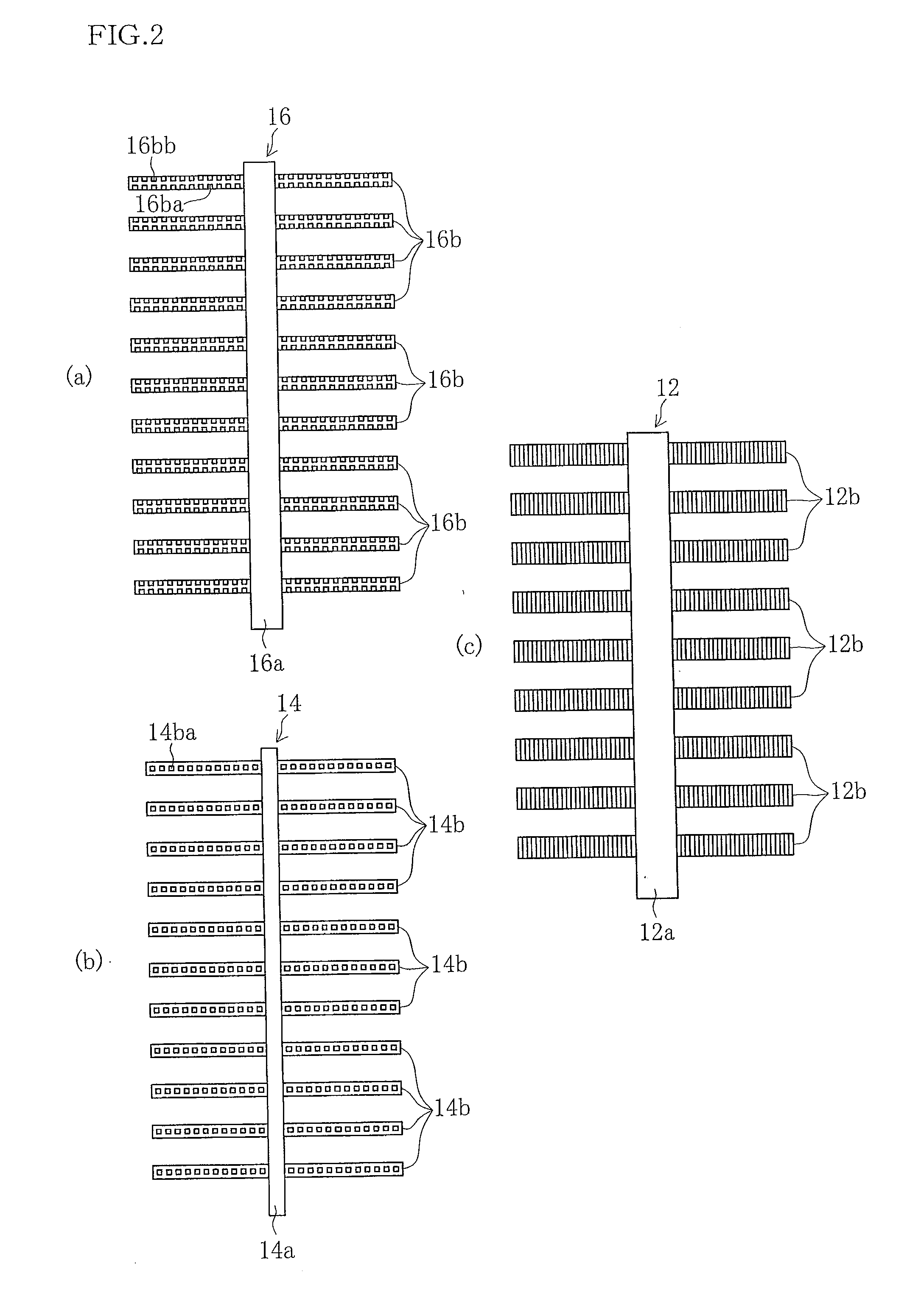

[0047]In FIG. 1(a) and FIG. 1(b), Reference Numeral 12 is a water intake pipe embedded in a gravel layer 13 which forms a deep layer of a sand filtration layer on the ocean floor. The water intake pipe 12 is formed from a main pipe 12a and a plurality of branch pipes 12b which branch in a direction crossing the main pipe 12a. Embedded in a sand layer 15 formed from intermediate layers 15b and 15c and a surface layer 15a of a sand filtration layer is a backwashing pipe 14 formed from a main pipe 14a and a plurality of branch pipes 14b which branch in a direction crossing the main pipe 14a.

[0048]In FIG. 1(c), Reference Numeral 16 is a water suction pipe formed from a main pipe 16a and a plurality of branch pipes 16b. As shown in FIG. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com